December 2007

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

December 2007 |

[an error occurred while processing this directive] |

|

|

Ken Sinclair,

AutomatedBuildings.com As published |

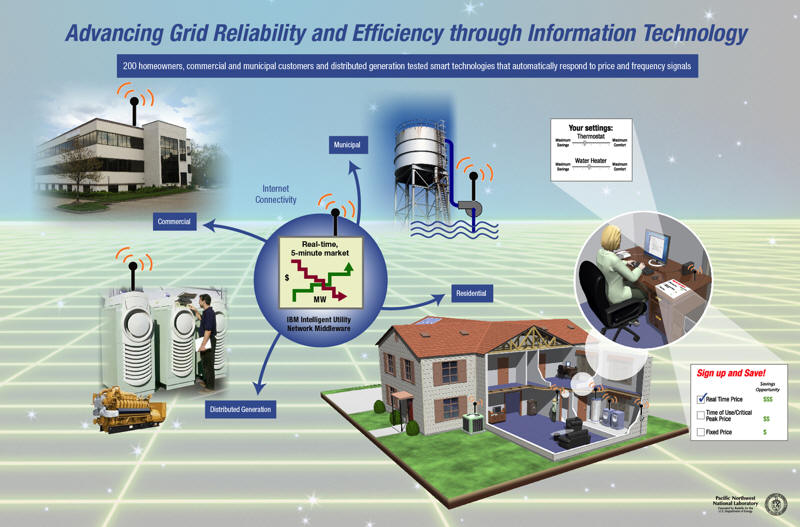

What is GridWise? It is an entirely new way to think about how we generate, distribute and use energy. Using advanced communications and up-to-date information technology, GridWise improves coordination between supply and demand, and enables a smarter, more efficient, secure and reliable electric power system. Since the refrigeration industry controls the energy-intensive part of the air conditioning, food and industrial cooling industries, it is mandatory that this partnership be well understood to allow correct integration and interoperability with the grid.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

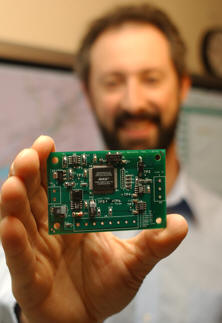

The Grid Friendly appliance turns normal household appliances into ones that would better regulate energy usage and help prevent local and national blackouts. |

How can we help make the refrigeration industry “FrigWise?” Make all refrigeration equipment interact with the smart or GridWise electrical grid in a “grid-friendly” manner. The wisdom and economics of buying back peak electrical demand is now being driven by the exposed real costs of new electrical generation and distribution. This provides new money to the refrigeration industry to reduce overall electrical peaks in an orchestrated interaction with the grid allowing us to be FrigWise.

GridWeek

In April 2007, GridWeek demonstrated the winds of change are blowing in

several directions and at several levels. The event allowed politicians,

electrical regulators, generation, distribution folks, technology providers and

electrical energy users a common venue to talk about the smart grid of the

future and its required changes. It showed how connectivity and innovation will

help change the grid users’ behavior by communicating price breaks for

time-of-day billing using new connectivity paths.

Buying back peak electrical demand is big business. A $900 billion market opportunity was identified for the industry to make the national grid smart and wise with interactive connectivity. GridWise Demand Response (DR) and GridWise devices provide a quicker response time than existing generation control. These quick interactions when coupled with the shear economics of not providing new generation and distribution is the reason that the grid folks are willing to invest in the refrigeration industry interaction with the grid. Conservation and DR coupled with smart grid approaches are being billed as the new green fuel for the electrical grid.

The critical shortage of electricity in the United States is driving utilities and regional Independent System Organizations (ISOs) to offer significant incentives on electricity loads that can be curtailed at peak times. Issues driving the need and opportunity of DR include: spiraling energy costs; shortage of electric generation at peak periods; demand for energy efficient green buildings; increased awareness for reducing the carbon footprint; and availability of communication and control technologies.

At GridWeek, John J. “Jack” McGowan, CEM Energy Control Inc. GridWise Architecture Council Chairman said with GridWise, IT interoperability will lead to DR as a basic curtailment—turning electric loads off—program, but then to expand a truly intelligent building functionality that reshapes the load curve by leveraging automation.

[an error occurred while processing this directive]

Who turned off the lights?

Power outages cost U.S. business at least $50 billion a year, according to

Electric Power Research Institute estimates. When given the opportunity to

prevent the electrical grid from going down or dropping to a lower level of

electrical use, many see it as a “no brainer.” Computer screens going black,

servers down, critical lighting going off, and loss of other essential services

such as refrigeration strikes fear into people. The organized start-up of

refrigeration systems after a power outage has great value not only to the smart

grid, but to the refrigeration equipment itself.

Having the technology to shut down refrigeration equipment when the electric cycle sags and or a low voltage presents a danger to equipment is a mutual benefit of GridWise thinking. Imagine FrigWise devices that could shut off before the low voltage and rapid number of starts caused by grid problems could damage equipment. These devices can provide the necessary intelligence for equipment to achieve this interaction goal.

The Grid Friendly appliance controller

A coin-sized integrated circuit developed by researchers at Pacific

Northwest National Laboratory may help solve the nation's overworked electricity

grid. Called The Grid Friendly Appliance Controller, the circuit board turns

normal household appliances into ones that would better regulate energy usage

and help prevent local and national blackouts.

The controller developed senses grid conditions by monitoring the frequency of the system and provides automatic demand response in times of disruption. Within the North American power grid a disturbance of 60-Hz frequency is an indicator of serious imbalance between supply and demand that, if unarrested, leads to a blackout. This simple computer chip can be installed in household appliances and turn them off for a few minutes or even a few seconds to allow the grid to stabilize. The controllers can be programmed to autonomously react in fractions of a second when a disturbance is detected, whereas power plants take minutes to come up to speed. They can even be programmed to delay restart instead of all coming on at once after a power outage to ease power restoration.

Its advantages include:

• More reliable power grids are less costly to run;

• Smaller electricity bills for consumers;

• More efficient power plant use;

• Inexpensive; and

• A foundation for future grid management.

By integrating the controllers with appliances at the factory, costs can be reduced to a few dollars per appliance and customers will not even notice the short interruption. Turning the compressor off, but leaving the light on in a refrigerator is an example.

When a communication system becomes available beyond the power grid, the "smarts" for this system are already on board the appliances to do much more sophisticated negotiation and control, such as reducing peak loads. This simple, cost-effective technology becomes an island of new technology from which ever-more sophisticated aspects of GridWise can grow.

With the GridWise concept information technologies can help balance supply and demand to better manage the electric grid. |

Grid Friendly refrigerators

Computer and Internet technology has become increasingly commonplace, to the

point that its coming application to “smart” household appliances is being

discussed in the popular press. A Grid Friendly refrigerator is a refrigerator,

freezer or a combination appliance—as are most residential refrigerators—with a

control application that may easily reside on smart appliances, utilizing the

resident processing and communications power for additional aspects of appliance

operation that are “Grid Friendly” in one or more of several ways.

Grid Friendly refrigerators avoid loads to the grid during peak periods in ways transparent to the occupants. One simple means is locking out defrost cycles during peak periods. Defrost loads in residential refrigerators comprise approximately 7% of the load in residential refrigerators, and are 10% more likely to occur in the morning and evenings coincident with most utility peaks. A similar lockout strategy can be applied to anti-sweat features.

Another means of avoiding peak loads is precooling the refrigerator slightly—a few degrees Fahrenheit—prior to the peak period, in combination with or alternatively raising the thermostat setpoint slightly. This allows the refrigerator to coast through the peak period with no or fewer compressor cycles. This strategy is readily enhanced using thermal storage. This might be in the form of ice or other phase-change materials, integrated into the compartments or added in the form of a container placed on a shelf.

Since refrigerator usage in residences coincides with peak electrical loads—about 10% above average—energy efficiency measures benefit when the compartment doors are open reducing peak loads even more than average loads. These energy efficiency measures include locking out circulation fans—used in frost-free models—to avoid their tendency to force out cold air when the door is open, at least for short periods up to a couple of minutes. It also includes utilizing lower-wattage or compact-fluorescent lamps, or illuminating through “windows” with lamps located outside the compartment insulation.

Grid Friendly refrigerator control actions may be scheduled routinely. They also may be dispatched by a remote operator on an as-needed basis, or automatically respond to real-time pricing signals, via electronic communications pathways such as power-line carriers, modem, Internet, wireless communication or other digital communication links not yet developed. The advantage of dispatch is that the control strategy need not be implemented everyday.

Response to real-time prices may be conveniently and efficiently generated using a two-dimensional thermostat—the subject of a separate invention report—with price as the second dimension. The system’s control strategy and response also could adaptively include learned knowledge of the occupants’ patterns of refrigerator use to optimize the control either for the grid benefits or the occupants’ convenience, including not responding at all to the signal.

Grid Friendly refrigerators include actively-controlled, short-term support for the grid when it is in a stability crisis. Defrost elements can be turned off for short periods of time, typically less than 10 seconds but up to a few minutes. Compressor loads can be reduced for similar periods by use of a hot-gas bypass valve, variable speed motor or reversion to a single-stage operation in multi-stage machines. Compressors may be turned off or thermostat setpoints may be raised slightly, for a few minutes. The defrost elements (lamps and fans) may be actively cycled over very short periods—up to a few seconds—over a span of up to a few minutes to help stabilize grid fluctuations.

|

|

Grid crises may be self-sensed in Grid Friendly refrigerators using sensors and processing on-board the appliance or serving the entire building, or may be signaled by a remote operator through the communication pathways noted above. Response to grid crises may be conveniently and efficiently generated using a two-dimensional thermostat—the subject of a separate invention report—with a grid-stability criterion, such as voltage or frequency, as the second dimension.

Grid Friendly refrigerators will passively support grid stability in crises by modifying their current-voltage characteristics to act as constant impedance loads instead of constant power loads, so that their power draw does not increase when voltage sags occur.

[an error occurred while processing this directive] Grid Friendly refrigerators will be capable of supporting end-use blackouts, where an operator attempts to manage a crisis by turning off an entire class of appliances in lieu of a total electrical blackout.

Grid Friendly refrigerators will be capable of ramping—using variable speed drives, multi-stages or hot-gas bypass valves. They also are capable of randomizing, or scheduling their startup after power outages to minimize cold-start pickup loads faced by the grid, either independently or in response to signals from an operator.

A friendlier grid

If the above level of control is achievable in a small refrigeration

appliance imagine how large chillers, HVACR equipment, industrial cooling

systems and food equipment can be orchestrated to provide a friendlier grid.

Concepts such as off-peak cooling storage, speed control and load rolling would

provide a significant impact on the electrical grid and the refrigeration

industry.

The opportunities are real, significant and immediate. The critical shortage of electricity in the United States is driving utilities and regional Independent System Organizations (ISOs) offer significant incentives on electricity loads that can be curtailed at peak times. Issues driving the need and opportunity of DR include:

• Spiraling energy costs;

• Shortage of electric generation at peak periods;

• Demand for energy efficient green buildings;

• Increase awareness for reducing carbon footprint; and

• Availability of communication and control technologies.

The value of bought-back peak demand will open many new opportunities in the industry to not only provide response technology, but better interactive Web-based control of all refrigeration equipment. The value of Web-based performance evaluation and troubleshooting is becoming mandatory to the refrigeration industry as less expertise is being required to keep more equipment running at a new level of efficiency.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]