Analytics do not have to be complicated to deliver valuable, actionable results that save facility operators real dollars.

|

August 2011 |

[an error occurred while processing this directive] |

|

“Would you run your business without financial analysis

tools?” Analytics do not have to be complicated to deliver valuable, actionable results that save facility operators real dollars. |

|

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

Would

you, could you, operate a successful business without the ability to

track revenue against costs, performance of business units,

productivity of salespeople, return on investment of new initiatives?

Would you manufacture a product without looking at the costs of its

components and opportunities to reduce those costs?

It pretty clear none of us would do that if we wanted to stay employed

and have a successful business. Yet in many cases these fundamental

techniques are not effectively used to manage the costs associated with

the operation of our facilities.

Buildings consume 30% of the total world energy consumption and we

routinely accept their energy costs without knowing where those costs

go and whether they could be reduced.

With the huge volume of data that

modern building automation systems

and equipment systems produce we “should” know everything about the

operation of our facilities. Interestingly, however, too much data

looks surprisingly like no data at all. If I can’t find essential

information then I might as well not have it.

This isn’t a new problem for business, however. Financial managers long

ago learned the necessity of using software to assist in managing and

analyzing the vast quantities of data produced by business operations.

Business intelligence and analytics software automatically identifies

important trends, issues and potential problems, bringing them to the

attention of busy managers who can then take necessary action.

[an error occurred while processing this directive]Today,

specialized analytics tools are being applied to analyze the

operation of equipment systems, energy consumption and costs, and

facility operations activities as a whole. The result is the ability to

move to data driven management of our building equipment systems and

physical assets.

Where does analytics fit in delivering tangible business value to an

organization?

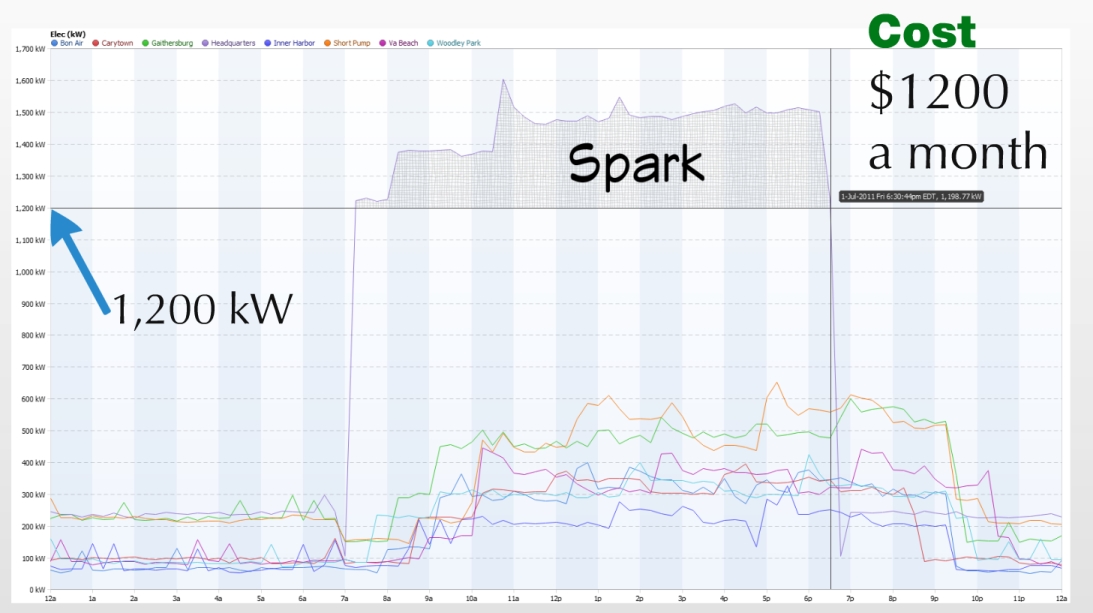

An example in energy management –

Automatically identifying deviation from baseline energy consumption

Establishing a desired baseline or target for energy consumption is a

key part of most energy efficiency projects, whether it is a lighting

retrofit or replacement of HVAC equipment. We expect the project to

result in a new lower energy consumption profile for the facility. This

target is typically expressed as a design baseline. An important part

of verifying the results of such a project is to track actual

performance against this baseline. This can be done manually, but what

if you had the ability to automatically compare energy consumption

after the project against that desired operating baseline and be

informed of all of the periods of time when electrical demand (or

consumption) went above the baseline by more than 3% (or any amount of

your choosing).

An analytics system can do this for you. It will find periods of time

that deviate from desired operation and automatically inform you of the

issue, delivering a clear, understandable display showing just when and

where deviations have been found. No hunting for data – the system can

tell you that the condition has been found. A simple mouse click takes

you to a detailed view of the issue, the time of occurrence, the

duration and which sites or meters were found to be deviating from the

desired baseline, and, the actual cost of those deviations.

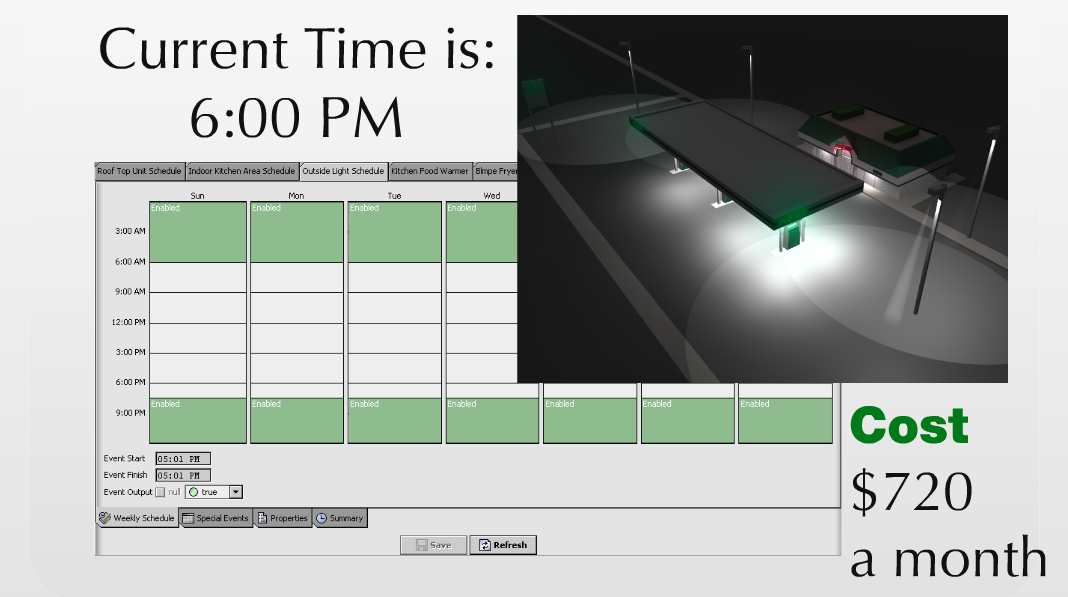

Example of Equipment Operation: How

frequently and how long do buildings run in emergency override?

Exceptions happen. Building systems need to be put into emergency

override mode for a variety of reasons. But how long do they stay

overridden and how much does it cost?

The Solution – A rule or algorithm can automatically track the number of hours that sites are in override mode. A report then provides managers with a clear view of the number of hours of override operation by site and across the portfolio. The impact can be significant.

The

Result – Actionable information that can be used to drive

reductions in energy costs.

These are two simple but real

examples, which brings out another key

point – analytics do not have to be complicated to deliver valuable,

actionable results that save facility operators real dollars.

As they say, information is power. In facility management actionable

information produced by a new generation of analytic software is the

key to lower energy and operating costs and better building performance.

About the Author

John Petze, C.E.M., is a partner in SkyFoundry, the developers of SkySpark™, an analytics platform for building, energy and equipment data. John has over 25 years of experience in building automation, energy management and M2M, having served in senior level positions for manufacturers of hardware and software products including Andover Controls, Tridium, and Cisco Systems. At SkyFoundry he rejoins Brian Frank, co-founder and chief architect of Tridium’s Niagara Framework, as they look to bring the next generation of information analytics to the “Internet of Things”.

[an error occurred while processing this directive] [Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]

[Click Banner To Learn More]