Communicating

Thermostats for Building Retrofit Applications

Communicating

thermostats create a new potential for old HVAC equipment that would

typically be left as-is for the remainder of its useful life.

|

July 2013 |

[an error occurred while processing this directive] |

|

Communicating

Thermostats for Building Retrofit Applications Communicating

thermostats create a new potential for old HVAC equipment that would

typically be left as-is for the remainder of its useful life. |

|

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

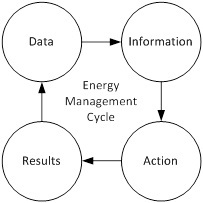

Communication –missing link in the

energy management cycle

As

of 2010, the total U.S. building stock was approximately 275 billion

square feet[1], the vast majority of which is regulated by

thermostats.

Thermostats serve as the most common interface between the occupant and

the building systems that control the comfort in the space. Data

from thermostats, when placed in the proper context, can reveal

valuable information and insight to a facilities manager. Data such

as space temperature and setpoint can be manipulated into informative

alerts, prompting the facilities staff to take proper actions to yield

tangible energy and cost savings. Data from the results can be used to

close the loop in the BEMS process, creating a self-adaptive process

that helps to optimize HVAC equipment operating sequences.

A truly closed loop energy management system is rarely seen in the built environment, primarily due to the lack of infrastructure in place to collect and transmit data. Many facilities managers perform actions based on their experience and working knowledge of the mechanical equipment in their building. These actions such as adjusting the drive speed on a pump motor or changing the hot water supply temperature setpoint might yield the desired result, but they are usually reactionary changes caused by complaints from building occupants. Local space temperature and comfort data can allow facilities staff to make informed decisions and take a proactive approach to facilities management.

So how can this critical data get acquired in an existing building with occupants, obsolete HVAC equipment and a limited budget? It is not economically feasible to wire existing thermostats to a new centralized building energy management system (BEMS). What about spaces without any thermostatic control? It is prohibitively expensive and disruptive to wire new remote thermostats to existing HVAC terminal devices. Furthermore, older terminal HVAC devices installed prior to the onset of solid state electronics will require either a line voltage thermostat or an additional high voltage relay for proper control.

“Communicating” thermostats is a new term for an old device that performs the same primary function as it did 50 years ago. The critical difference is that unlike traditional thermostats, communicating thermostats can wirelessly send, receive and relay information to other devices. Several manufacturers make battery-powered or self-powered communicating thermostats, creating a completely wireless “peel-and-stick” solution for spaces without an existing remote thermostat. This technology provides a low-cost way to transmit vital data to facilities managers, filling in the missing link in the energy management cycle.

New Potential for Old Equipment

Communicating

thermostats create a new potential for old HVAC equipment

that would typically be left as-is for the remainder of its useful

life. This potential can be realized as an affordable, manageable and

scalable retrofit solution for buildings currently without a BEMS or

automation system.

Affordable

Labor typically accounts for 50% or more of the total project cost when

installing a new thermostat. The costs and inconvenience of cutting

drywall, snaking wire, patching new drywall, spackling and painting the

wall with primer and finishing paint coats can be avoided with

wireless, communicating thermostats. A wireless solution is also highly

preferred for most building owners and tenants who wish to implement

the most non-invasive solution possible.

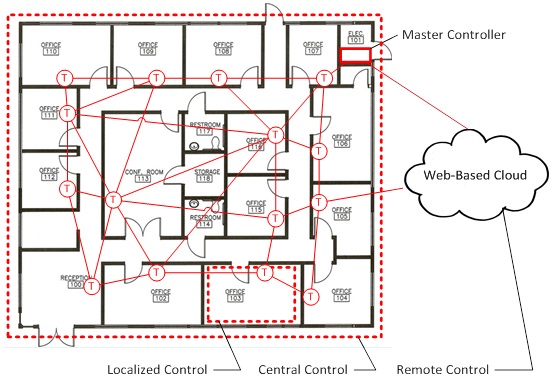

Manageable

A communicating thermostat can be managed locally in its respective

building zone, centrally on a master controller as part of a BEMS or

remotely over the internet via a webpage front end. The versatility of

this technology allows for easy and convenient system management from

any location with an internet connection.

Scalable

Communicating thermostats serve as a highly scalable solution due to

their fast, low-cost installation. A building is not a static, but

rather a dynamic environment with systems that can change dramatically

throughout the building’s lifetime. As building owners renovate,

tenants knock down interior walls, or equipment is replaced, the

heating and cooling loads in each space will change. Scalable solutions

are highly advantageous in this type of dynamic environment. Once the

BEMS backbone is in place, additional communicating thermostats can be

deployed or moved as the needs of the building change. The versatility

of communicating thermostats also allows for a phased deployment,

implementing in strategic clusters throughout the building.

Navigating the Jargon

What makes a “communicating” thermostat

a communicating thermostat?

Although communicating thermostats perform the same basic function as a

traditional thermostat, they are inherently different in how they

transmit information. A communicating thermostat has the ability to

wirelessly transmit sensory and control information to other devices.

What’s a transmitter? Is it the same as

a thermostat?

It is important to recognize the distinction between a thermostat and a

transmitter. The key difference is that while the thermostat performs

control logic to send signals to an HVAC end device for temperature

regulation, a transmitter merely sends the temperature data it receives

to a controlling device. There is no embedded logic in a transmitter.

What is a receiver? Is it the same as a

controller?

Similar to the transmitter vs. thermostat distinction, a receiver does

not have any embedded computational logic to control an HVAC end

device. A receiver merely accepts a wireless command signal and

performs a function, typically related to a relay. A controller on the

other hand comes with either pre-programmed or programmable logic to

receive signals, interpret the desired function and pass the desired

output to the end device. Do not get stuck with a device that cannot

perform the function you had intended because you did not realize

receivers are not the same as a controller.

“Wireless” means less wires

The idea of a completely wireless installation is something that

engineers and contractors may fantasize about, but it is often not the

case. Many communicating thermostats that are listed as “wireless” give

the customer the impression that the thermostat is truly a

“peel-and-stick” device that requires no wires or power at the wall.

This is sometimes true. There are battery powered ZigBee and

self-powered Enocean communicating thermostats available that can be

mounted on any indoor surface without wires.

Many “wireless” communicating thermostats are only wireless in the

sense that they can communicate via radio frequency transmission

amongst each other. Most of these thermostats still run on 24 volts and

require low voltage control wire to send signals to HVAC end devices.

This type of “wireless” communicating thermostat is typically

acceptable when replacing an existing thermostat. It is extremely

important to make this distinction when installing a new remote

communicating thermostat in a space without an existing thermostat.

Wireless Data Transmission – Available Technologies

The

advent of communicating thermostats came with new, low-power

methods for data transmission. Enocean and ZigBee are the data

transmission technologies at the heart of the new wave of building

automation devices. Enocean and ZigBee RF transmitters are low-power,

low data transmission devices. These characteristics are well suited

for building automation devices where wiring is critical and large

amounts of data transmission are not typically necessary. Though

different, both technologies have key advantages over conventional data

transmission technologies such as WiFi or Bluetooth.

Table 1 - Wireless communication technologies, comparison table[4]

|

Technology |

Com.

Standard |

Power

Consumption |

Throughput

[Kb/s] |

Range

[ft] |

Frequency |

|

Wifi |

IEEE

802.11 |

High |

10,000 |

30-300 |

2.4

GHz |

|

Bluetooth |

IEEE

802.15.1 |

Medium |

1,000 |

10-30 |

2.4

GHz |

|

Zigbee |

IEEE

802.15.4 |

Very

Low |

250 |

100-300 |

2.4

GHz |

|

Enocean |

ISO/IEC

14543-3-10 |

Self-powered |

125 |

30-100 |

315

or 902 MHz (US) |

The most important advantage over conventional transmission

technologies is the low power consumption associated with both ZigBee

and Enocean. ZigBee devices transmit small data packages over a

periodic rate, allowing ZigABee devices to run on conventional

batteries

capable of lasting several years. Enocean devices transmit at a lower

data rate and consume even less power than ZigBee. Many Enocean devices

are self-powered and capable of harvesting all necessary power for data

transmission from small solar cells or mechanical switches.

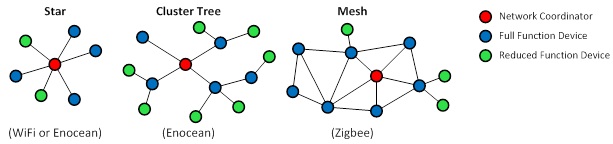

Common Network Geometries

Wireless communication networks have a variety of possible geometries

depending on the functionality of the coordinator and devices. All

signals must be passed through the coordinator for the network to

function properly. The coordinator serves as a single point of failure

for the network, making it extremely important to ensure that the

coordinator can withstand power outages and other contingency events.

Full function devices are capable of passing data though from one

device to another. Reduced function devices can only send and/or

receive signals from one source.

Enocean devices operate as a point-to-point network as shown in the “star” and “cluster tree” configurations above. Signals are routed over a preconfigured pathway to and from the network coordinator. ZigBee devices operate in a self-healing “mesh” network, routing signals to and from the coordinator through any combination of devices along the way. Typically, a signal can pass through up to 5 devices before signal degradation becomes a problem. The mesh geometry is advantageous over the star or cluster-tree geometries because it reduces the number of potential points of failure.

ZigBee Family

There are two families of ZigBee devices found in HVAC control

equipment, ZigBee Pro and ZigBee IP. The ZigBee Pro family consists of

a universal standard, allowing all ZigBee Pro devices to communicate

over the 2.4 GHz bandwidth. ZigBee Pro Green, a self-powered version of

ZigBee Pro is now available in limited applications. The ZigBee IP

family is a collection of proprietary communication protocols, specific

to each manufacturer. Typically, ZigBee IP devices must be made by the

same manufacturer to communicate. For more information, please refer to

the ZigBee Alliance[2]: http://www.zigbee.org/.

Enocean Alliance

The Enocean Alliance consists of a group of OEMs and distributors who

promote and sell Enocean devices. A variety of wireless, self-powered

equipment including switches, sensors, controllers, receivers and

gateways are provided on the alliance webpage, along with product

documentation and links. For more information, please refer to the

Enocean Alliance[3]: http://www.enocean-alliance.org/en/home/.

Major equipment manufacturers

Table 2 - Enocean and Zigbee communicating thermostats – sample of available products as of June 2013

|

MFR |

Model |

Communication |

Control |

Power |

|

Ilumra [5] |

Enocean 315 MHz |

Enocean 315 MHz |

Self-Powered |

|

|

Thermokon [6] |

Enocean 315 MHz |

Enocean 315 MHz |

Self-Powered |

|

|

Distech [7] |

Enocean 315 MHz |

Enocean 315 MHz |

Self-Powered |

|

|

EchoFlex

[8] |

Enocean 315 MHz |

Enocean 315 MHz |

Self-Powered |

|

|

KMC [9] |

Enocean 315 MHz |

Enocean 315 MHz |

Self-Powered |

|

|

Siemens [10] |

Enocean 315 MHz |

Enocean 315 MHz |

Self-Powered |

|

|

WiSuite [11] |

Zigbee IP |

Zigbee IP |

Battery |

|

|

Verve [12] |

Enocean 315 MHz |

Wired Line Voltage |

Wired |

|

|

Schneider Electric [13] |

Zigbee Pro |

Wired Line Voltage |

Wired |

|

|

Greenologic/4-noks [14] |

Zigbee IP |

Zigbee IP |

Battery |

|

|

Honeywell [15] |

Zigbee Pro |

Zigbee Pro |

Battery |

|

|

Enernet [16] |

Proprietary 900 MHz |

Zigbee IP |

Battery |

|

|

Telkonet [17] |

Zigbee IP |

Zigbee IP |

Battery |

|

|

Viconics [18] |

Zigbee Pro |

Wired 24 VAC |

Wired |

Table 3 - Enocean and Zigbee gateways - sample of available products as of June 2013

|

FR |

Model |

Input |

Output |

Bidirectional |

|

Thermokon [6] |

Enocean 315 MHz |

LONworks |

unknown |

|

|

Thermokon [6] |

Enocean 315 MHz |

BACnet IP |

unknown |

|

|

Schneider Electric [13] |

MPM-GW2 |

Enocean 315 MHz |

Zigbee Pro |

Yes |

|

Viconics [18] |

Zigbee Pro |

BACnet IP |

unknown |

|

|

Schneider Electric [13] |

Zigbee Pro |

BACnet IP |

unknown |

Design Considerations

Understand your project scope

It is important to understand the overall purpose when implementing

communicating thermostats. Identify the parties that will be managing

these thermostats and whether the thermostats will be managed locally,

centrally across the building or remotely over the internet. Once the

purpose is established, identify the I/O points (if any) that will

comprise the BEMS. How will these I/O points be transmitted between the

communicating thermostat and the central management system? Will

bidirectional data transmission be required? If so, the communicating

thermostat and gateway equipment must be selected accordingly. Is the

BEMS going to integrate with other control systems in the central

plant? If so, the gateway will likely have to convert thermostat I/O

points into a conventional protocol such as BACnet, Modbus or LONworks.

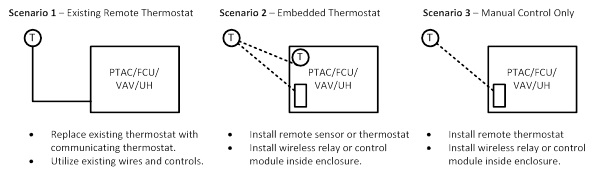

Additionally, it is important to understand the existing conditions within each space to be controlled. There are an infinite number of potential existing conditions, however many can be categorized into one of the three conditions below:

Equipment limitations

Before developing detailed engineering plans and specifications, it is

a good idea to verify wireless transmission ranges in the field with a

signal strength indicator. Ranges provided in manufacturer

specifications are general guidelines and vary substantially from

building to building. Metallic surfaces such as metal studs, elevators,

or decorative hallway finishes can partially or completely block signal

from passing through, so field verification is extremely important.

Another important consideration is how each device will be powered,

especially in the built environment where additional wires and

electrical raceways are not always acceptable. Providing power,

configuring communications between each thermostat, end device and

gateway quickly add labor costs to the BEMS. All of these factors must

be considered when budgeting for a project, laying out floor plans and

selecting equipment.

When selecting equipment, is it critical to understand the operating sequence of each HVAC end device and how the device will be controlled with your communicating thermostat. Understand which piece of equipment will house the control logic in the operating sequence. If a relay is only configured to communicate with a specific thermostat or temperature sensor, make sure that the sensor has the control logic, either pre-programmed or programmable, to carry out the proper operating sequence.

[an error occurred while processing this directive]

Industry trends and projections

Communicating thermostats have made substantial advances since their

inception, including gains in wireless range, increased reliability and

battery life improvements. The industry has grown in a unified manner,

allowing for more comprehensive solutions as products become more

compatible with one another. Major manufacturers have joined the party,

most recently noted by Schneider Electric’s acquisition of SCL

Elements, the makers of Can2go in January.

Enocean is in the process transitioning from the original 315 MHz North American frequency to 902 MHz. The new North American frequency is supposed to increase the wireless range by a factor of 2 or 3. Manufacturers are silent on the exactly how improved the new transmission range will be. Expect the new frequency to be available on existing products by Q4 of this year.

ZigBee Pro Green, the first self-powered ZigBee device, is currently available in limited applications such as wall switches. This technology will continue to grow into many of the self-powered applications currently served by Enocean. It will likely be some time before wireless, self-powered ZigBee thermostats are readily available on the market. For more information, please refer to the ZigBee Alliance: http://www.zigbee.org/Specifications/ZigBee/GreenPower.aspx.

Communicating thermostats will continue to grow in sophistication in the coming years. Touch screen user interfaces such as the one made by Nest[19] are becoming more prevalent on high-end thermostats.

References

[1] http://architecture2030.org

[2] http://www.zigbee.org/

[3] http://www.enocean-alliance.org/en/home/

[4]

http://www.csr.com/sites/default/files/white-papers/comparisons_between_low_power_wireless_technologies.pdf

[5] http://www.illumra.com/

[6]

http://www.thermokon.de/EN/thermokon-sensortechnik-14/start.html

[7] http://www.distech-controls.com/

[8] http://echoflexsolutions.com/

[9] http://www.kmccontrols.com/

[10] http://w3.usa.siemens.com/BUILDINGTECHNOLOGIES/US/EN/

[11] http://wisuite.com/

[12] http://www.vervelivingsystems.com/

[13] http://www.schneider-electric.com/site/home/index.cfm/us/

[14] http://www.greenologic.co.uk/

[15] http://honeywell.com/Pages/Home.aspx

[16] http://enernetcorp.com/

[17] http://www.telkonet.com/home/

[18] http://www.viconics.com/

[19] http://nest.com/

About the Author

Casey Birmingham, Project Manager – The Falcon Group

Mr. Birmingham is a Project Manager with the Energy/MEP division at the

Falcon Group, specializing in energy audits, energy monitoring and

visualization and building operations.

He has designed and installed a low-cost energy monitoring

and visualization system for the Falcon Group’s Headquarters office in

Bridgewater, NJ. The system tabulates minute by minute electric and

natural gas data and provides results and recommendations based on

weather-correcting factors.

Mr. Birmingham and the Energy/MEP division have led a variety of EERE

building retrofit projects over the past year months, including the

conceptualization and design of a building energy management system

(BEMS) as part of the New Jersey Pay for Performance program. The BEMS

will utilize data from communicating thermostats for optimized control

of the building’s boilers, chiller and VFD drives. When complete, the

project will reduce the building’s site energy consumption by over 40%,

saving over $380,000 in annual operations costs.

He is a graduate of Northeastern University and holds a

Bachelor’s Degree in Mechanical Engineering. He currently holds

his Engineer in Training (EIT) certificate and is pursuing a

professional engineering license. He is a member of the American

Society of Heating Refrigeration and Air Conditioning Engineering

(ASHRAE). He has completed coursework provided by ASHRAE in both

HVAC and HVAC controls. This is Mr. Birmingham’s first contribution to

AutomatedBuildings.com.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]