December 2008

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

December 2008 |

[an error occurred while processing this directive] |

|

|

|

How much do you spend a month fuelling your boiler? Is there a particular component decreasing performance? Would you know what to adjust if you realized money and energy were being wasted on an hourly basis?

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

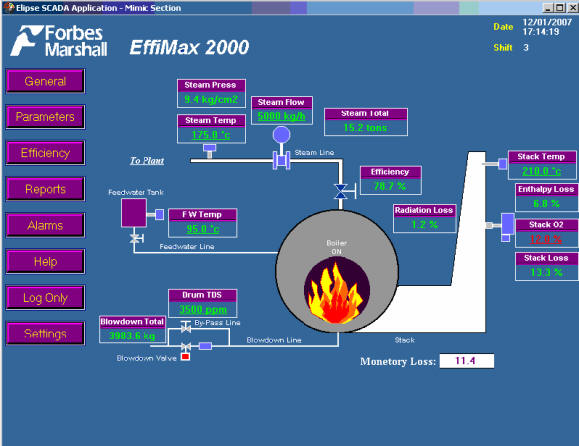

Forbes Marshall introduces the first complete boiler monitoring package… the EffiMax. This is a system designed to not only continuously monitor key parameters of boiler functions, but also to determine how much fuel is being consumed, how much steam is being produced, and how much inefficient stack and blow down operation and other losses are costing. A further step is taken by the system, by indicating instructions and solutions to minimise losses and increase overall boiler efficiency, for reduced fuel costs.

A central processing unit collects and calculates key data, including efficiency and monetary loss, based on fuel input, steam output, and other parameters necessary to continuously measure boiler performance in terms of energy consumption, efficiency, and safety. The technology is adaptable to any existing boiler, whether gas, oil, or solid-fired. Since it is application specific, system components vary, but most include various temperature sensors, steam flow metres, automatic blowdown control systems, and stack oxygen analyzers.

With a plug-and-play

design, operators can easily view all incoming data either on-site via the touch

screen on the central unit, or up to a kilometre away on a P/C loaded with a

specialised software program that permits data as far back as a year to be

analyzed and studied.

With a plug-and-play

design, operators can easily view all incoming data either on-site via the touch

screen on the central unit, or up to a kilometre away on a P/C loaded with a

specialised software program that permits data as far back as a year to be

analyzed and studied.

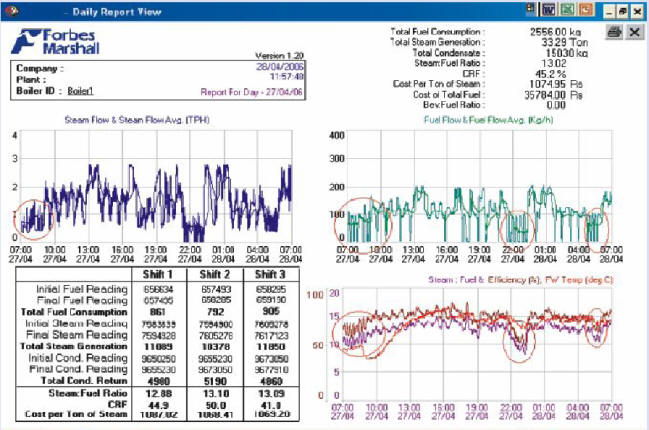

The EffiMax informs, so corrective action can be taken. It is effectively a compass, telling engineers or operators to go to an exact point within the system so that the appropriate changes can be made. Operators input their preferred limits, for example, stack oxygen levels, and the system provides visual signals when maximums are reached. Since data is continuously compiled, operators can pin-point the exact instant in time when functioning peaked or bottomed-out. For instance, the graph in the top right corner of the daily report below shows that between 7:00am and 6:00pm, 10:00pm and 12:00am, and 4:00am and 6:00am, the boiler was shutting off and on numerous times.

To most operators this would be normal activity….until the graph below (bottom right of screen) is seen, indicating the steam-to-fuel ratio. Notice the dips in the ratio at the exact same times also dipped. Yes. The constant on and off cycles significantly impact efficiency, costing extra money and wasting unnecessary amounts of energy. How likely would the operator have known this without the EffiMax? This is only one example of the insight the EffiMax can provide, which can ultimately translate into energy and significant monetary savings.

When utilised to its fullest potential, the EffiMax has been shown to significantly reduce fuel bills, increasing profits for users. For instance, a pharmaceuticals plant reduced fuel usage by 25,000 litres per month after the EffiMax revealed significant heat loss from the stack in a 44,000 pound per hour boiler. This adjustment ended-up improving boiler efficiency by 6%, resulting in the system paying itself off within 3 months.

Since the EffiMax is designed to detect inefficiencies, which ultimately save money, the product can be considered an investment that pays for itself. Most importantly, it has been proven to aid in conserving significant amounts of energy.

It has already received formal and informal praise. The EffiMax was awarded the 2006 National Award for Excellence in Energy Management by the Confederation of Indian Industry (CII). And one Canadian utility provider was quoted as saying, “this will change how everything is done.”

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]