|

July 2013

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

A “REvolution” in Integrated Facility

Optimization

Ezenics Mobile: The Power of

Enterprise-Level Analytics, Work Order Management, and Building

Controls in the Palm of Your Hand

|

Jason

Fuller

Ux Design,

Development Liaison,

Ezenics, Inc. |

Scan a QR code or

asset tag on a machine and instantly know everything

that there is to know about it. Respond to analytics-driven work orders

and correct a variety of issues without even touching the machine. View

and modify the points on a machine using your phone as a remote

control, regardless of the underlying BMS or brand of equipment. These

are some of the things that can be accomplished with only a few thumb

taps on Ezenics Mobile, a cloud-based, agnostically integrable mobile

application designed to provide service technicians with critical

information and refined, “on-the-go” access to enterprise-level

facility optimization systems.

At the Realcomm Intelligent Buildings Conference

(http://www.ib-con.com/),

large touchscreen kiosks made to look like

giant mobile phones were showcased throughout the halls and gathering

areas of the convention center. The interactive displays gave facility

managers, technicians, and members of the intelligent buildings

community a chance to try out the live Ezenics Mobile application in a

big way. In addition, conference attendees were given cards with

scannable QR “asset tags” on them, which allowed them to just as easily

pull up the application on their own mobile devices. Scan the QR code

on this article to try it out!

At the Realcomm Intelligent Buildings Conference

(http://www.ib-con.com/),

large touchscreen kiosks made to look like

giant mobile phones were showcased throughout the halls and gathering

areas of the convention center. The interactive displays gave facility

managers, technicians, and members of the intelligent buildings

community a chance to try out the live Ezenics Mobile application in a

big way. In addition, conference attendees were given cards with

scannable QR “asset tags” on them, which allowed them to just as easily

pull up the application on their own mobile devices. Scan the QR code

on this article to try it out!

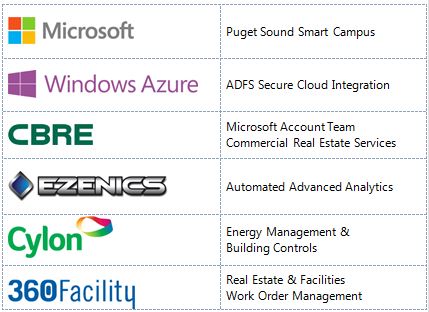

Personnel from Ezenics and demo integration partners from Microsoft,

CBRE, Cylon, and 360 Facility were available for demonstrations, but

much of the conversation surrounding the displays emerged organically

as conference-goers were excited to use the application and discuss the

benefits of being able to deliver the power of enterprise-level

analytics integrated with most work order management and control

systems to every field technician, not to mention further supporting

and empowering them with prescribed solutions to common issues,

downloadable manuals, detailed asset information, floorplans, location

detection via GPS, and demand response live event notifications.

The Ezenics Mobile integrated solution allows technicians to

effectively slash the time that it takes to locate, examine, and

service a machine; respond to calls; and complete work orders to a

fraction of what it would take using more traditional methods by giving

them all of the information and tools that they need to get the job

done in one interface, regardless of which and how many different

systems their organization employs. For facility and service managers,

the increased productivity of their staff means that more is getting

done in the same amount of time, and that leads to significantly

increased savings and client satisfaction.

The Ezenics Mobile integrated solution allows technicians to

effectively slash the time that it takes to locate, examine, and

service a machine; respond to calls; and complete work orders to a

fraction of what it would take using more traditional methods by giving

them all of the information and tools that they need to get the job

done in one interface, regardless of which and how many different

systems their organization employs. For facility and service managers,

the increased productivity of their staff means that more is getting

done in the same amount of time, and that leads to significantly

increased savings and client satisfaction.

Example Demonstration

At the conference, a few example scenarios were demonstrated to

illustrate how the solution is used and implemented. One of the

scenarios was that of an uncomfortably cold office worker and a

newly-hired service technician:

At the conference, a few example scenarios were demonstrated to

illustrate how the solution is used and implemented. One of the

scenarios was that of an uncomfortably cold office worker and a

newly-hired service technician:

“Sue” is an office worker on the Microsoft Smart Campus, and

“Matt” is a brand-new CBRE service technician. For this scenario,

Ezenics is providing the integrated analytics and asset management, 360

Facility is providing the integrated work order management system, and

Cylon is providing FDD-ready controllers, which enabled rapid,

low-cost, “plug-n-play” integration with the Ezenics AFDDI™.

Sue arrives very early to prepare a meeting room and realizes that it’s

uncomfortably cold, so she asks the secretary if anything can be done

to warm up the space. The secretary makes a quick call to the facility

management call center at CBRE, and they raise the temperature setpoint

from 74°F to 80°F. After half an hour, Sue is still cold, and her

meeting is soon to take place, so she again alerts the secretary. In

response to the heightened priority of resolving the issue before the

meeting, CBRE quickly dispatches Matt to the building, smartphone in

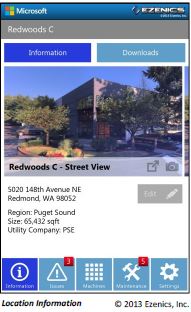

hand. Arriving at the location, Matt uses the GPS-enabled location

detection feature and is presented with a street view of the building

along with summary information and additional downloadable content such

as floorplans and other available engineering documents.

Sue arrives very early to prepare a meeting room and realizes that it’s

uncomfortably cold, so she asks the secretary if anything can be done

to warm up the space. The secretary makes a quick call to the facility

management call center at CBRE, and they raise the temperature setpoint

from 74°F to 80°F. After half an hour, Sue is still cold, and her

meeting is soon to take place, so she again alerts the secretary. In

response to the heightened priority of resolving the issue before the

meeting, CBRE quickly dispatches Matt to the building, smartphone in

hand. Arriving at the location, Matt uses the GPS-enabled location

detection feature and is presented with a street view of the building

along with summary information and additional downloadable content such

as floorplans and other available engineering documents.

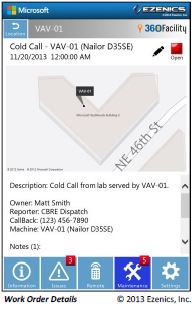

On the first screen, Matt sees a red notification for an open work

order assigned to him for the building via 360 Facility’s integrated

work order system and taps “Maintenance” to bring up the details. Right

away, he can find out which machine the work order is associated with

(VAV-01), the reporter, the call-back number, a description of the

situation, and an image of where the machine is located in the building.

Even

though he is a newly-hired technician who has never even been to the

building, he already has an understanding of the situation, including

the location of the machine responsible for making Sue’s meeting room

too cold.

Matt also notices a red issue notification for the VAV and taps

“Issues” to open a list of faults detected by the integrated Ezenics

Automated Fault Detection, Diagnosis, and Impact™ (AFDDI™) system. With

the Ezenics AFDDI™ diagnosing the issues automatically for him, Matt

has no need to manually diagnose the problem himself. On the Issues

page, he sees that there are a few issues listed on the VAV, including

a “Setpoint Not Met – ZAT – Overcooling” fault and a “Supply Air Damper

Unresponsive – On/Open” fault.

Matt opens the details pages for both faults, which provide him with

full descriptions of the faults, how many times they have occurred,

when they were first detected, the financial impact and severity ranks,

and even a list of engineer-prescribed potential solutions. He finds

that the “Setpoint Not Met – ZAT – Overcooling” fault means that even

though the room is too cold, the machine is still cooling the room even

further, wasting energy and causing a comfort problem. The “Supply Air

Damper Unresponsive – On/Open” fault indicates that the unresponsive

damper is to blame for the problem and needs to be repaired.

Matt opens the details pages for both faults, which provide him with

full descriptions of the faults, how many times they have occurred,

when they were first detected, the financial impact and severity ranks,

and even a list of engineer-prescribed potential solutions. He finds

that the “Setpoint Not Met – ZAT – Overcooling” fault means that even

though the room is too cold, the machine is still cooling the room even

further, wasting energy and causing a comfort problem. The “Supply Air

Damper Unresponsive – On/Open” fault indicates that the unresponsive

damper is to blame for the problem and needs to be repaired.

After finding out what the problems are, Matt taps on “Information” to

learn the VAV’s brand, model, serial number, and any other information

in the asset management system. With this additional information, he

can already determine which parts, tools, and equipment to carry with

him into the building.

Without

prior experience diagnosing this VAV and these issues manually, Matt

already knows what the problems are, how bad they are, potential

solutions for how to fix them, and what he needs to take with him to

repair the VAV before he even leaves his truck.

After the repair is complete, Matt simply scans the QR code on the side

of the machine once again to bring up the diagnostics and BMS access in

order to verify that it is now working properly. He notices that there

is a cooling setpoint exception caused by the previous modification

made by the call center, which if left unchecked would have resulted in

Sue’s meeting room being allowed to drift to 80°F, invariably resulting

in another service call. In order to correct the setpoint and resolve

the exception, Matt simply taps “Remote” and is not only able to view

real time data from the VAV but is also able to set the cooling

setpoint back to its correct value via the secure BMS integration.

Using

the Remote control feature, Matt is able to effect change on the VAV

using his phone and fixes the exception without having to call in or

find another terminal to access the Building Management System.

[an error occurred while processing this directive]

Only one thing is left to do, and that is to complete the work order by

going back to “Maintenance” and changing its status to “Complete”

through the integrated work order management system.

Rather than making multiple trips in and out of the building, spending

time manually diagnosing the issue, and juggling both his work order

system and the BMS, Matt has managed to complete the job using a

single, integrated software tool on his phone in just one trip. The

Ezenics Mobile agnostically integrable solution provides him with an

unprecedented level of support and control, and for Matt, that’s

reduced frustration. For his manager at CBRE, it’s time saved and

another job squeezed in today. For Sue, the conference room will be

comfortable in time for her meeting. For the facility management and

intelligent buildings industry, it’s “REvolutionary”.

Demo Integration Partners

About

Ezenics

Ezenics was founded in Europe in 2004 with offices now also in

the USA, Dubai, and Argentina. Ezenics offers an intelligent enterprise

facility optimization platform that continuously analyzes sensor,

machine, and energy data creating prioritized, actionable information

and intelligent control. For more information about Ezenics, visit the

website at www.ezenics.com or contact b.thompson@ezenics.com.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]