|

February 2014 |

[an error occurred while processing this directive] |

|

Integrated

Automation Systems Improve Building

Automation

|

Marcia Gadbois, Vice President InduSoft, Invensys |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

A monumental shift is

occurring in building automation. The formerly

separate silos of security, HVAC and lighting control are being

replaced by a completely integrated building automation system (BAS)

that maximizes energy efficiency while also providing greater comfort

and safety for the people living and working inside these structures.

The initial transformation of what once were largely

mechanically-driven systems into IT-based solutions was the result of

the introduction of affordable controllers, PCs, Windows-based software

and better communication networks, particularly Ethernet.

Today, the Internet and its related technologies are ushering in the

next generation of building automation, which delivers efficiency gains

through easier and more integrated control. From smart buildings to the

smart grid, new solutions offering easier remote connectivity and

interoperability among different machines and systems will drive the

BAS market.

Many building automation developers and integrators are reluctant to

adapt to these changes because they are overwhelmed at the thought of

integrating several systems, and fearful of the required time

commitment.

However, they need to recognize the latest generation of BAS is being

driven by businesses demanding greater control, better energy

management and more automation. Fortunately, new technologies exist

that can assist in creating a 21st century BAS. The slow

adopters

should also understand that the system providers who offer smart

solutions that businesses want will have substantial competitive

advantages over those who can’t.

More Customized Control

The one-size-fits-all approach to building control is quickly

disappearing. Today’s companies prioritize productivity improvement and

the elimination of unnecessary costs. One of the ways they’re achieving

these goals is by demanding more tailored control over lightning,

temperature and energy usage.

Buildings are among the largest electricity consumers in the North

America. Their HVAC and lighting systems typically use the most energy,

which puts them at the top of the list for improvement. One of the

problems is that HVAC systems typically run on fixed schedules, without

any granular control based on detailed occupancy information, sunlight

or external weather conditions.

Connectivity among systems can greatly reduce energy usage by providing

this granular control. For example, security sensors that send

information to a lighting control system to illuminate rooms when

people enter are becoming commonplace. As more control systems silos

are integrated and as devices become smarter, improvements and

efficiencies will increase at both the individual level and for the

system as a whole (Figure 1).

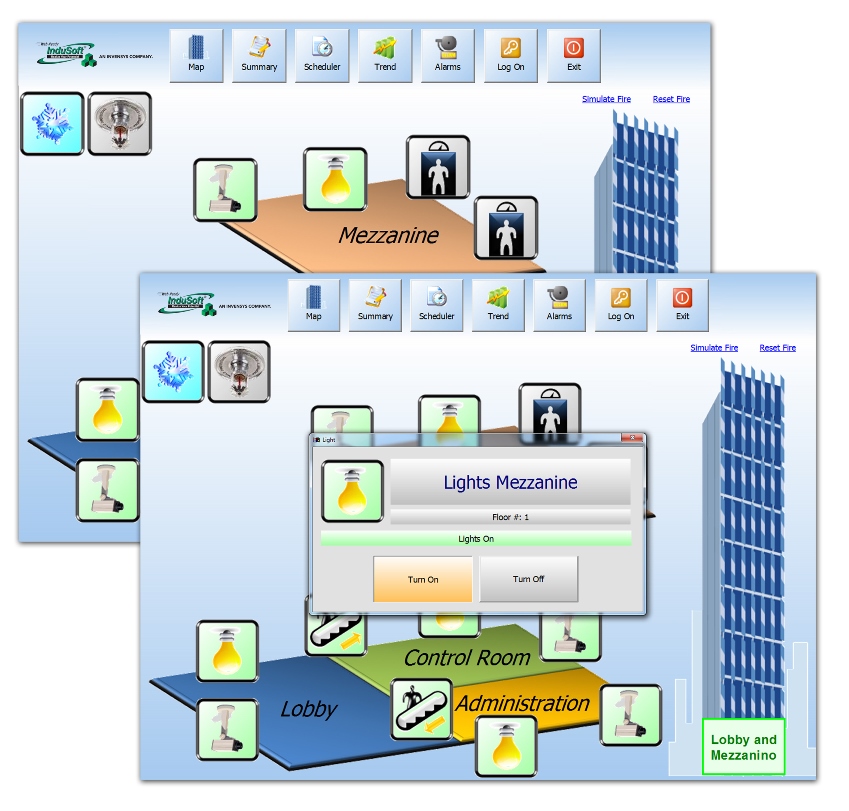

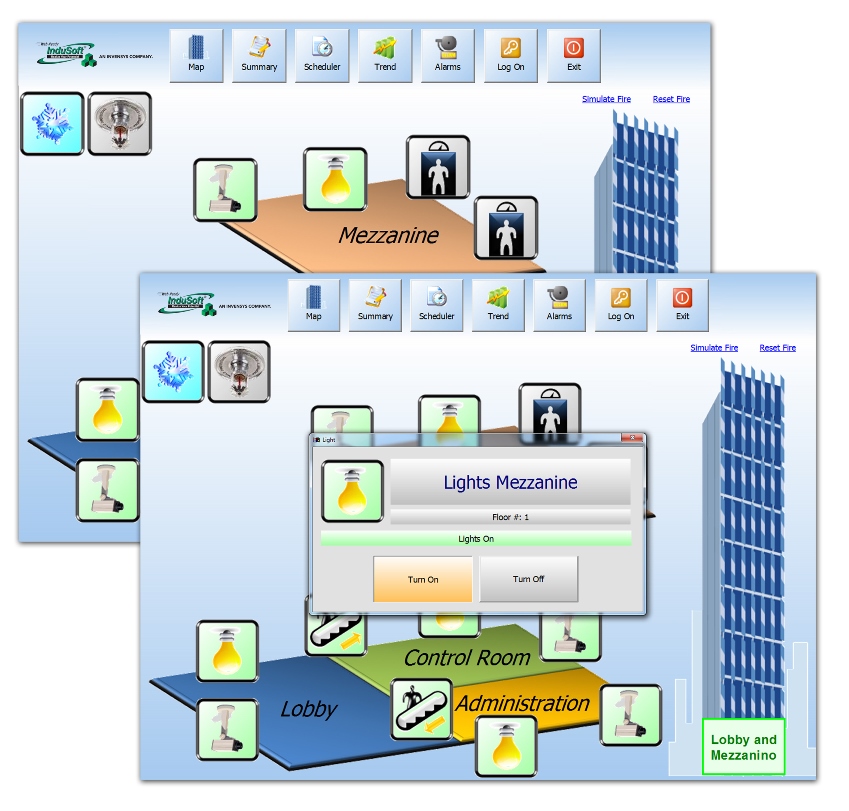

Figure 1: Staff

reductions and increased

need for efficiency are driving

the demand for an integrated BAS that enables users to interact with

data from multiple systems on one screen as well as drill down for more

in-depth views.

System Integration Benefits

With fewer workers, companies require user-friendly, more automated

control. They can’t afford to have employees roaming buildings to

change set points or determine where and why a problem is happening. In

fact, most facilities don’t even have sufficient staff to monitor

separate workstations for multiple, isolated systems.

Compounding the staffing problem, most of these automation islands have

their own screen displays and commands, making it expensive and time

consuming to train workers. The silo approach also forces maintenance

to be more reactive than proactive. Without the ability to easily

understand how the BAS is performing as a whole, it’s very difficult to

see how problems that arise in one area can affect other systems, or

how improvements in one system element can increase overall efficiency.

Through the interconnection of individual systems, facility workers

have better control of the entire building and can respond to possible

events before they escalate, often by executing only a few commands

from a PC that is monitoring all of the control systems in the

building. Moreover, smart systems can modify set points to respond to

conditions without the need for an operator, further reducing required

staffing levels.

In addition to maximizing labor productivity within the building,

highly automated integrated systems can also provide new opportunities

to save money, such as by using pricing information from utilities to

take advantage of energy reduction incentives. For example, an

integrated lighting system can adjust according to information from

other internal systems, such as security showing empty offices. An

integrated HVAC system can temporarily cut its power consumption to

decrease energy use during peak periods as communicated by their

utility.

An integrated BAS increases worker productivity by creating a more

comfortable environment. Perhaps most importantly, it can also improve

worker safety.

Better Safety

When considering safety, there’s little doubt that integrated BAS provides many advantages as compared to a system of separate silos. This can be easily seen with a fire protection system which is integrated with other automated systems such as HVAC, lighting, elevator control, security, and others—all to ensure people, equipment and systems respond faster in emergencies when every second counts.

Consider a scenario where a fire starts in a facility with an

integrated BAS. The smoke detectors alert operators to a potential

problem in an office on the third floor. Since the door control,

sprinklers and video surveillance are monitored from a single point,

the facility crew can make sure people are being evacuated, as well as

zero in on exactly what is occurring in the third floor office.

This BAS also includes embedded human machine interfaces (HMIs), which allow information to be communicated throughout the facility to any worker with a properly configured smartphone or tablet. The concept of embedded HMIs, as opposed to traditional PC-based HMIs, will be covered in detail in the next section.

Smoke detectors would immediately send an alarm to the intercom system to instruct workers as to the path each should take to exit the building safely, without any human involvement needed. The smoke detectors would also send messages to security systems to recall all elevators to the first floor, to open all doors in unaffected areas, and to close doors near the fire after the sensors indicate that occupants have left the area.

Fans would start and stop depending on their proximity to the fire. The

integrated, smart BAS would ensure that the proper sequence was

followed to protect lives and property, so fans would only start after

the dampers opens to avoid compounding damage from the fire.

In summary, an integrated BAS provides a host of benefits as explained

above, and as listed in Table 1.

Many of the actions performed by an integrated BAS happen automatically, with monitoring and any manual overrides performed via either a PC-based HMI, or by one of several embedded HMI platforms.

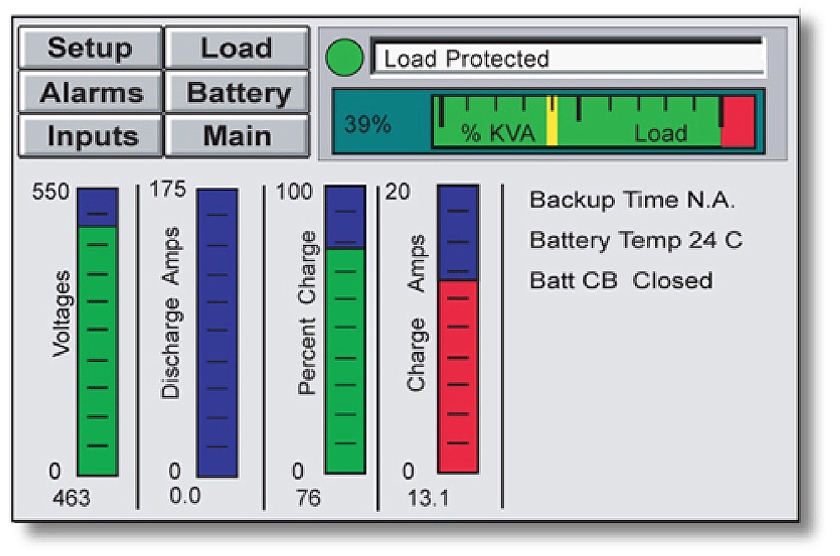

The Growth of Embedded HMI

While a central PC-based monitoring and control system will continue to

play an important role in an integrated BAS, embedded HMIs will

increasingly take on a larger role. An embedded HMI is simply a device

other than a full-featured PC that runs HMI software. Typical examples

are CE-based devices, tablets and smartphones. The advantage of an

embedded HMI is lower cost, and freedom of movement for tablets and

smartphones (Figure 2).

Although embedded HMI software must be designed for small footprint

operating systems with limited memory such as Windows CE, these

platforms are expected to deliver nearly the same functionality as a

PC-based supervisory control and data acquisition (SCADA) application.

The embedded HMI software must therefore include an object-oriented

database, math functions, archiving and alarm capabilities and more.

Furthermore, it must provide all this functionality scaled for

acceptable performance on the chip set of a device with much less power

than a PC.

Figure 2: Embedded HMIs with user-friendly graphical interfaces and SCADA-like functionality cuts costs of providing operator interfaces throughout a facility.

These types of advanced features sets, however, are almost useless

without the ability to communicate with the wide array of hardware and

software typically found in an integrated BAS. Therefore, the ability

to easily interact with other networks and hardware types will soon be

essential for both PC-based and embedded HMIs, and closed proprietary

systems will become relicts of the past. In response, modern embedded

HMI software has multiple native drivers, OPC connectivity and other

features for seamless integration.

Demand for Remote Access

Today’s business world demands wireless communication, advanced

functionality and remote connectivity. Smaller facility staffing levels

means workers must monitor more areas at the same time. Fortunately,

relatively low cost tablets and smartphones coupled with the right

embedded HMI software have enabled a highly mobile workforce to achieve

the required monitoring and control.

Many companies are going a step further to cut costs by adopting “bring

your own device” (BYOD) policies. While this significantly lowers IT

purchasing and maintenance expenses, it can be difficult to implement

if the HMI software only supports certain operating systems, such as

Apple’s iOS.

Although Androids and tablets have a wider user base than Apple

products, traditionally creating apps for iPhones and iPads has been

easier because vendors don’t have to develop for the wide array of

operating systems and screen sizes in the Android and tablet market.

Fortunately, a small number of HMI software suppliers have solutions developed in platforms that offer HTML5 support for their embedded HMI software. This means that all devices with an HMTL5 browser have the same visualization and interaction capabilities, regardless of the operating system (Figure 3).

Figure 3: Develop once, immediately view anywhere by using HMI software with HTML5 support.

No longer will users have to wait months for an app to be developed for

their particular device, or be forced to use slow browser-based

applications that don’t size correctly for their screens. These

new HMI software packages enable projects to be created once then

deployed instantly for multiple devices, providing a unified experience

across an entire system: PC-based HMIs, Windows CE HMIs, smartphones,

iPhones, tablets and iPads.

Smart Buildings Require Smarter Embedded HMI

An integrated BAS requires the embedded HMI on devices to deliver more advanced performance than simply turning on a light by pressing an on-screen button. The embedded HMI device will need to receive and provide data to and from other systems, so that the operator can see that the control system has dimmed the light when the window shade was automatically raised.

Embedded HMIs will be required to communicate directly with other devices and systems, and some will be directly linked to external systems as the traditional one-way power stream turns into the smart grid. Not only will the smart grid communicate with individual buildings, but also with embedded HMI devices inside the building.

In order to achieve optimal building automation performance, embedded

HMI devices will be required to provide real-time data to systems and

operators. Even devices with no local operator interface will need to

have trending, reporting, archiving and other diagnostics that can be

easily accessed by authorized users via a smartphone or a tablet.

Workers will need to debug, test and troubleshoot embedded applications remotely as well as locally to save time and money, especially for systems managing multiple locations. Users will come to expect the ability to trigger screen changes, set values and drill down from wherever they happen to be located.

For building automation system suppliers and integrators, this need for advanced functionality can seem daunting at first. They will have to create systems where real-time data must be presented in user-friendly graphical interfaces with charts, diagrams and even video displays. They will also need to deliver embedded HMI functionality that closely matches that of PC-based SCADA systems, including the ability to send emails and alarms messages. They also realize they must do this for the different screen sizes and operating systems found on smartphones and tablets.

[an error occurred while processing this directive]

Fortunately, there

are affordable HMI software solutions that can help

them overcome these challenges. These software packages offer

comprehensive feature sets that enable developers to easily create

highly customized user interfaces from extensive symbol libraries, and

the ability to import graphics of various formats.

These advanced HMI software packages provide the ability to develop once and deploy on any supported Microsoft Windows-based operating system. These latest software solutions also solve the problem of delivering remote accessibility to devices ranging from tablets to smartphones by offering HMTL5 support, which provides correctly sized screens and similar functionality to almost any device. Table 2 list features that users should demand from their embedded HMI software.

Integrated automation and advanced embedded HMI may seem like they’re

simply complicating building automation systems to provide a “wow”

factor for users. However, the development of the smart grid along with

companies placing more emphasis on improving energy efficiency and

safety is the impetus for the smart BAS.

Thus, building automation system developers who can’t provide

commercial business owners with the systems they demand will see their

sales volume drop sharply, especially when new technologies are making

it easier than ever for them to satisfy customers’ demand.

Table 1: Benefits of Integrated BAS

• Comprehensive monitoring and control systems

• Improved energy efficiency

• Reduced facility staffing requirements

• Better worker comfort and safety

• Easier troubleshooting and system improvements

• Greater ability to benefit from utility and

government incentives

Table 2: What to look for in

Embedded HMI Software

• Designed specifically for embedded OS

• Seamless integration with multiple systems and

hardware

• Full, SCADA-like functionality

• User-friendly graphical displays

• Extensive symbol libraries and templates

• Develop once, deploy anywhere configuration tools

• Easy remote connectivity from myriad devices

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]