|

June 2016 |

[an error occurred while processing this directive] |

| Making your plant room a

value-generating asset Typically hidden away in plant rooms, HVAC systems can be complex, challenging and are frequently overlooked. |

Chirayu Shah, General Manager, Conserve It |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

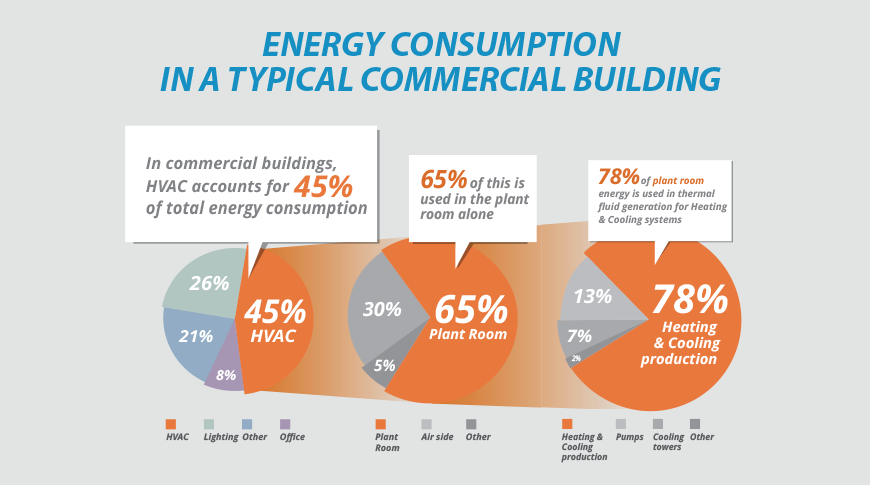

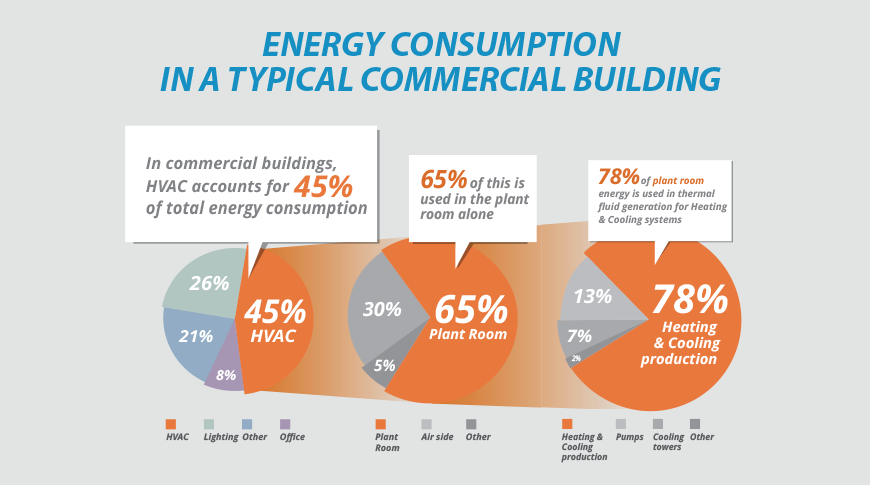

In

commercial buildings, HVAC is by far the most energy intensive system,

accounting for close to half of the total energy consumption.

For this reason every efficiency improvement in HVAC performance can

significantly reduce the energy profile of the building, turning HVAC

optimisation into a value-generating opportunity.

Typically hidden away in plant rooms, HVAC systems can be complex,

challenging and are frequently overlooked. No wonder that energy saving

opportunities are missed in this complex technical arena.

Dedicated, specialised control solutions are required to manage HVAC

systems correctly and efficiently. By optimising the operation and

maintenance of these systems, it is indeed possible to capture the true

energy reduction potential available and to manage this over time.

The Plant Room

The plant room can be considered the heart of the HVAC systems within

any building. It is typically where hot and cold water is created for

distribution to other HVAC subsystems throughout the building.

Typical HVAC equipment in plant rooms include; chillers, heat pumps and

boilers; heat rejection systems: air, water, ground source; and

distribution equipment: pumps, valves and pipework.

Chillers and heat pumps are the heaviest energy using components,

accounting for 78% of total plant room energy consumption. Optimisation

of the energy used within the plant room is therefore critical to the

overall building energy profile, and can only be effectively managed by

suitably experienced technical experts.

Solutions

Excellent system design and the use of high quality components are

essential. However, without accurate monitoring & verification

along with continuous commissioning, even the best HVAC systems degrade

over time.

Developed with an in-depth understanding of all thermodynamic variables

involved in managing plant room HVAC equipment, PlantPRO is one such

solution, enabling optimum control of every device with its integration

into a single synergistic system.

[an error occurred while processing this directive]Optimisation

is not achieved by the use of a single algorithm designed to ensure the

best efficiency, but is rather a continuous process articulated through

different levels of smart software functions, which contribute to

ensure the best result.

The optimisation process can be represented by a pyramid divided into

several layers, the base of which corresponds to the initial design

phase of HVAC systems by consultant Engineers.

Every project presents specific challenges. Designing the optimum

system for each HVAC application and selecting the best plant room

equipment, is the essential starting point and is also the key

responsibility of the M&E Engineering consultant.

In order to achieve and maintain the high level of efficiency as per

original design, optimised management of the plant room is essential.

Every single element of the system involved in the production and the

distribution of the energy must therefore operate in perfect harmony.

For this reason it is essential to use a dedicated optimisation &

control software system which includes high-end logic, to ensure real

energy savings as well as delivering long term reliability.

PlantPRO is award-winning Plant room

optimisation and control software developed by Australian company

Conserve It. For more information visit www.plantpro.com.au

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]