April 2010

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

April 2010 |

[an error occurred while processing this directive] |

|

|

|

In a world in which people, places and things are becoming increasingly connected, your building’s energy systems need to be connected as well. Unfortunately, less than 2 percent of the 80 billion square feet of existing commercial real estate in the U.S. take advantage of distributed lighting controls to save energy and reduce costs and carbon emissions.

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

Lighting alone accounts for 30 to 40 percent of a

commercial building’s electrical use, so the inability to control lighting

through a distributed intelligent network to reduce costs is a tremendous missed

opportunity.

Wiring and installation costs are often cited as major barriers to deploying

advanced controls in existing buildings. Adura® Technologies, which designs and

manufactures turn-key, full-featured digital lighting and energy management

control solutions, overcomes this barrier by connecting lights with robust,

secure distributed wireless controls that lower electricity costs 30 to 70

percent, while enhancing the long-term value and viability of buildings. By

going wireless, the cost drops dramatically and disruption to building occupants

during installation is minimized.

The Adura LightPoint System™ (ALPS™) control platform provides unprecedented management over commercial building lighting. A key component of the system is the Adura Light Controller™ which can control one or more ballasts or other lighting loads to provide the ultimate in granular control. No longer does an entire floor of lighting need to be wasting energy only because a few lights are needed. The distributed control platform communicates with field devices such as switches, motion sensors, light sensors and our enterprise web software to provide flexible scheduling, daylight harvesting, occupancy control, personal control and load shedding.

Beyond controlling lighting, the ALPS Enterprise Database tracks and monitors energy use, carbon footprint and peak load and shows users when and where they are using energy. It also can provide valuable predictive maintenance information including reports on failed lamps and ballasts.

ALPS is easy to install and use. In fact, it takes just minutes to install our controller or sensor in a light fixture or switch. The Light Controller even comes with magnets for tool-free installation.

Existing daylight and motion sensors can be wirelessly integrated into the system or, for ease of installation, We can supply the devices, which can be added “lick-and-stick”- style to the network. The sensors are battery-powered with a minimum five year life.

Wireless Mesh Network

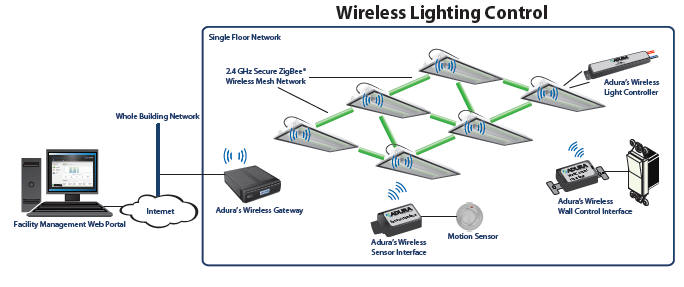

The ALPS platform is a distributed wireless mesh network, based on

the ZigBee® protocol. Field devices are connected to the Internet by a gateway.

That means that, at an enterprise level, control scales from a single device to

a room, a floor, an entire building or even a campus.

Mesh networking provides highly reliable control by

enabling multiple paths for the data to flow between sensing and control

elements on the network. The mesh is also self-healing so that if one path

fails, the network will re-route the data to ensure the integrity of the

communications.

Additionally, a ZigBee mesh network is easily expandable. Each new node is

automatically discovered and can be configured with the appropriate control

action.

Finally, if a facility is renovated or walls are moved, the entire control

network can be easily reconfigured from a central location with no need for

rewiring.

ALPS is also light source agnostic – it can work with fluorescent, incandescent,

CFL, HID, LED or any other type of lighting.

Energy Management Dashboard

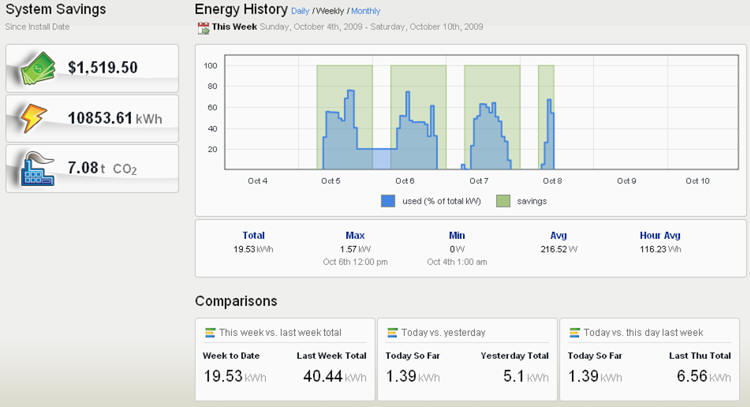

A powerful feature of Adura’s browser application is an energy dashboard

that enables a wide range of management options. The dashboard provides

immediate and graphical feedback on energy savings for an entire system or a

specific area. Energy savings can be viewed in terms of monetary savings, carbon

emissions or kilowatt hours.

ALPS enables facility managers to implement dynamic lighting control, including

scheduling by time or event, occupancy, daylight, task-tuning and personal

control. There is even an astronomical clock that can be used for automatic

seasonal adjustments.

Lights can be dimmed, where such capability exists, or individual ballasts in

fixtures can be shut off. Such granular control allows for tremendous lighting

energy savings. Spaces can frequently be lit at levels well below their

installed capacity and are often more comfortable for the occupants as a result.

While central control is critical to system efficiency and effectiveness, ALPS

also provides local overrides to meet personal requirements. Individuals can be

given the use of simple wall switches, personal remotes or web aplets to adjust

lighting to their immediate needs. Since ALPS provides an individual IP address

for every controller, any device can be controlled by authorized users through a

secure web interface. For example, someone working in a cubicle late in the

evening when the rest of the office floor is empty can turn on lights just in

his or her area.

Just as important for management purposes, ALPS has a full-featured enterprise

application that collects historical information for analysis of energy

consumption, provides administrative and user security levels, performs

administrator override of all system functions, sets up lighting groups

behaviors, alerts users of lighting and system alarms and has a rich set of

reports.

All data in the network is encrypted and there are extensive security features

for user access to the system. Management can set access levels from full

administrative control to a single user being able to control a single light

fixture

[an error occurred while processing this directive]

Demand Response

Another key ALPS feature is its ability to support automated demand response via

a signal from the utility or by an e-mail where the system administrator can set

the demand response level. The system can be configured such that there is

limited user override capability during a demand response event.

This same functionality can be used to manage peak demand. Users can program the

system to receive a signal from their smart meter when a peak consumption level

is about to be exceeded and automatically execute lighting control to manage the

peak load.

Beyond lighting controls, ALPS provides a platform for the management of other

building functions. Adura already has partnered with Cypress Envirosystems to

provide HVAC monitoring and control. Since lighting and HVAC comprise 60 percent

of a buildings energy use, the savings potential is significant – up to 50

percent, according to estimates by both companies.

In fact, just about anything that can be outfitted with a sensor or controller

can be integrated into the system, including air quality monitors, HVAC

components, security systems, fire extinguishers, etc. That’s our long-term

vision – a total building system management system, with mass controls at the

enterprise level that can be tailored to a facility’s specific needs.

Adura has proven that its system works in numerous case studies.

In 2008, the California Energy Commission’s Public Interest Research Program

issued a technical brief entitled “Wireless Lighting Controls Make Retrofits

Practical” in which it concluded: “An innovative wireless light-control,

monitoring and management system developed by Adura Technologies is easy to

install, cost-effective and can provide significant energy savings.” The

conclusion of the study came from work that a team, including Adura’s founders

and the University of California, Berkeley, performed at two libraries on the

campus. Adura’s wireless control system was installed in facilities where lights

burned 24 hours a day because the only controls were in circuit breakers in a

locked closet or near a skylight. Our wireless solution showed a 65 percent

reduction in cost and resulted in a nearly instant payback.

In 2009, we completed a project for Webcor Builders

at one of its facilities in Hayward, Calif. The 2,300-square-foot open space was

occupied by a mix of project and administrative personnel and the occupancy

pattern changed constantly. Many employees were in the office part of the day,

but in the field the rest of the time. With no individual controls for the

overhead lighting, lights burned at full brightness all day. We installed

wireless controllers in each fixture and gave remote control devices to each

cubicle occupant. As a result of employees turning lights on when needed and off

when they left, the facility saved 65 percent on lighting.

In two other studies last year by Pacific Gas and Electric, Adura lowered energy

use in at an Alameda County Water District facility by 70 percent and met

utility company requirements for demand response.

In summary, distributed wireless mesh controls provide exciting new

opportunities for improving energy use efficiency in commercial buildings. They

are particularly attractive for existing buildings, where retrofitting with

traditional wired systems can be expensive and disruptive.

Adura’s solution is cost-effective for retrofits, renovations and new

construction. With the wireless solution, building owners, tenants and facility

managers can implement energy efficiency and load curtailment strategies to

reduce operating costs and carbon emissions at a third of the cost of

traditional control systems.

About The Author

Jack D. Bolick is President and Chief Executive

Officer of Adura Technologies and is in charge of driving both the commercial

and technical growth and development of the company. Adura is focused on

wireless management controls for commercial buildings and creating a platform

that provides other building energy management systems as well.

Bolick joined Adura May 2009 after retiring as President of Honeywell Process

Solutions (HPS), where he led a global organization of more than 13,000

employees with $3 billion in annual sales and turned the company into a leading

process automation solution provider.

He has had a career in semiconductor and manufacturing materials supply, global

marketing and manufacturing strategies for high-growth markets. He has Six Sigma

Black Belt and Green Belt certifications and was awarded the 2008 Frost and

Sullivan “Lifetime Achievements” award in the automation industry.

He was Vice President and General Manager of the AlliedSignal and Johnson

Matthew consolidation that became Honeywell Electronic Materials in 1999. Prior

to the consolidation, he worked at Johnson Matthey Electronics for eight years.

He also has worked at International Resistive Co., Analog Devices, Inc.,

Burlington Industries, Inc. and United Merchants and Manufacturing, Inc.

Bolick has a M.S. in industrial engineering, with a concentration on systems

analysis and design, from North Carolina A&T State University.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]