December 2007

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

December 2007 |

[an error occurred while processing this directive] |

|

|

MatrikonOPC White Paper |

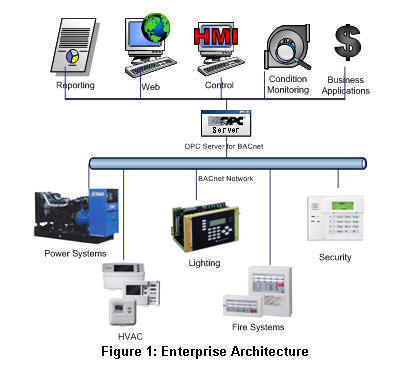

With today’s building automation systems, the walls can talk. So can the heating and air conditioning systems, the lighting, the fire detectors and the security system. They all have important information to relay about energy management, optimized operating conditions, and improved asset utilization. Unfortunately, they are all speaking different languages and running into application barriers. These systems can be connected and the obstacles overcome using standard, open protocols: OPC and BACnet.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

Building systems are more than HVAC

All too often people think of building systems as just heating, ventilation

and air conditioning (HVAC) systems, but a truly integrated system covers much

more. Modern building management monitors and operates all technical facilities:

heating and air conditioning, security and surveillance, lighting, fire and

safety systems and other equipment. Managing these data sources ensures optimal

building performance by enabling control of building systems in an integrated

manner. A major problem for organizations is inefficiencies, and the solution to

that problem is enterprise systems.

Fully integrating the enterprise also involves information from the systems within the buildings: plant floor manufacturing systems, energy and power monitoring equipment, utility operations and industrial control systems. The fundamental enabling component for all of this is the availability of real-time information. Integration of the systems, using standard protocols like OPC and BACnet (Building Automation and Controls network), is needed to fully realize optimization possibilities.

What are the advantages of integration?

Integration of systems, enterprise-level connectivity, and a new generation

of efficient and intelligent hardware provides advantages that businesses can

use to make buildings more productive and less expensive to operate. There have

been numerous studies on benefits of integrating building systems. Recurring

results include improved monitoring, alarming, diagnostics and troubleshooting

associated with singular point of control. Other conclusions include lower

maintenance costs, optimized energy usage, improved safety and/or security

measures, and improved employee productivity.

In the current world of high oil prices, political instability, and concerns on climate change, other key benefits are those associated with energy savings and reduced emissions. What is the potential in this area? The following is an excerpt from the testimony of the American Institute of Architects President RK Stewart, FAIA, before the Subcommittee on Energy of the Senate Committee on Energy and Natural Resources1 on the issue of energy efficiency in buildings:

“According to the Department of Energy’s Energy Information Administration, buildings and their construction are responsible for nearly half of all greenhouse gas emissions produced in the U.S. every year.“

An essential part of reducing the emissions problem is to optimize the way energy is used today, and building systems are a significant portion of overall energy consumption. In order to improve the use of existing systems, timely access to data is required to determine how best to control energy usage. Ultimately it’s all about connecting the assets in the enterprise. Making the right protocol choices is important to achieving this connectivity.

Talking the Talk

When the suppliers and consumers of data are specialized, an

industry-specific protocol is needed for maximized control and functionality. As

the data sources and end-user applications become broader and usage more varied,

a more general, widely implemented protocol is preferred. The open, standard

protocols BACnet and OPC fit the bill perfectly.

Historically the building automation industry has been dominated by proprietary systems. Over the last ten years a few protocols have gained acceptance and are now commonplace in the building automation industry. The main protocols are BACnet and LonWorks®, with wide support for Modbus, a more general industrial automation protocol. Among these, BACnet is the only true open standard that is designed specifically for the building automation industry. The BACnet protocol is an American national standard, a European pre-standard, and an ISO global standard used in Building Automation. The BACnet standard is supported and maintained by the ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) Standing Standard Project Committee.

[an error occurred while processing this directive] As an industry standard, BACnet provides a level of assurance that various compliant devices from different vendors work together. It provides a set of rules that govern the exchange of information over the network. BACnet-compliant lighting, HVAC, security and other systems and devices from multiple vendors can be attached to a network, enabling single-seat, global control and access to all connected building control systems. According to a study conducted by the BACnet Manufacturers Association, in the year 2000 more than 19,000 installations were found to be in operation.

Interoperability: Transforming Data to Information

Standardized access to the raw data available in the various building

automation devices is only one part of the complete solution. There are

significant productivity enhancements and optimization opportunities available

to manufacturing operations by integrating their building automation and

industrial automation systems. For example, integrated building automation

systems used to monitor and control mission-critical environments can send

information about the quality of the manufacturing environment to industrial

control systems. Optimization tools within industrial automation systems can

then correlate variations in the manufacturing environment with scheduled

workflows. Just as open connectivity to various automation devices offers

advantages; similar opportunities exist for standardized interoperability to

enterprise level applications such as user interfaces, historical data storage,

and optimization and analysis tools.

OPC Provides the Ways and the Means

In the industrial automation world, OPC has long been recognized and used to

provide standardized, real-time data access to disparate systems. Industrial

processes and manufacturing sites produce tremendous amounts of real-time data

which require transformation into useful information. In terms of using OPC to

connect systems, building controls, HVAC, lighting and security devices are all

assets as well. As with other industry verticals, OPC servers are available for

a wide range of building automation protocols, including BACnet, LonWorks® and

Modbus. OPC servers provide connectivity to a wide range of advanced

applications, such as decision support systems, historical analysis, process

optimizations and energy calculations and other high-level information

processing systems. Simplified access to real-time data and enterprise

connectivity enables applications to provide optimizations such as:

• Centralized management systems for maintenance and energy monitoring

• Historical data analysis of peak demand and optimizations of utility costs

• Unified data processing and troubleshooting of real-time systems

• Standardized connectivity to cross platform and multiple vendor products

• Competitive system expansion

Harness the Power of Open Standards

The cornerstone of an enterprise architecture that utilizes the power of the

OPC and BACnet standards is an industrial-grade, OPC-compliant server that

supports a wide range of BACnet functionality and configuration options. The

MatrikonOPC Server for BACnet provides real-time data access between OPC systems

and building automation system devices supporting BACnet (Annex J compatible

devices). Communication is conducted via Ethernet or serial RS-485 (providing

Cimetrics USB-to-BACnet MS/TP interface) using the Cimetrics BACstac protocol

layer. In addition to the robust OPC- compliant framework, the server supports

the following operations:

• Automatic device discovery and binding

• Automatic generation of OPC items

• Supported for most properties of standard and proprietary object types

• BACnet Read Property

• BACnet Read Multiple Properties

• BACnet Write Property

• BACnet Write Multiple Properties

• Write requests prioritization with write command priority

• Subscription to Change of Value (COV) Notification

• Latest BACnet specification compatible with the OPC Server acting as a BACnet device on the network

The MatrikonOPC Server for BACnet enables real-time data transfer from the building automation devices to the enterprise applications that transform that data to information, and information to savings.

More Talk, More Action

In this case the old adage of ‘less talk, more action’ doesn’t hold. The

more ‘talk’ or data access between the applications, the more action can be

taken. Organizations are hearing the call for action from many sources:

government regulation on energy usage, increased focus on green operation and

emission reductions, as well as the attraction of cost savings and improved

operations. There is a trend to integrate building automation systems to

industrial applications and the rest of the enterprise. Open standards play a

major role in designing an integrated architecture, and BACnet and OPC are

clearly at the forefront of interoperability in their respective domains. If

these walls could talk, we know what they would be saying.

Bibliography:

[1] The American Institute of Architects, Statement of RK Stewart,

President. “Energy Efficient Federal Buildings” before the United States Senate

Committee on Energy and Natural Resources Subcommittee on energy. (http://energy.senate.gov/public/_files/RKStewartatSenateEnergyFebruary82007FINAL.pdf)

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]