January 2008

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

January 2008 |

[an error occurred while processing this directive] |

|

|

Mike Schell |

Overview

The role of CO2 demand controlled ventilation in reducing energy costs in building with high variable occupancy is well known. What is less well known is the role CO2 sensors can play in providing a feed-back control to ensure that minimum outdoor air settings are not over-ventilating spaces and wasting energy. This second benefit of reducing over-ventilation is applicable to any building density or type. This is particularly the case for existing buildings that have operated for years with minimal attention to outside air systems.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

The

results of an EPA study of the ventilation systems in 100 typical commercial

buildings was presented in an April 2005 article in the ASHRAE Journali

. Its findings suggested that the ventilation systems of many buildings may not

be operating as designed. Some further conclusions of this study are summarized

below.

The

results of an EPA study of the ventilation systems in 100 typical commercial

buildings was presented in an April 2005 article in the ASHRAE Journali

. Its findings suggested that the ventilation systems of many buildings may not

be operating as designed. Some further conclusions of this study are summarized

below.

Measured outdoor airflow rates were quite different than the design values for the buildings studied. While not necessarily unexpected, the findings highlight the need for good system commissioning and maintenance, if design intent is to be realized in practice.

Mean outdoor ventilation rates of the buildings studied was 117 cfm per person.

Average per person ventilation rates were 28.9 cfm per person.

83% of buildings had ventilation rates over 20 cfm per person recommended by ASHRAE.

17% of the buildings had ventilation rates below 20 cfm per person.

Building densities assumed in the design stage, or as dictated by common guidelines often did not reflect actual densities and were often contributing factors to over-ventilation.

You Cannot Control What You Do Not Measure

Outdoor air delivery to buildings is a critical part of building operation.

Code required ventilation rates provide fresh air to building occupants.

Outside air is used to pressurize buildings in order to control infiltration and maintain comfort.

When conditions are correct, outside air can be used for free cooling, commonly called an outdoor air economizer function.

Outdoor air can also be a significant component of building heating and cooling costs. Ironically, outdoor air introduction to buildings is one of the few major energy consuming features of a building that is typically not measured or controlled on a real-time basis. Based on the old quality mantra “you cannot control what you do not measure”, and given that most buildings do not measure outdoor air, it is likely that many building air intakes are bringing in more air than is necessary as suggested by the EPA study. This can have a significant impact on both energy costs and occupant comfort.

Unlike many operating components of a building, there is no real feed-back control to make sure outdoor air delivery systems are operating as designed. As a result most building owners are completely unaware as to whether they are utilizing an appropriate amount of outdoor air or if they may be over-ventilating.

In rare cases, air intakes are balanced to match the building design ventilation rate. However, once balancing contractors walk off the site there is no assurance that what ever was set will remain one day, one year or ten years after that adjustment. Also given that design ventilation rates are often calculated before the building is occupied, the ventilation levels set may not reflect the occupancy that occurs after the building is initially commissioned.

If the building uses variable air volume systems, the amount of outside air introduced to the space will vary depending on cooling demand of each zone. As a result, these systems are usually balanced and set to bring in the design ventilation levels when the system is operating at its lowest capacity, in order to ensure adequate ventilation occurs at all times. As a result, buildings with VAV systems may be significantly over ventilating during other operating conditions particularly if the amount of outside air is controlled by a fixed outside air damper position.

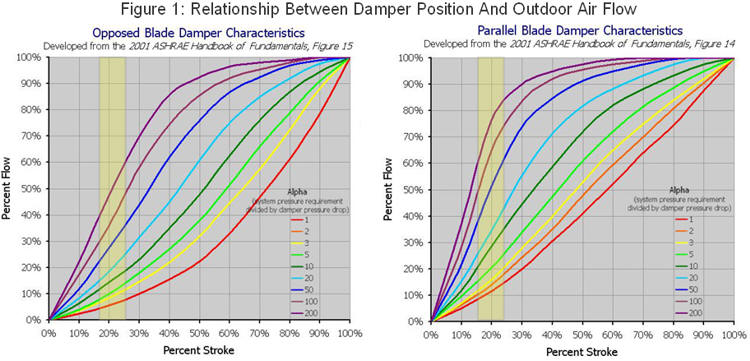

Often outdoor air dampers are arbitrarily adjusted without any real quantitative feed-back regarding the actual airflow that may result. In fact, one of the major reasons that most buildings are over ventilated is that a widely used rule of thumb is misinterpreted by most building owners and contractors. It is the 20% rule. That is that 20% of the air circulated by an air handler should be outside air and 80% should be recirculated air. This is a problem because many operators think that if they set the dampers at a 20% throw or stroke position that it will yield 20% outside air delivery. In reality, the throw position of the damper has almost no relationship to actual outside airflow delivery as shown by the two charts below.

Source: Portland Energy Centerii

Figure 1 shows a couple of graphs developed by the Portland Energy Center that shows the relationship between damper position and actual airflow. The horizontal axis on the above graphs shows the percent throw/stroke position with the area around a 20% open position highlighted. The colored lines traveling through the highlighted area represent the ratio of system pressure requirement divided by the damper pressure drop, which is dictated both by the airflow of the system and the size and design of the dampers.

The graph above demonstrates that choosing a 15 to 20% open position for the design ventilation rate for an air handler could yield 5 to 70% airflow with the chance of erring on the high side very likely. If a building uses variable air volume systems or introduces air to the building using variable speed drives interlocked to a manual adjustment or pressure control, it is likely the building may see the full range of outdoor air percentages over a typical daily operating cycle.

Such is the state

of most building air intakes today. We just don’t know it because we are not

measuring it. The result is that most buildings are wasting energy to condition

large amounts of outside air resulting from the arbitrary setting of building

air intakes.

Such is the state

of most building air intakes today. We just don’t know it because we are not

measuring it. The result is that most buildings are wasting energy to condition

large amounts of outside air resulting from the arbitrary setting of building

air intakes.

Modulating Ventilation Based On Occupancy

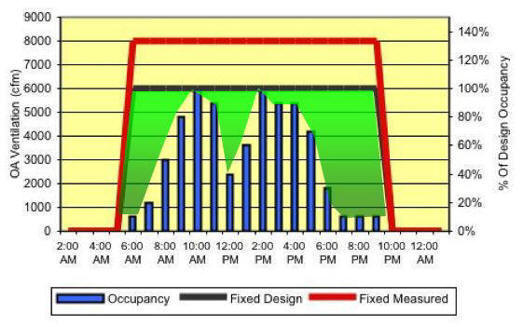

CO2 ventilation control, often called CO2 Demand Controlled Ventilation (DCV) is a well documented method of controlling the delivery of outside air to buildings based on occupancy. CO2 based DCV has demonstrated significant energy savings in highly variable, higher density applications such a gymnasiums, auditoriums, classrooms and retail spaces and hospitality facilities. The chart to the right shows how occupancy might vary in a typical building over the course of a day. The dark green line above the shaded area shows the ventilation that would be needed if a fixed amount of ventilation is provided at the design ventilation rate (target maximum occupancy times the target ventilation rate (typically 15 to 20 cfm per person). Most existing buildings use the fixed ventilation strategy assuming the fixed outdoor position is set correctly to correspond to maximum occupancy. The shaded green area shows energy savings resulting from being able to modulate outside air delivery based on actual occupancy using CO2.

Using CO2

To Stop Over-Ventilation

Using CO2

To Stop Over-Ventilation

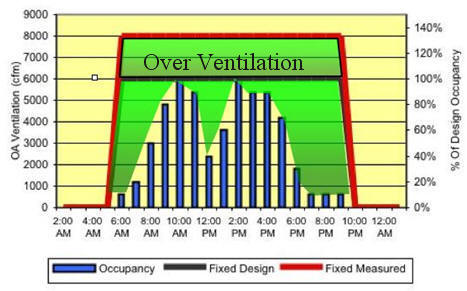

A second but less known benefit of incorporating CO2 DCV in any type of building is that the feed-back control that varies ventilation based on occupancy, will also find the natural minimum outdoor air position for the current occupancy in the space. As a result CO2 control eliminates the over ventilation that can occur when damper positions are improperly set as indicated by the red line on the graph. This second graph shows the additional saving that CO2 can provide (darker green shaded area), by reducing over-ventilation. For many buildings the savings resulting from reducing the over ventilation error in their systems can exceed the savings delivered as a result controlling ventilation with CO2 based on variable occupancy.

Energy savings are important to any building owner, but probably more important is understanding how a building is operating at all times. If CO2 levels are monitored through a building control system, it can provide good feed-back to the operator if the building’s outside air strategy is working properly. For example if a significant deviation of CO2 levels from typical operating conditions is observed the building operator will know something has changed in the mechanical system. Very low levels of CO2 (close to outside levels of 400 ppm) can indicate that excessive ventilation is occurring. Very high levels of CO2 over 1100 ppm can indicate a lack of ventilation. By monitoring CO2 readings as part of a building control system, a building owner also now has a means to determine and document ventilation as part of a strategy of proactive maintenance or continuous commissioning. Even if outside air intakes are currently operating properly, monitoring CO2 levels can provide important feedback when a change has occurred.

Determining Energy Savings From CO2 Control

AirTest has developed the Ventilation Optimization Energy Analysis Programiii as a method for estimating possible savings from using CO2 control in a new or retrofit application. Designed to simulate the climate of 228 North American cities, the program utilizes user-inputted data on the building and local energy costs to estimate potential savings. Savings are expressed in dollars, fuel type (kWh and therms), and greenhouse gas emissions. The program also breaks out savings provided by variation in occupancy vs reduction of over ventilation.

Variable

Occupancy Savings: To estimate the variable occupancy savings from CO2,

the user inputs the estimated daily occupancy pattern similar to that shown

in the graphs above. Up to two weekly occupancy schedules can be created as

well as designated off days where the system would not typically operate.

Variable

Occupancy Savings: To estimate the variable occupancy savings from CO2,

the user inputs the estimated daily occupancy pattern similar to that shown

in the graphs above. Up to two weekly occupancy schedules can be created as

well as designated off days where the system would not typically operate.

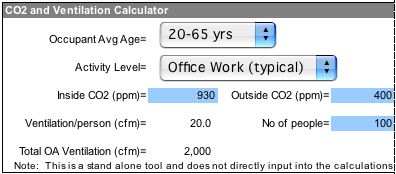

Over Ventilation Savings: To estimate over ventilation savings, the user can input a ventilation rate that is over the assumed design ventilation rate. This inputted ventilation rate can be based on actual measurement of the air entering the building using airflow sensors or by documenting peak CO2 levels to calculate the actual ventilation rate (A detailed paper on how to measure ventilation rates with the AirTest PT9250 CO2 monitor with data logging is available from AirTest upon request.)iv The program also includes a calculator which enables peak CO2 concentrations to be translated into a space ventilation rate. If no measured data is available, the user can input a ventilation value to test sensitivity of the analysis, say 5 cfm per person over the design ventilation rate.

Additional Energy Impacts From CO2

There are some additional benefits of CO2 based ventilation control that are not considered by this program but may have energy saving impact on many buildings.

In an actual building, fresh air may enter a space in the building that is vacant or under occupied and then be recirculated to other spaces in the building through the return air system. This recirculated or transfer air may further reduce the outdoor air requirement of the building and result in additional savings.

In many spaces like school classrooms or retail spaces, open doors or windows during a heating or cooling cycle may be providing plenty of outside air to a space without requiring its delivery by the mechanical system. If a CO2 sensor indicates air ventilation requirements of the building are met in the space, no unnecessary outside air will be introduced to the space through the mechanical system.

While an outside air flow measurement can indicate the total flow of outside air to the space, CO2 sensors will measure the effective ventilation rate, or the amount of ventilation getting to the space being monitored. CO2 sensors are really the only way that an operator can be sure a particular space is receiving the correct amount of outside air for the space occupancy.

By reducing over-ventilation in buildings in humid climates you may also improve comfort as described An ASHRAE Journal article on a CO2 retrofit of a commercial building in Atlantav . In the article it was reported that the operator of the building found that the CO2 retrofit eliminated complaints of uncomfortable moisture levels in the building by reducing excessive outdoor ventilation. Using CO2 measurements to quantify pre retrofit conditions it was discovered the building was being ventilated at an average of 37 cfm per person, almost double the intended design ventilation rate. The high perceived humidity level, was a direct result of the lack of dehumidification capacity in the cooling system to condition such unanticipated high levels of outside air. The system was never designed to bring this much outside air.

CO2 levels can be a good indicator of overall building system performance especially when compared to a baseline history of operation. If values significantly vary from normal baseline, problems like broken dampers, malfunctioning fans or other building system related issues can be quickly identified. As a result, CO2 sensor monitoring can be a key part of a program of continuous commissioning where building systems are continually monitored to ensure optimum performance.

Summary

[an error occurred while processing this directive] Historically, outdoor air requirements for buildings have been provided by fixed position dampers set to bring in enough air to meet maximum occupancy requirements that are estimated when the building is in the design stage. Due to the way dampers operate and given the misunderstanding of the 20% outside air rule of thumb, it is highly likely that many buildings are significantly over ventilated but do not know it. The EPA large buildings study discussed earlier, verifies this observation by confirming that over 83% of buildings studied were ventilated at over 20 cfm per person. This information points to the fact that outdoor air, a major contributors to building heating and cooling and dehumidification, is seldom measured or controlled after it is initially set up.

With the advent of CO2 sensing, there is now a way to provide control, based on real time feed-back, to outside air introduction to buildings that is directly related to real time use and occupancy of the building. This type of control can have an impact on ventilating the building based on occupancy but can also provide an automatic feed-back for the minimum setting of outdoor air intakes to eliminate costly over ventilation that can also impact comfort and building vulnerability to moisture related problems such as mold. Every existing building could benefit from this type of feed-back control. Outdoor ventilation can only be controlled if it is measured, and CO2 sensors offer an ideal, cost effective approach to finally controlling outdoor air delivery in buildings.

In order to assess the financial impact on buildings of embarking on a CO2 ventilation control strategy, AirTest has developed the Ventilation Optimization Energy Analysis (VOEP) program that can use building and local climate data to estimate the potential savings that will result from reducing over ventilation and modulating ventilation based on occupancy. The program also considers various fresh air economizer strategies and their impact on energy use in buildings. The analysis also evaluates a new approach involving using a centralized, weather station quality, dew point and temperature sensor for economizer control of all air handling units on a buildingvi as advocated by the ASHRAE Humidity Control Design Guidevii . It is important to note that as our buildings become more automated, and energy costs are a greater concern, feed-back control on all aspects of a building operation will become increasingly important. CO2 sensors are becoming part of a second wave of energy upgrades for buildings that can not only reduce energy, but also provide ongoing feedback to the building operator on how the building is operating.

If you would like more information on how to integrate CO2 control for better outside air control of buildings please contact us or visit our web site.

Web:

http://www.AirTestTechnologies.com

Phone: 888-855-8880 or 604 517-3888

Email: info@AirTest.ca or to contact the author

mike.schell@airtest.ca

References

[i]

A. Persily, J. Gorfan, G.

Brunner, Ventilation Design and Performance In US Office Buildings, ASHRAE

Journal, April 2005 (Available from ASHRAE Bookstore:

http://bookstore.ashrae.biz/template.php?AssetID=26

)

[ii]

Information obtained from the Portland Energy Conservation Center, as published

in CSE Magazine web log. Link:

http://www.csemag.com/blog/1250000325/post/1650010165.html

[iii]

The AirTest Ventilation Optimization Program is designed for us by engineers,

contractors and building owners using AirTest products. It is available on CD

by contacting AirTest at 604 517-3888 or emailing

info@airtest.ca .

Web based training on how to use the program is also available on request.

[iv]

AirTest PT9250 Guide, Link: http:www.airtest.ca/support/manual/PT9250guide.pdf

[v]

To learn more about using a centralized dew point and temperature sensor for

economizer control, contact AirTest for a copy of the Whitpaper: Economizer

Design Guide

[vi]

M. Schell, D.

Smith, Assessing CO2 Control In Retrofits, ASHRAE Journal, November

2002 Link:

http://airtest.ca/support/reference/article5.pdf

[vii]

L.

Harriman, G.Brundrett, R. Kitter, Humidity Control Design Guide for Commercial

and Institutional Buildings, Published by ASHRAE, 2001. Available form the

ASHRAE Bookstore

www.ashrae.org

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]