April 2010

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

April 2010 |

[an error occurred while processing this directive] |

|

|

Jim Sinopoli PE, RCDD, LEED AP |

One of the things everyone is trying to do with their building systems is to extract data from the sub-systems and transform that data into actionable information in order to better manage the building. To most, actionable information means trending the data to observe patterns and exceptions or producing enterprise reports on energy or alarms. What has emerged over the last several years however, are software tools based on fault detection and diagnostics (FDD) that have taken actionable information and system intelligence to a new level. There are now a number of credible companies in the marketplace that have FDD-based tools with case studies of implementations that resulted in optimal system performance, energy savings and improved operations. For those that understand return on investment from commissioning systems and given the normal degradation of the performance of a HVAC system, FDD-based software tools will be a core operational tool. What follows are a description of FDD and some issues in utilizing FDD software tools.

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

OVERVIEW

FDD focuses on HVAC systems. HVAC systems are one of the more complex, sophisticated and energy-consuming systems in a building involving different processes and the interaction of different types of equipment. We measure the performance of an HVAC system in several different ways: indoor air quality, energy consumption and thermal comfort.

FDD is based on research of faults in HVAC systems and the development of hierarchical relationships and rules between the different equipment and processes that make up the HVAC system. For example, a chilled water plant supplying chilled water to air handling units is a relationship; the chilled water plant is the single “source” and the air handling units are multiple “loads”. Another relationship is an air handling unit delivering supply air to terminal units; the air handling unit is the single “source” and the terminal units are the multiple “loads”. In an HVAC system this relationship between “source” and “load” can be via air or water. It is these relationships and the rules within the relationships that are at the core of FDD.

These hierarchical relationships are used to collect fault reports and raw data, and then apply a set of rules. For example, there is a set of rules for systems consisting of a chiller, a boiler, air handling units receiving hot and chilled water from the boiler and chiller, and terminal units receiving supply air from the air handling units. A different set of rules would be applied if there was staged heating and cooling directly at the air handling unit or for single-zone air handling units. There are also different rules for the same equipment based on the state of the equipment; for example a chiller will have a certain set of rules when it is off, another set of rules at start-up and still another during its steady-state.

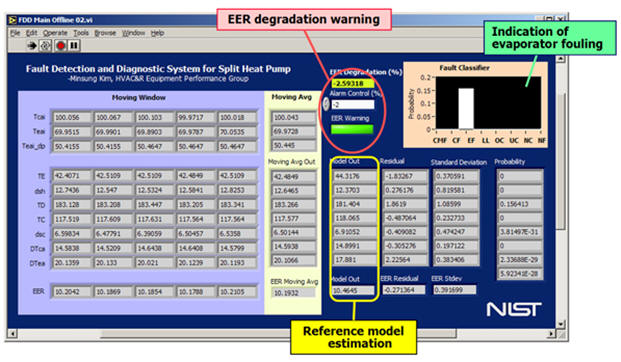

An example from the National Institute of Standards and Technology demonstrates how FDD can be applied. In this case it is FDD developed for residential split-system heat pumps. The US Department of Energy implemented a regulation in 2006 requiring a 30% increase in the minimum seasonal energy efficiency ratio (SEER) for central air conditioners. Equipment manufacturers made the improvements to their equipment and at the same time NIST’s HVAC&R Equipment Performance Group developed a FDD approach for residential heat pumps to assess and assure the improvements in the equipment. NIST identified six common faults in the equipment: improper refrigerant charge, improper indoor airflow, incorrect outdoor airflow, flow restriction in the refrigerant liquid line, non-condensable gases in the refrigerant and reversing valve or compressor valve refrigerant leakage/bypassing. They took a look at fault-free and faulty performance characteristics for both heating and cooling modes. The research will result in a set of FDD rules that will be used in commissioning and the detection of sensor failure for residential split-system heat pumps.

ISSUES AND CONCERNS IN IMPLEMENTING FDD

Lack of Understanding – Owners who have spent small fortunes on DDC and BAS systems may think their HVAC equipment is running optimally or they may have so many alarms or issues with their core system they cannot understand how FDD will help. In the simplest of terms FDD rules are applied automatically within the threshold of parameters of the DDC sequences of operation. A VAV air handler can be delivering 55 degree supply air to the zones and there is no alarm condition in the DDC system. But if the cooling coil valve is 100% open to produce the 55 degree air, the FDD rules set would generate a fault indicating there is a problem that needs investigating and resolution based on proper cooling load design perimeters.

Lack of Data - FDD needs data from the BAS systems. If there are not enough sensors, if the sensors are inaccurate, or if the building has a legacy control system, there can be issues with obtaining the data required.

Rules Specific To Building Systems – The rules apply to specific HVAC relationships and equipment, and building owners need to be assured that their specific building systems are addressed by the FDD software application or can be developed. Many FDD software products start with FDD rules developed by NIST that are then added to with rules developed by others or by the companies themselves.

How to Handle the FDD Information – Facility Management organizations need to decide how best to handle the FDD information. If every fault is treated as an alarm, FDD could add to a workload for technicians and engineers that already feel overloaded. However, if you set the faults aside and study the remedies and manually prioritize the faults, there could be a sense that you’re not responding to a known fault as quickly as you should.

[an error occurred while processing this directive] Using the Diagnostic Data – Many of the FDD-based software tools can provide information to the technician or engineer regarding potential corrective actions. This information needs to be integrated into the work order system, which may be one application in a whole suite of facility management applications, in order to effectively utilize the information.

Prognostics Data - While FDD seems inherently capable of providing prognostic data, that is it can analyze fault conditions or degradation faults and predict when a component will fail or not be able to perform accurately, very little has been developed in this area. In addition, prognostic data would allow for more proactive condition-based maintenance which may be a different approach for any facility management organization that is reactive and corrective.

Lack Of Applications For Emerging Systems – FDD routines do not currently address newer on-site energy sources such as solar, wind or geothermal, or touch on power management or demand response.

SaaS – Most of the

current offerings are provided as Software as a Service (SaaS). This can be an

issue with many corporate IT departments because of the need to pierce the IT

firewalls and security. However, some facility management organizations see it

as an advantage because it means less involvement and dependency on the IT

department.

Alternative Ways to Deploy FDD - At some point in

the future control manufacturers will integrate FDD routines into their

controllers, starting with the large equipment such as chillers.

Keeping such a significant energy consuming system such as the HVAC running at optimal performance is challenging. Many times failures or sub-optimal performance goes unnoticed for long periods of time. Case studies from companies vending FDD-based software services can show energy savings in the 10% to 15% range with the capability to correctly identify faults and the primary response 95% of the time.

Software based on FDD is really a new class of tools

for building owners, providing them almost real-time analysis and diagnostics of

their HVAC system and really adding some “smarts” to a smart building. It’s not

difficult to imagine similar tools for other building systems and the potential

for enhanced intelligence built into tools for facility management.

For more information about smart buildings, technology design or to schedule a

Continuing Education program, email me at

jsinopoli@smart-buildings.com.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]