Trends in plug load monitoring and management

Kevin Callahan and Kevin Clinger

Alerton

|

July 2016 |

[an error occurred while processing this directive] |

| Plugged In Trends in plug load monitoring and management |

Kevin Callahan and Kevin Clinger Alerton |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

Building

owners and operators have two primary reasons to monitor and manage

plug loads – one obvious, and the other less so, but also important.

Simply put, these two reasons are: 1) energy efficiency, and 2)

reliable operations.

Let’s look at each of these, in turn, followed by the current

state-of-the-art in plug load monitoring and management tools.

Energy efficiency

Equipment

plugged into wall outlets represents an ever larger share of energy

consumption in buildings, so naturally building pros are looking there

for energy savings. Plug loads now consume about 15% - 20% of

electricity in offices, and as much as 40% - 60% in some buildings,

reports the New Buildings Institute. A double whammy of trends is

causing this. First, as building envelopes and HVAC systems become more

energy efficient, plug loads naturally account for a larger piece of

the pie. Second is the explosion in the number and types of office

equipment.

Much of plug load consumption is necessary for business operations,

while other draws are wasteful. Think of the difference between

employees using desktop computers during their shifts to complete work

versus leaving monitors on overnight when no one is around. Or, the

employee with a contraband space heater tucked under his desk – not

only drawing power but potentially creating a fire hazard.

With the advent of plug load monitoring and management tools, building

pros have more powerful and sophisticated ways to reduce such phantom

power draws. They no longer have to rely on company memos nagging

employees to shut down equipment at the end of their shifts, or

stickers exhorting them to “turn it off when not in use” plastered on

everything. Instead, equipment can now be turned down or off remotely

and automatically.

Reliable operations

While

reducing electricity waste is a clear benefit of plug load monitoring

and management, an equally beneficial function is ensuring crucial

equipment stays on. So, while facility managers want to make sure an

employee’s desk light isn’t left on all night, they also have an

interest in ensuring that certain equipment stays on. An obvious

example is that power is not cut to mission critical computer servers

or to lab or hospital equipment. A less obvious example is that the

vending machine in the employee break room remains on. While keeping

the Klondike Bars in the office vending machine frozen is not a matter

of life or death, losing power to such a machine can result in costly

waste and a time consuming mess.

Plug load monitoring and management

tools

Today’s

plug load monitoring and management tools help building pros fulfill

both of the above needs. Simple-to-install BACnet-enabled receptacles

interface with building management systems (BMS) to help reduce plug

load costs up to 40%, while ensuring mission critical and other

equipment remains on.

For example, Alerton offers through its dealer network a suite of plug

load tools from Ibis Networks. Such tools provide real-time data on

plug-load energy use, which helps building pros spot excessive power

draws. In the case of the Ibis sockets, as BACnet devices, BMS

operators can easily bring them into Alerton Compass software to be

managed alongside HVAC, lighting and other building systems.

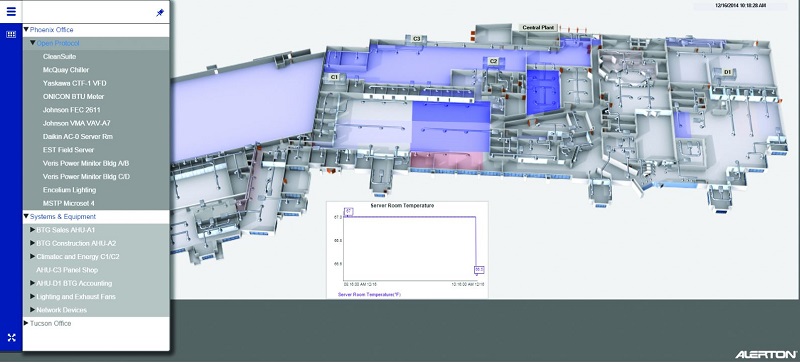

Facility pros can

monitor and manage electrical plugs, along with HVAC, lighting and

other building systems via BMS tools such as Alerton Compass software.

Using these tools, building managers can schedule

selective shutdowns

to individual plugs, while leaving power on for critical equipment in

the same room. For example, shutting down desk lamps in a laboratory

overnight, while retaining power to incubators.

Facility managers also can use plug load monitoring tools to predict

potential equipment failures and take preventative action. A case in

point is a server that starts using higher-than-typical power, which

could indicate the equipment will soon breakdown. By avoiding run to

failure with the server, the facility pros can help avoid costly

disruptions.

About the Authors

Kevin Callahan is a product owner and

evangelist for Alerton, Lynwood, Wash., a Honeywell business

specializing in building management systems. He has 39 years of

experience in the building control technologies field, including

control systems design and commissioning, facilities management and

user training. Callahan can be contacted at kevin.callahan@alerton.com.

Kevin

Clinger is a senior manager of customer marketing for Alerton, with

more than 11 years of experience in various aspects of building

automation systems. He led Alerton’s efforts to bring the Ibis Networks

plug load monitoring solution to Alerton dealers. Clinger can be

contacted at kevin.clinger@alerton.com

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]