|

August 2022 |

[an error occurred while processing this directive] |

| |

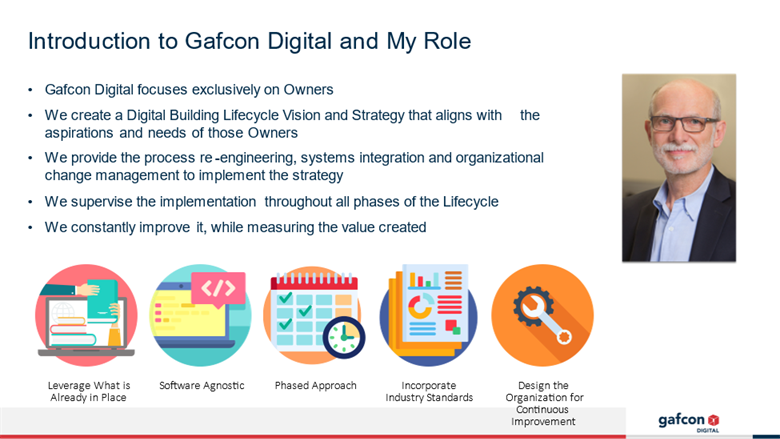

INTERVIEW – John Turner

John joined Gafcon in 2012 as he wanted to apply evolving construction technology to benefit owners. He built up a stand-alone business unit which was spun out as Gafcon Digital, Inc in April 2022. He has been instrumental in the convergence of multiple siloed technologies and building a team of Architects, Civil Engineers, Technologists, Data Scientists and Project Execution Specialists that all want to transform the digital building lifecycle, but from the perspective of an Owner. He has applied and continually develops this through engagement with multiple multi-billion dollar building lifecycle programs for Serial Builders.

[an error occurred while processing this directive]

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Links |

| Software |

| [an error occurred while processing this directive] |

Sinclair; John, you are the CEO of Gafcon Digital

Inc. Please introduce yourself and the

company.

Sinclair; You describe Gafcon Digital as a Digital

Twin Systems Integrator. Why are your

services needed?

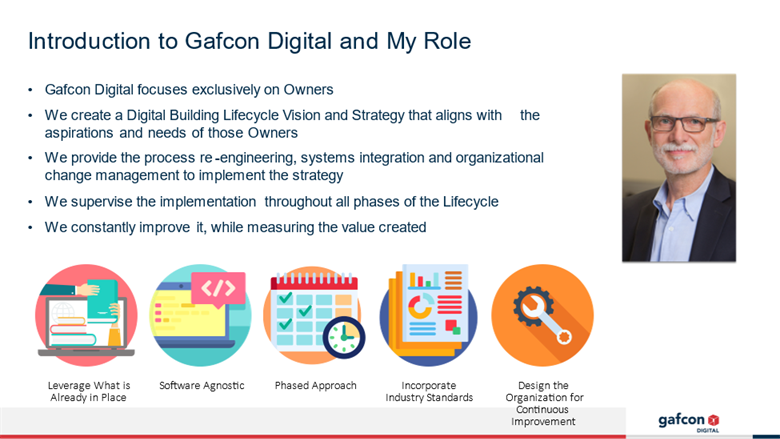

Digital Twins are a new concept for the

Owners and Operators, the serial builders, of the built environment. Digital Twins are on every owner’s

agenda. We have supported some of the

most advanced applications of Digital Twins and so have unique experience and

expertise that can assist Owners attain their goals. Few understand what Digital Twins really are

and the value that they can unlock. Our

first task is to explain the What, the Why and the How of Digital Twins.

I would first of all like to explain what a

Digital Twin is not! It is not a virtual

representation of a physical building.

It is not a BIM or a representation captured by reality capture. The vast majority of vendors are selling

digital twins without understanding some core components. Let me address those.

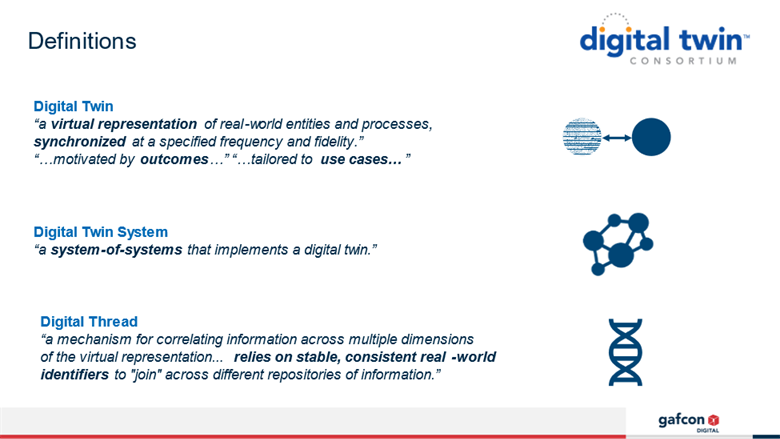

The traditional view of a digital twin is

that it has three components: The

physical, the virtual and the link between them. We add two additional components. The first is the use case. The digital twin must create value for the

owner and without a defined use case the digital twin approach cannot be

aligned to deliver that value. The

second is the digital thread. It is unlikely that there will be a single

digital twin in the digital building lifecycle. If the digital twin is aligned with the use

case and it starts in planning then the data collected will be aligned with

planning and not operations, however the data structure is relevant and the downstream

digital twins will be reliant on the data created upstream and so all must be

connected using a digital thread. Support for the lifecycle hence requires

multiple digital twins and a system of systems approach.

I use the analogy of a smart phone to

explain what we do. We integrate

systems, processes and data into the digital thread which is analogous to the

smart phone. Once the functionality and

associated data has been aggregated and correlated, just like on a smart phone,

value can be created by building applications on that smart phone platform far

more effectively than developing separate siloed applications. There are three main things that prevent this

approach:

·

The first is that the digital

building lifecycle is siloed or fragmented.

Planning does not communicate with Design. Design does not communicate with

Construction. Construction with

Operations etc. There is a need for a

data standard and process reengineering to enable that communication.

·

The second is that there is no

single software vendor that can provide everything necessary to support a

digital twin across the complete lifecycle.

Software vendors are aligned with the existing silos and have no interest

in cooperating with their competitors.

There is a need to think end to end across the whole lifecycle rather

than within these silos.

·

The third is that the industry

has a project mentality. Our

conventional processes focus on the need to bring in the project within budget

and schedule but very rarely does an owner question the format and approach to

that budget and schedule. Part of this

is because of the cost and length of a project.

If we were manufacturing widgets on an hourly basis we would want to

optimize the approach and we would have the data and analysis to do that. Our focus on serial builders and owner

operators brings us closer to that manufacturing perspective so that we can

focus on the process as well as the content of a project.

Sinclair; Why should an Owner be interested in

this approach?

I will sum it up in one word –

predictability. Predictability covers

many areas: Cost, Schedule, Safety,

Quality as well as sustainability, employee productivity, carbon footprint,

competitiveness etc.

Sinclair; So how do you advise Owners to start the

journey?

We summarize our approach into three

phases: Communicate, Collaborate and

Correlate.

In practice it is more complex and the

overall transformation is generally delivered by a Program Management Office

focused on People, Process and Technology.

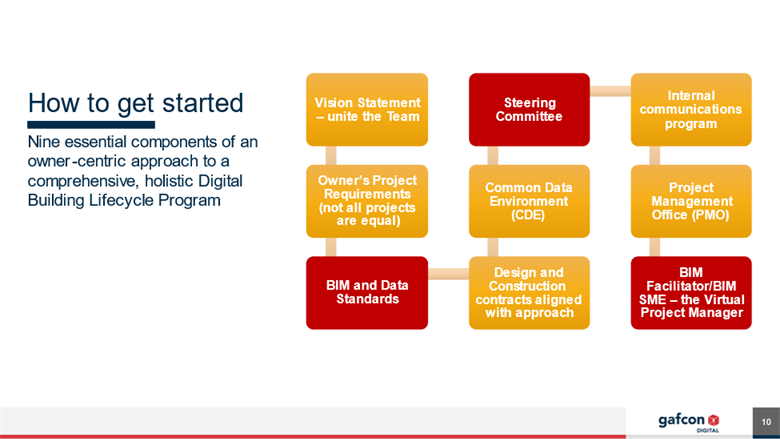

We believe that there are nine critical elements in this approach but

the most important are:

·

The necessity to introduce BIM

and data standards that will support the complete digital building lifecycle.

·

The need to establish a

steering committee that can address the integration of the silos.

·

The focus on the virtual as

well as the physical. Most owners would

not even consider delivering a project without an owner project or construction

manager for the physical building. We

believe that there is a need to do this for the virtual building.

I would like to emphasize the Correlate

phase. This allows us to align the

performing twin with the simulated twin and so perform closed loop analysis to

further improve the performance of the built asset. The digital twin hence moves from largely

reactive, in that it provides the data on how a building is performing though a

series of Internet of Things or Internet of Activity sensors, into being

proactive. This is of particular benefit

in evaluating energy conservation measures and tracking the carbon footprint of

a building.

Sinclair; How do you address the differing

requirements of the stakeholder groups that cover the complete lifecycle?

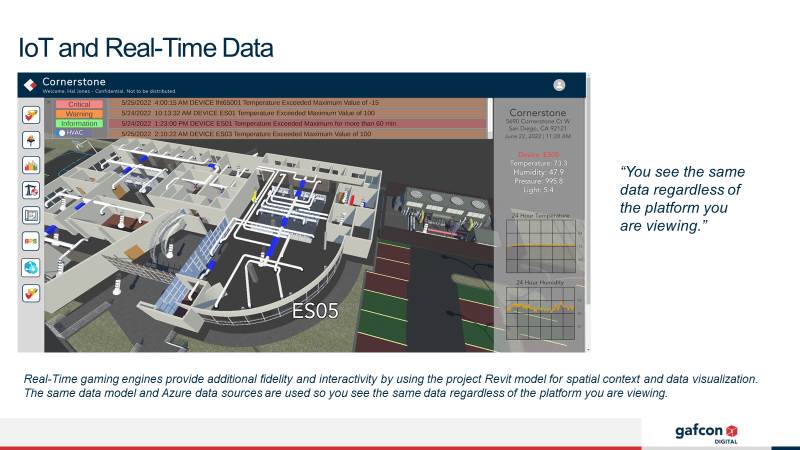

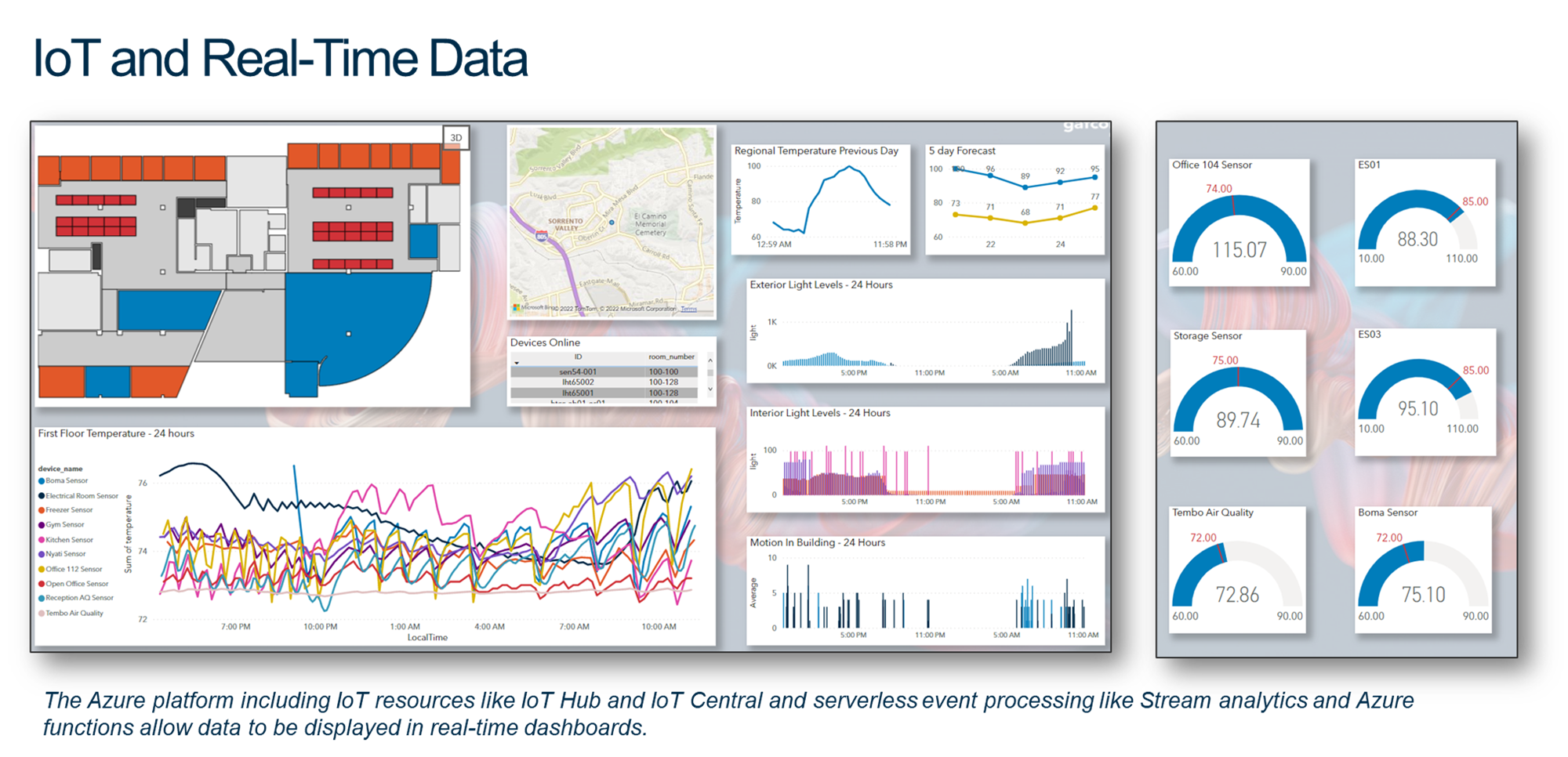

That is a very important question. The system that is used to interface with the

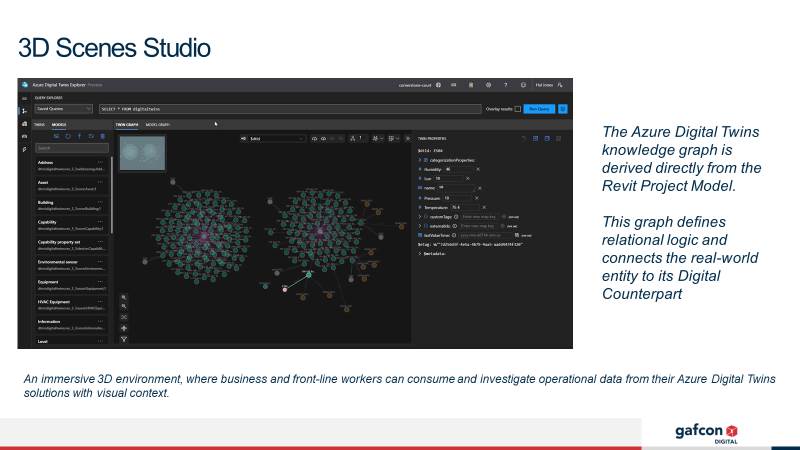

digital twin will be different for each stakeholder group. While BIM and Reality Capture approaches are

important for the design and construction phases of both new and existing

buildings, they are not optimized for operations and maintenance. Going back to our smart phone analogy the same

data can be used in many different applications which are aligned with many

different users. Our approach allows the

selection of the best user interface for the user. This may be graphic such as a real time or

gaming engine, of a dashboard like Power BI, or it may be a GIS or BIM

system. Our approach allows all the

required data to be available through the user interface that is most familiar

to the user. Several graphic approaches have been illustrated. All use the same data.

Sinclair; What final advice do you have for our

readers?

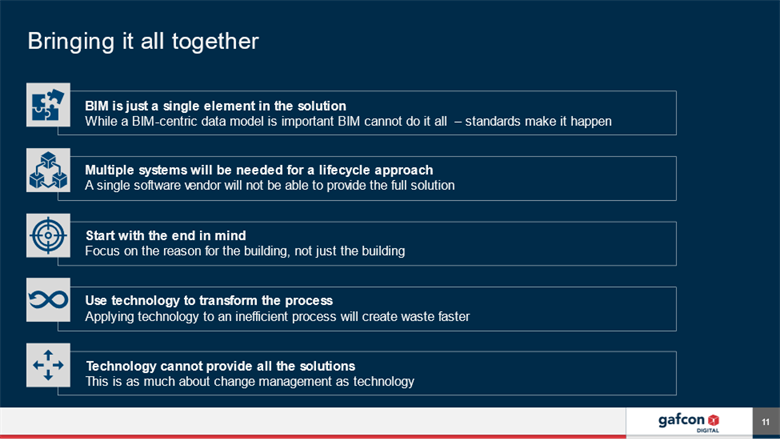

Implementing a digital twin approach to the

digital building lifecycle is not just about technology. Start with standards, focus on value and

demonstrate that this can be created with a proof of concept that can be

quickly piloted. And be prepared for the

people, process and organizational changes that will be required as this is a

transformational approach, not just an incremental improvement to the existing

process.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]