Getting the Most out of Your Building Automation System

|

April 2012 |

[an error occurred while processing this directive] |

|

Continuous Optimization

Getting the Most out of Your Building Automation System |

|

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

Let’s

say you have a well managed, well maintained, relatively efficient

building. Someone offers you the chance to reduce your energy use by at

least 10%, improve tenant comfort, and install new controls features -

all with a payback of 2 to 3 years. Intrigued? Skeptical? These

are the results for more than 50 of SES Consulting’s Continuous Optimization clients this year.

Why Continuous?

Anyone with experience in building automation knows that, from time to

time, your system needs a tune up. Building performance declines over

time and, as a consequence, energy use increases. Poor performance can

be the result of deficiencies in the original commissioning, broken or

miscalibrated sensors, conflicting set points, or manually overridden

equipment to name a few common problems.

The standard response to these issues is to embark on a

retro-commissioning (RCx) of building systems; identifying and fixing

all the issues that have arisen over time. Although RCx can be very

effective at reducing energy consumption in a building, the persistence

of savings can be poor. In a few years you’re likely to find many of

the same problems and poor performance that existed before. Breaking

out of this cycle is the motivation for Continuous Optimization.

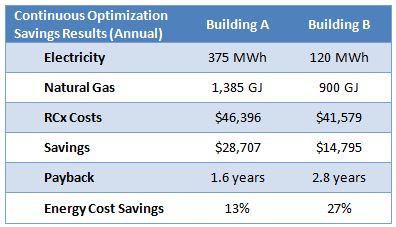

Continuous Optimization addresses the shortfalls in the RCx process by

incorporating real time feedback on building performance that alerts

staff when building performance starts to slip. Enabling your

operations team to identify and correct the problem when it occurs and

maintain optimal building operation. The following table shows the

results of two recent Continuous Optimization projects

in British Columbia.

Although the savings and payback are impressive, more important is the

fact that more than a year later these savings are being maintained

and even improved on, using a Continuous Optimization approach.

Finding the Savings – The Responsive Building

Beyond the energy savings from returning systems to their original

operating condition, there are often extensive opportunities to improve

operations efficiency when compared with the original design.

Installing new controls technologies or using strategies that weren’t

available or cost effective at the time of the original build, can lead

to even greater savings. The rapid development of new controls

technology combined with falling prices for many of these items has

made these controls accessible for a relatively small investment. The

table below shows a sampling of some common measures that can be

implemented as part of a Continuous Optimization process.

Typical Control System Enhancements

The common purpose of these measures is to allow the building to

respond better to variable loads. The environment in which a building

operates is always changing; people come and go, weather changes and

daylight levels go up and down. Older buildings tend to maintain their

systems operating at constant loads usually designed for maximum

occupancy, unable to take advantage of the changing loads to make the

building more responsive, comfortable, and save energy. With the

addition of new control strategies and devices such as variable speed

drives and sensors to measure air quality or detect occupancy, we can

use the existing BAS infrastructure to respond and meet changing

conditions, significantly reducing the energy footprint of the

building.

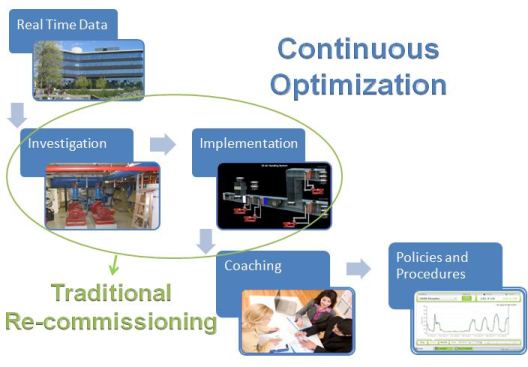

The Continuous Optimization Process

Continuous Optimization starts with collecting real time data on the

building operations. This information can be collected using the

building’s BAS or by software monitoring real time energy consumption.

This software, often cloud based, is known as an Energy Management

Information System or EMIS. The real-time data is used to better

understand the operation of the building so that a performance baseline

can be established. The baseline is then used to verify the energy

savings once the building has been optimized.

During investigation, the energy conservation opportunities and

operational deficiencies are identified from a combination of on-site

investigation and review of the BAS and EMIS. Real-time energy

data can reveal important information about the building that is not

obvious from monthly energy bills. As an example, high overnight

base loads or unusual demand spikes, readily visible in real-time data,

may indicate load scheduling and demand shifting opportunities. Once

the opportunities are identified, a list of potential measures is

developed, and the most cost effective or desirable of these are then

selected for implementation. The measures are implemented by a team

including the consultant, contractors, and building operations staff.

During implementation the EMIS provides valuable feedback on the

effectiveness of each measure, allowing your team to make adjustments

and ensure the maximum energy savings potential is achieved.

Maintaining those hard earned energy savings is the heart of what

differentiates Continuous Optimization from a standard RCx approach.

This is often the component that presents the greatest challenge for

many facilities. One or two set point changes that go unnoticed can

dramatically erode energy savings. Training your operations staff to

understand the measures implemented, identify when they have varied

from optimal, and respond to these exceptions in real-time is critical.

In the past, most building operations staffs have been focused on

keeping people comfortable. With a Continuous Optimization program,

they are also the ones with the best opportunity to maintain energy

savings. We’ve found the following tools and supports are crucial

for success in this undertaking:

[an error occurred while processing this directive]

Saving energy doesn’t have to end at the mechanical room. Many of the

Continuous Optimization tools can also allow you to communicate this

success to the building occupants and administration. Energy display

dashboards in public areas or allowing web access to a virtual

dashboard can be a great way to gain the support of building occupants.

Real-time feedback on staff-led initiatives such as turning down the

temperature or turning off lights has proven to be an asset in

motivating occupants. People are much more willing to go the extra mile

when they know that their actions are making a difference.

Going Beyond – The Future of Continuous Optimization

The measures and projects described above can largely be accomplished using 15 year old BAS technology. However, BAS are currently undergoing a rapid evolution incorporating more modern technology and harnessing the power of the web and cloud. The BAS is no longer just a tool to operate mechanical equipment, but a system that gathers information from numerous sources (temperature, weather, air quality, energy use, occupancy sensors, light levels, etc) and uses this information to operate the building in the most efficient manner possible. With more advanced capabilities, BAS technology is becoming increasingly integrated, sharing data between formerly disparate systems such as HVAC, security and lighting. This allows the system to make better decisions, avoid duplication of equipment and automate more of a building's operations. Most if not all of these advanced features can be justified in the name of energy efficiency, improved comfort, or better maintenance.

Modern BAS systems are creating new information streams like analytics

or fault detection and diagnostics (FDD). Analytics expands on the EMIS

described earlier; using information mined from the BAS to

automatically alert staff to abnormal or unusual equipment behavior

caused by broken valves, sensors out of calibration, failed

controllers, etc, before they cause problems. This can greatly speed up

the process of identifying and diagnosing operational problems,

improving maintenance of various building systems, and preventing

catastrophic failures.

The web based nature of the modern BAS also makes it easy to broadcast

building related information to occupants. Below is an example of a

dashboard display that combines live energy consumption data with data

feeds from elsewhere on the web, in this case showing sports and

weather information to draw more traffic.

Occupant Information Dashboard (Courtesy of ESC Automation)

Intelligent buildings allow us to go further than ever before in

achieving improved efficiency and performance in a practical and cost

effective manner. Below are just some of the advanced energy savings

features being implemented in several SES Consulting

projects.

Advanced Control System Enhancements

An advanced, integrated, BAS allows you to turn off ALL lights and

non-critical plug loads in a building when the security system or space

occupancy sensors indicate the building is empty. Intelligent

occupancy sensors and advanced algorithms can not only tell you if

someone is present, but how many people, and automatically adjust the

lighting and HVAC system appropriately. SES has used this strategy with

great success in intermittently used spaces such as university lecture

theaters to avoid bringing on all of the lights and HVAC systems if the

space is only being used by one student. These represent a small

sampling of the opportunities to customize advanced control systems to

meet the unique needs of your facility.

Taken together, these features make it possible to operate buildings

smarter and more efficiently, making a powerful business case to

upgrade to a modern, state of the art, control system. More

importantly, the web enabled interfaces and cloud based services

facilitate the sharing of key performance information throughout your

organization, from occupants, to operations, to executives at the

enterprise level.

The opportunities to automate and improve building operations will continue to grow and evolve. Continuous optimization, whether you have a 15 year-old BAS or a fully integrated modern system, will allow you to take full advantage of these systems, achieving and maintaining optimal building operations throughout the life of your building.

About the Author

Brad

White, P.Eng, MASc, Principal - Brad has four years of experience

working with energy systems as a researcher and mechanical engineer.

His work has focused on seeking ways to improve the sustainable use of

energy through conservation and improved efficiency. Prior to joining

SES Consulting Inc., Brad helped develop new manufacturing techniques

for clean energy technologies as a master’s student and research

engineer at UBC.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]