|

June 2013

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

|

Modeling Building Automation and

Control Systems

Enrich the data with

digital relationships within the building, coordinate it with other

designers and finally populate our facility management systems.

|

Jim

Sinopoli PE, LEED BD+C, RCCD

Managing

Principal,

Smart

Buildings LLC

Contributing Editor

|

Many building owners

and facility managers lack good documentation for

their automation control systems. Documentation has value; lack of

system documentation can cost an organization and will increase risk.

Lack of documentation means troubleshooting and work orders take

longer, are more expensive and it extends the time it takes to resolve

issues for tenants or occupants. It also may mean preventative

maintenance isn’t done because you don’t know what the PM schedule is,

possibly shortening the life of the equipment. Or it may mean that

facility personnel really do know a lot about their systems but if they

move to another organization or company or retire, all that knowledge

or “system documentation” leaves with them.

This

lack of documentation for automation and control systems is caused

by inadequate organization and planning in the handoff from

construction to building operations and the fact that much of the

documentation is in a paper format.

Help is on its

way. The buildingSMART alliance with the input of the US

Army Corps of Engineers has developed and proposed a data structure for

representing information related to automation and controls. It falls

under a large umbrella called Building Information Modeling or BIM.

BIM

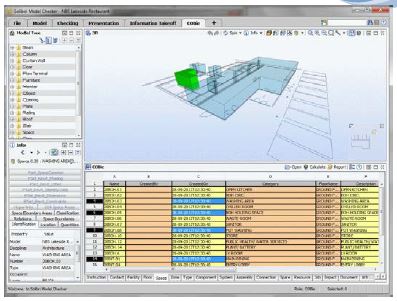

If you’ve had any

involvement in new building design and construction

you’re probably familiar with BIM. You may be aware or exposed to the

3-D modeling of a building and its components and understand the value

it can provide in avoiding potential “collisions” between the designs

created by different engineers. Likewise, the usefulness this modeling

can provide to contractors in fabricating building systems and

components. Major designers and construction companies have embraced

BIM and rightfully so; it can reduce change orders, assist in

maintaining schedules and generally produce better buildings.

The larger picture and

the utilization of BIM should be an approach of

a life-cycle asset management tool. Such a tool is used in creating and

acquiring data during design and construction which is then delivered

to facility management. It’s the building operations that will be 85 to

95 percent of a building’s lifecycle.

The larger picture and

the utilization of BIM should be an approach of

a life-cycle asset management tool. Such a tool is used in creating and

acquiring data during design and construction which is then delivered

to facility management. It’s the building operations that will be 85 to

95 percent of a building’s lifecycle.

To facilitate the

exchange of information from design and construction to building

operation, a standard called Construction Operations Building

Information Exchange (COBie) was developed by a laboratory of the US

Army Corps of Engineers.

COBie is a format

of data for building assets. It’s associated with BIM, but doesn’t

involve spatial modeling. It is part of the National Building

Information Model. COBie may include data such as preventative

maintenance schedules, model numbers, warranty information, product

data sheets, and everything needed to operate and maintain the

particular asset.

Industry

Foundation Class (IFC)

The modeling of

automation systems involves the development of a specific IFC for

automation and control systems. An IFC is an open and neutral data

model that describes building and construction industry data to

facilitate interoperability of the data between designers, contractors

and facility management. The IFC model specification is registered by

the International Organization for Standardization (ISO) and is an

official International Standard (ISO 16739:2013). The effort is

referred to as Building Automation Modeling Information Exchange or

BAMie.

The proposed IFC

for the Buildings Controls Domain has core entities to represent

automation and control systems. During the design phase, when different

design elements are being determined, the data exchange between

automation and control systems can be coordinated with other design

elements. The proposed domain models for automation systems are

controllers, sensors, actuators, alarms and instruments, and control

elements that have integrated panels and indicators. The model

definitions are organized into addresses, configurations, connections,

performance and components and types.

- Connections - The

model definition of “connections” has logical and

physical connections. The “IfcRelationship entity” can then model the

connections. Inputs and outputs for devices such as controllers,

actuators, thermostats and sensors can be mapped.

- Components and Types

– Initially design components may be generic

but at some stage of a project specific product data is needed and a

product template can be used to organize the data. In this case an

“IfcType Object” entity may be used to acquire product specifications

and “IfcDocument References” can used to provide links to installation

and O&M manuals.

- Addresses – This

model definition provides an addressing format for

specific data points. It also seems like an area where Project Haystack

could add some value. Project Haystack is an open source initiative

that has developed naming conventions and taxonomies for building

equipment and operational data. Standardizing addressing formats and

“binding” addresses of data points to other objects in a building or

buildings facilitates integration of the data and enriches the context

of the data point by incorporating related data.

- Configuration – BAMie

is ambitious in documenting automation and

control system configurations. The idea is to make the information

exchange between the system contractor, other designers, contractors

and the facility manager or building owner more efficient.

Configuration data can include data such as set points for specific

building spaces, schedules, even alarm conditions. The usefulness of

documenting system configurations for information exchange may depend

on the specific automation and control system, specifically the

management workstations of the system, where configurations can be set.

- Performance – The

proposed model definition for performance is

interesting. Because BAMie data includes relationships between objects

and artifacts and can produce a fluent exchange of data, it can

facilitate the creation of performance metrics that an automation and

control system would not be able to do, for example creating 3D models

or color coded floor plans of energy consumption trends over a time

series.

[an error occurred while processing this directive]The

building automation industry is abuzz with “data analytics”.

Analytic software solutions for complex HVAC systems have shown

substantial benefits in operations and energy management. The key is

data. The proposed BAMie is not only a repository for comprehensive

data in automation and control systems, but it provides a means that

the data can be easily exchanged with other systems and other various

colleagues involved in design, construction and operation of the

building.

The building

automation industry needs to embrace and support the BAMie

effort. Construction Directors and Facility Managers should request

designers and contractors provide system data and submittals in

electronic format.

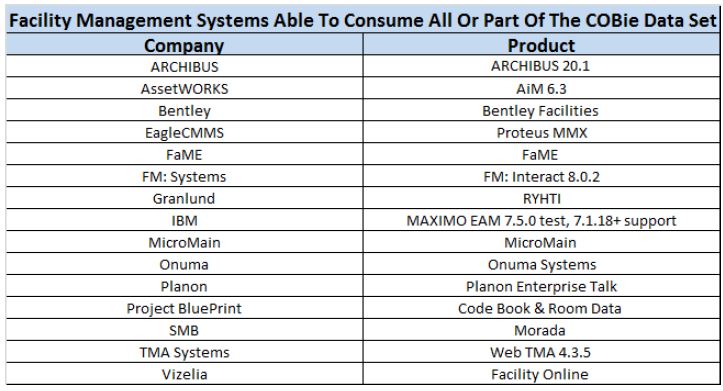

Finally, the

industry experience with BIM and information exchange to

date is somewhat isolated to just architects, design engineers and

construction companies. Not many facility management organizations have

consumed and used BIM data despite the fact that the greatest benefits

of BIM are in building operations. There are a number of facility

management systems that can import BIM and populate FM applications

such as asset management, preventative maintenance and document

management.

If we can acquire

automation and control system data digitally in the

proposed format from the start of a project, enrich the data with

digital relationships within the building, coordinate it with other

designers and finally populate our facility management systems, we will

be on the road to better building performance.

For more

information, write us at info@smart-buildings.com .

Photos courtesy of Google and Bing Images

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]