|

April 2020

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

Removing

the Umbilical Cord between Controllers and Sensors

This is only possible by

removing the

logic from the logic controllers and putting it into standard software

running on edge computing. And that is only possible by removing the

umbilical cord between controllers and sensors, the wires that restrict

them from taking more and better inputs.

|

Phillip

Kopp CEO

Conectric Networks

Part 2 of 2

Part

1 0f 2

|

In

the first part of our flexible building mini-series, we

explored how wireless digital control is the core to establishing

operational flexibility over a building's lifecycle, and why this leads

to a more comfortable, efficient and functional building environment.

Today we look at the formula for a truly open, low cost and future

proof building.

The next order of building flexibility is to remove the specialized programming tools and compilers that

exist in today’s digital PLC’s which lock your building into a state of

inflexibility. Instead, we look at a roadmap for buildings with control

sequences programmed in standard software languages like JavaScript or

.Net using open tools and completely separating hardware from software.

Why are controls sequences compiled with

proprietary tools into logic controllers in the first place?

Technically speaking, direct digital controllers (DDC) and PLC’s do not

have very powerful onboard computers. They run on the firmware that has

to be programmed to each controller individually. A static program that

can’t be changed once is “flashed” into the hardware. If you want to

change the control sequence or add a new sensor, you have to reprogram

the firmware in a specialty software with line drawings to reflect the

changes in each controller. That software will only compile and run on

the chip that is specific to that controller and thus, the only way to

program it is using the specialized tool for that vendor. While this

may be fine for operational day one, it has many adverse effects after

that. Including limiting the number of people that can work on

that building in the future, to those that have the right programming

software, those trained to use that software, and a high cost to change

sequences or add sensors—making the building very inflexible. There are

solutions to this, such as the use of the Sedona

framework; however, these are mostly band-aids, layered on top of

existing proprietary controls and don’t get to the root of the problem.

These are special programs limited to building automation, meaning

there is a small labor pool to work on these controllers and limited

transferable skills between building automation and other industries.

Let's

look at a real-world example. Something as simple as adding occupancy

sensors to existing office building HVAC systems will have a dramatic

impact on energy efficiency. Yet, it cannot be done to existing HVAC

systems because that would require wiring sensors to controllers and

reprogramming controllers individually. Running wire will be very

expensive. Few contractors (i.e. those affiliated with the controller

vendor) have access to the software or know how to use it. This limited

resource (in many cases territorial, meaning there is only one per

city) creates a monopolistic business environment. Again, driving costs

to the point where ROI is unachievable. Yet, this is the precise reason

why the current design remains; the system is to protect monopolistic

and territorial business practices, which is bad for buildings, owners,

operators, occupants and even our environment. The advent of open

protocols and projects like BACnet or Haystack will not change this

scenario as long as controllers must be programmed with compiled

software on proprietary programming toolchains, using specialized

vendor software that only they control and train people how to use.

Under the current system, the cost of the upgrade will easily outweigh

ROI, and we see the result, most buildings are 50% inefficient or even

more.

Take the control sequences out of the

controllers and into more powerful edge servers that run software that

can be worked on and developed in standard languages opening the door

for a vast resource pool to work on building automation, the entire

global software developer community! Imagine what having access to the

global software developer brain trust and market competition would do

not only for the quality of the control algorithms but to the cost of

developing and implementing them?

A good

comparison might be the early days of the internet when you had to pay

a website developer $10,000's or $100,000's to create each custom

website individually. A costly and time-consuming exercise with a

limited number of specialized resources, much like the BAS controller

programming of today. Fast forward about 15 years, and platforms like

Wordpress standardize beautiful and functional template-based websites

on the order of $100's of dollars, maybe 10% of the initial cost, or

Wix that allows you to build your site for free.

A website

like this would have cost $100,000's to develop in 2008, but maybe just

$100's today.

Why hasn't this happened in building automation

yet? There are a plethora of low cost, reliable, "dumb" i/o controllers

on the market that follow instructions provided by a server. SCADA

systems typically are designed in industrial factories. So why not in

buildings? It is not due to a lack of available hardware.

The answer is not just poor business practices,

but partly also a technical one. Wireless technology finally permits

removing the umbilical cord between controllers and sensors, the wires

that restrict them from taking more and better inputs. The reason why

logic must exist in the controller today (making it exceedingly

difficult to change and adapt in the future) is because the inputs are

attached to them. If you remove the inputs from the controller and you

run everything through software, there become zero reasons for

programming logic into controllers, and the building is free from

inflexibility! Wireless sensor inputs placed where needed and updated

as building use and tenant improvements change over time. Those inputs

feed into the smart software that operates advanced control sequences,

intelligent algorithms and even artificial intelligence applications

that can be worked on by standard software developers over the life of

the building. Wireless technology makes it possible to use common and

open languages like Node JavaScript developer kits. Provided license

free by companies like real-time mesh wireless technology provider Conectric Networks, and combined with open source

frameworks like Node-RED

enables a completely free and open building control platform taking

buildings into the modern software age of Wordpress and Wix

(disclaimer, I am the co-founder and CEO of Conectric Networks).

With wireless

networks, "dumb" slave controllers, programming control sequences in a

completely 100% digital environment using standardized software

languages with tools that any software engineer on the planet has

access to and knows how to use, we can completely revolutionize how our

buildings work. They will be fully programmable, flexible, efficient,

adaptive and then plugged into infinite ecosystems of new software,

tools, energy systems, human interfaces, smart algorithms and even

artificial intelligence (AI) programs. We can connect brains to

buildings. More importantly, they will be easy to service and maintain

over time, having not only a far lower cost to build, but also to

operate. The ROI is virtually infinite when comparing to the existing

wired approach today.

The final question remains. If it were so easy,

why isn't everyone just doing it? Putting all else aside, there are

always tradeoffs. This is as true with technology as it is with

engineering, business practices and even social balance. There

have been dramatic improvements in wireless technology; the truth is

that high throughput and high bandwidth communications like what we

have described, such as WiFi or Cellular require a lot of power to keep

a constant connection, or only transmit short distances and therefore

also require wires… sort of defeating the whole purpose of the

conversation.

Existing WiFi networks are short-range, power-hungry and demanding to manage securely.

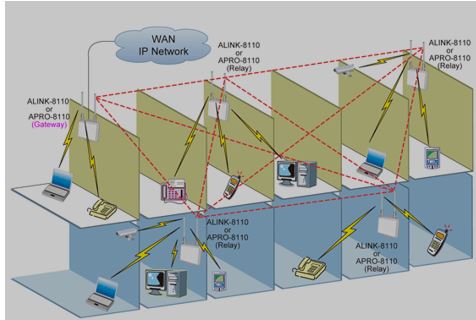

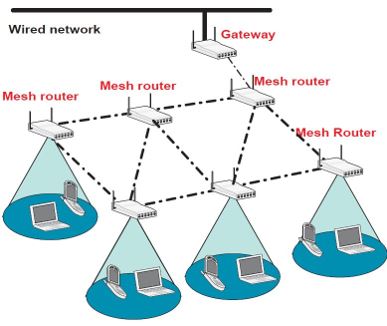

Advanced

mesh networks allow real-time battery operated devices.

Wireless technologies that don't require wires

and can run on batteries or energy harvesting communicate infrequently

and unreliably, making them perform poorly for the kind of expectations

we have for latency and operation in building systems. Compared to

this, wired systems just work better. Fortunately, there are companies

like our company Conectric Networks, working on what I call "hybrid

mesh systems." Hybrid mesh systems leverage both constant powered and

battery-powered nodes to provide the performance of wired networks,

with the flexibility of wireless ones and enable the Jetsons building

of the future. Thanks to editorial platforms like automatedbuildings.com

giving myself and others from companies like Lynxspring, EnOcean, LoRa

Alliance, Aruba Networks the opportunity to write articles like this,

we can share our work and the great promise it brings to solving the

inflexible building challenge.

About

the Author

Phillip Kopp is a technology co-founder who fell

into the world of building automation and energy efficiency over 20

years ago starting the first totally wireless RF sensor company for

hotel guestroom automation, sold to the Somfy Group in 2009. He has

since built or sold three other companies in financial technology and

SaaS and has contributed to over 15 US Patents. Phillip is currently

the CEO of Conectric Networks, whose goal is to install billions of wireless

sensors into buildings, AI enabling to develop a massive virtual grid.

Reducing 20% of global energy consumption and paving the way to a

safer, more productive and healthier future.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]