April 2010

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

April 2010 |

[an error occurred while processing this directive] |

|

|

Nathan Rothman |

As we approach the 40th anniversary of Earth Day on April 22, 2010, the goal to “go green” will be top of mind for many in the building industry. Building owners and operators are well aware that the simplest way to be green is to reduce what is currently being used. The difficulty arises when attempting to use conventional methods of energy reduction and expecting to meet ever-higher standards of what it means to be “green.”

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

HVAC is a prime example, as it typically accounts for 40 percent of a building’s

energy use. Conventionally, HVAC systems have been designed to constantly

operate components at full speed, even when the building was operating at less

than full loads. For instance, in San Diego the highest-ever recorded

temperature was 112 F. Therefore, HVAC systems in San Diego are designed to meet

cooling needs on the hottest day of the year - 112 F - plus a margin of safety.

In reality, however, buildings in San Diego only need to run at full capacity

less than 4 percent of the year. That means that for the 96 percent of the year

when temperatures fall below the highest range, the HVAC system is still

operating at full speed, wasting valuable energy.

In response, solutions such as variable frequency drives (VFDs) that make it

possible to run all the components within an HVAC plant (e.g., chillers, pumps,

fans, etc.) at variable speeds, are now integral in the design of new or

upgraded HVAC systems. VFDs can’t do it alone, however; achieving the highest

level of energy reductions possible in all-variable speed plants also requires

effective execution of advanced control strategies.

Conventional methods of HVAC design and operation rely on engineered solutions,

wherein a controls engineer specifies control sequences unique to a particular

facility that are then programmed directly into a facility’s building automation

system (BAS). Custom engineered solutions by nature carry risk, as they are

unproven, can take weeks or months to develop, and require hands-on functional

testing to verify the system is working as designed.

By taking advantage of information technology advances, it’s possible to

overcome the limitations of custom-designed and custom-programmed building

control. Standardized software solutions are available today that can apply

sophisticated control methodologies to the efficient operation of HVAC systems.

As open-protocol solutions, they work with virtually any make and model of BAS

and equipment, and are fast to integrate. In addition, standardized solutions

are tested and proven in the field to work, so building owners and operators can

be confident that they’ll realize the energy reductions they expect. In

addition, the use of standardized software makes it possible to track real-time

and historical data about a system’s performance. That information can be

accessed via the Web in an easy-to-use format, helping to ensure predictable and

reliable energy reductions that last year-after-year.

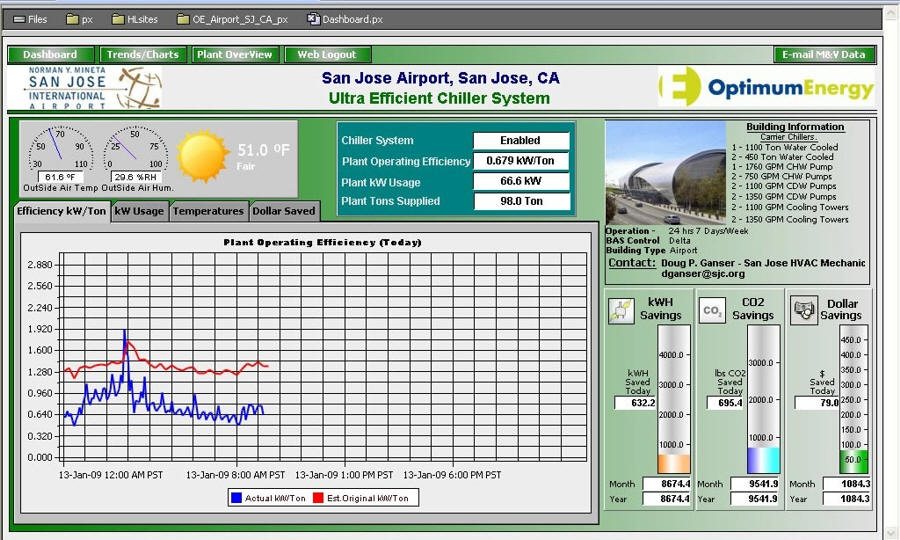

Software Saves Mineta San José International Airport 1

Million kWh a Year

The use of Optimum Energy’s OptimumHVAC software at the Mineta San

José International Airport (SJC) provides a real-world example of how a

standardized software solution has been able to significantly reduce HVAC energy

and carbon output each year.

Located in California’s third-largest city, SJC is the forty-first busiest

airport in the U.S., handling an average of more than 9 million passengers a

year. As part of its comprehensive terminal modernization program, SJC committed

to implementing energy efficiency technologies that would help reduce operating

costs and its carbon footprint for years to come. The improvement program, on

schedule to be completed in 2010, includes construction of a new Terminal B and

its 380,000 square foot North Concourse, as well as upgrades to Terminal A.

Working with engineering services firm WSP Flack + Kurtz, SJC determined that

energy efficiency improvements to its HVAC system’s central chiller plant would

lead to significant savings. A new, 1,100-ton chiller unit was added to the

airport’s central plant. Additionally, upgrades were made to two existing

450-ton chillers, including installation of VFDs and a new cooling tower, and

adjustment of the existing VAV air handling units. On top of the physical

upgrades, OptimumHVAC was also implemented via the airport’s BAS. The software’s

patented control algorithms automatically and continuously adjust the speed of

each component within the airport’s HVAC system so that it provides the required

output, based on real-time load conditions, using the least amount of energy. In

many cases, this involves operating multiple chillers at slower speeds instead

of running one chiller at full speed.

[an error occurred while processing this directive] With OptimumHVAC, airport building operators also have access to a Web-based

measurement, verification and management service that provides the real-time and

historical operating data they need to maintain the plant and ensure energy

reductions persist over time. In the first year of operation, SJC realized a

savings of 1,256,000 kWh of energy, which equates to a reduction in operating

expenses of $188,000, and a carbon footprint reduction of more than 1,353,000

lbs of CO2. The chiller plant’s average kW/ton was reduced to 0.6 kW/ton from

1.25 kW/ton, a reduction of 51%.

The energy and carbon reductions qualified SJC for utility rebates, and the

airport plans to pursue green building certification. And with the incremental

cost that comes with software solutions, SJC saw a full project payback within

18 months.

About the Author

Nathan Rothman, B.E.P., CSDP, is the founder

and CEO of Optimum Energy, LLC. Rothman’s focus on environmental issues, and in

particular the positive impacts of energy efficiency technologies, led him to

found Optimum Energy in 2005. Under Rothman’s leadership, Optimum Energy has

developed a reliable and scalable software solution that is setting a new

standard for heating, ventilating and air conditioning (HVAC) energy efficiency

in the commercial building industry. Today, Rothman’s vision to do good, do well

and prove it is coming true with installations of Optimum Energy’s patented,

Ultra High Performance OptimumHVAC software in commercial buildings across the

U.S.

Rothman’s interest in sustainable building was born out of 20 years as president

of a privately held company that built and managed manufacturing plants for

clients around the world, including locations in Asia Pacific, Europe and the

Middle East. His early commitment to sustainability was evident even then in

that he built those plants to U.S. environmental standards. He is an avid sailor

and founder of the award winning Valiant Yachts company. Rothman is an alumnus

of Northwestern University and Illinois Institute of Technology, and he is a

Certified Business Energy Professional.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]