".......PCs running Wizcon that communicate over the network through Profibus-FMS and Profibus-DP bus protocols." Valerie Harding, eMation |

AutomatedBuildings.com

|

[an error occurred while processing this directive] |

".......PCs running Wizcon that communicate over the network through Profibus-FMS and Profibus-DP bus protocols." Valerie Harding, eMation |

At

the beginning of 1999, the Heiploeg shrimp

processing company relocated to a new building at Zoutkamp of the Netherlands. A

successful operation of the plant depended heavily on smooth and reliable

information flow between well-integrated systems, such as production and energy

control systems. Deventer (Netherlands)-based RBK Automation was chosen as the

main supplier and system integrator for the automation system. And eMation's

Wizcon for Windows and Internet was selected to control and monitor the plant.

At

the beginning of 1999, the Heiploeg shrimp

processing company relocated to a new building at Zoutkamp of the Netherlands. A

successful operation of the plant depended heavily on smooth and reliable

information flow between well-integrated systems, such as production and energy

control systems. Deventer (Netherlands)-based RBK Automation was chosen as the

main supplier and system integrator for the automation system. And eMation's

Wizcon for Windows and Internet was selected to control and monitor the plant.

As with all food-related products, Heiploeg is

required to meet very high hygiene standards. At the end of 1994, one of 13

plants at Zoutkamp virtually burned to the ground. Building a new plant and

integrating all the existing dispersed ones proved to be the best solution to

guarantee the company's continuity.

As with all food-related products, Heiploeg is

required to meet very high hygiene standards. At the end of 1994, one of 13

plants at Zoutkamp virtually burned to the ground. Building a new plant and

integrating all the existing dispersed ones proved to be the best solution to

guarantee the company's continuity.

Designing and Implementing the automation solution was assigned to RBK Automation whose mother company, RBK Group, has been involved in planning and implementing the entire project. Their experience and expertise helped Heiploeg to complete the automation project in time and according to the specifications. The system controls the cooling and freezing tunnels, the building's air conditioning system, the central freezing system, the processing lines for cooking, cooling, freezing, sorting and packaging, and the complete energy supply.

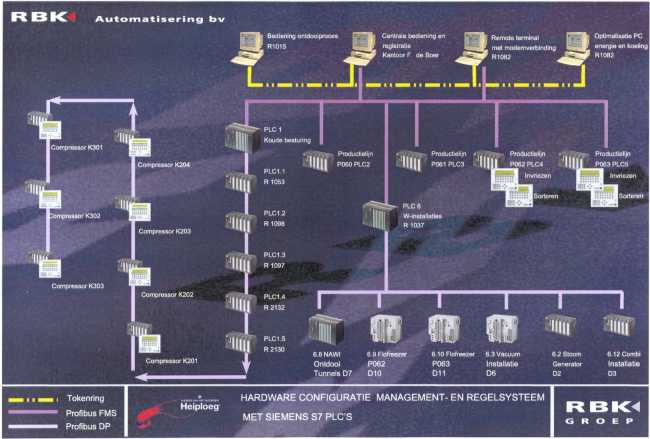

[an error occurred while processing this directive]The configuration consists of PLCs (mainly Simatic S7) and PCs running Wizcon that communicate over the network through Profibus-FMS and Profibus-DP bus protocols. Through Wizcon, the staff at Heiploeg control and monitor seven cooling compressors, cooling systems of the processing area, the defrosting tunnels, four processing lines, the combined heat and power plant, two flofreezers, the combined cooling/freezing process and some smaller parts of the plant that do not have their own dedicated controllers. Programming almost any PLC within the network can be done at the Deventer facility (about 150 km south of Zoutkamp) using a remote terminal and a modem.

Wizcon was chosen for monitoring and visualising all the materials and energy flows mainly due to its openness. This allowed RBK Automation to easily develop their own specific modules ('add-ons'). Another important factor that influenced Heiploeg 's choice of Wizcon is the timely technical support they received from the local eMation office at Waalwijk (in the south of the Netherlands, about 250 km from Zoutkamp). In addition, Wizcon offered most of the features that were required to create the application, including multi-user access, easy operation, configuration and programming, excellent communications using Profibus-FMS, Intranet and Internet, and paging capabilities.

The application includes a number of modules specifically developed by RBK Automation. The Deventer-based company added its own version of the Windows Explorer to Wizcon, as well as a module for setting the temperature in each area in 30 minutes intervals. By using the Explorer, the operator can get a close view of a specific part of the plant not only by zooming in and out on process images, but also by using the familiar Explorer-like structure. Using this capability, the operator can easily switch from one process screen to the other. This often proved to be a faster way than passing through all the process images. The Explorer is displayed in the same screen as the application itself. Adding this Explorer- like functionality can also be developed for other SCADA systems, but will require more efforts.

Future Plans Heiploeg is now looking into connecting their production and processing information systems to the financial systems. However, their first priority is to optimize the production processes within the new plant and implement Wizcon at some companies recently acquired by Heiploeg.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]