April 2010

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

April 2010 |

[an error occurred while processing this directive] |

|

|

|

When you say the term SmartGrid, you could be talking about any number of applications and technologies. After all, SmartGrid is simply the concept of utilizing power (the Grid) more efficiently. This means managing loads smartly to remove excess demand. It means managing Generation to create power as cost effectively as possible. It means transmitting power to where it is needed with as little loss as possible.

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

Customer involvement is essential. There are many “SmartGrid” initiatives focused on the integration of customers into the SmartGrid including the SGIP - Home to Grid (H2G), Building to Grid (B2G) and Industry to Grid (H2G) Domain Expert Working Groups managed by NIST (National Institute of Standards and Technology). These initiatives are designed to engage customers of all types for the purpose of managing power use more effectively, either through voluntary means (homeowners changing their habits based on variable electric rates) or through Demand Response controls between Power providers and users, enabling the delicate balance of generation vs. demand. In times of stress (when generation cannot meet the load), utilities have the ability to load shed (reduce demand on the system by shutting off appliances (home systems), or shutting down major users (Industrial users with load management agreements). Alternatively, remote power generation – emergency generation, typically idle at major facilities and used during power outages, may be brought on-line to supplement power to the grid.

There are several phases which lead to the new world of the SmartGrid. Today, we are in one of the earliest phases, an instrumentation phase adding the ability to assess power utilization in real-time. The majority of “Stimulus Money” earmarked for the SmartGrid is being used to enhance Power monitoring with Smart Meters that can be read remotely and in real-time.

This, of course, requires enhanced communications. While there is no one “SmartGrid Protocol”, there are a wide range of protocols that can and are applied to SmartGrid applications. For a list of protocols being highlighted for SmartGrid use, see the NIST Framework and Roadmap for Smart Grid Interoperability (NIST Special Publication 1108).

The world of SmartGrid communications will likely break down into two major categories, the consumer (home) and the industrial (Building and Industry to Grid) markets. These markets will be served through very different technologies due to their needs and the costs involved. The consumer marketplace will be served through a combination of Smart Meter Gateways, and Internet Interfaces combined with appliances designed to operate intelligently, based on homeowner preferences or remote utility commands. These systems need to remain as inexpensive as possible for mass adoption. They need to connect simply, avoiding installation costs. They will likely make extensive use of wireless technologies.

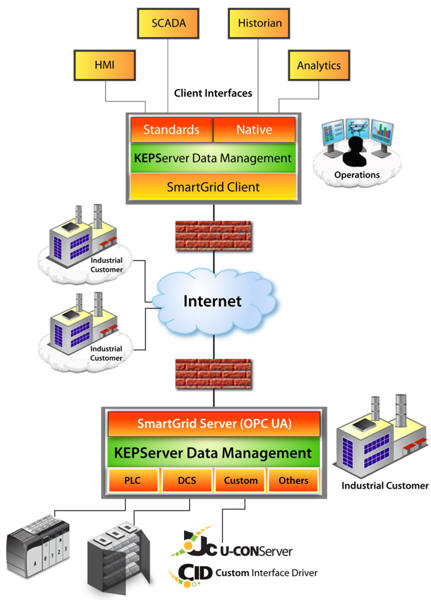

Typical example of an Industrial SmartGrid Gateway connected to a Utility for Load Management

Industrial applications have very different requirements. They require the coordination of existing automation systems. They require interfaces to legacy systems through a wide range of existing protocols. They also require a higher level of interaction, real-time communications enabling B2B communications for automation. The communications in the industrial market will be for Demand and Response (DR) purposes. These controls will manage both the shedding of loads to manage power availability as well as the remote control of auxiliary generation to augment power production. The I2G space will require an I2G Industrial Gateway, bridging internal systems and communication protocols for external access by a coordinating authority (the power utility or a power management authority).

[an error occurred while processing this directive] While security is extremely important in both scenarios, it will be a critical requirement in the Industry to Grid space, where controls can manage large loads the compromise of one connection will have a major impact. Many of the “Legacy” protocols were developed prior to our current “Cyber” world and are simply not suitable for an Internet based communications architecture.

One protocol in particular will be worth watching as the SmartGrid architectures unfold. The automation marketplace has developed standards for software interoperability as early as 1996. This standard is called OPC and is managed through the OPC Foundation. The OPC Foundation is supported by over 400 member companies and at this time, all major automation software products support OPC as their data interoperability standard. In 2006, the OPC Foundation began the specification of its next generation of technology, named OPC UA (OPC Unified Architecture) – delivering support for the latest technologies and “Unifying” the earlier specifications that were developed for different forms of information; OPC DA for Data Access, OPC AE for Alarms and Events and OPC HDA for Historic Data Access.

OPC UA delivers technology that directly targets the features and benefits required in SmartGrid applications. These include Platform Portability – the ability to add OPC UA interoperability to all manner of system from field devices to central control systems, Standards based security – RSA data encryption and x509 Certificates for connection authentication, and the support for all forms of data including complex objects – collections of data based on proprietary vendor standards or industry standards such as ISA-95. Ratified by the OPC Foundation TAC (Technical Advisory Committee) in 2009, OPC UA products are already in the market with many more under development and arriving in 2010.

About the Author

Roy Kok is the Vice President of Marketing and Sales for Kepware Technologies.

Kepware is a leading provider of automation protocols and communications

interoperability.

Roy joined Kepware in 2007. Previously, Roy managed Product Marketing and

Product Management of GE Fanuc’s HMI/SCADA solutions, primarily CIMPLICITY and

iFIX HMI/SCADA products and associated communication drivers. Prior to GE Fanuc,

Roy held key positions with notable automation industry companies including

Intellution, VenturCom, Sytech, Nematron, Intec Controls, and Kaye Instruments.

As of 2007, Roy has over 30 years of experience in the automation industry.

Roy has a Bachelor’s degree in Electrical Engineering from Northeastern

University in Boston Massachusetts.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]