March 2006

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

March 2006 |

[an error occurred while processing this directive] |

|

PART 1: WHY PID CONTROL IS OUTDATED FOR MODERN BUILDING APPLICATIONS |

Thomas

Hartman, P E A Three Part Series |

PART 2: An Introduction to Relational Control - April 2006

PART 3: Process Change Required For Effective Relational Control - May 2006

The really exciting things about the current rapid growth and advances in building control networks are all the control functions they could do but don’t … yet. Digital controls are already the basis of nearly all controls installed in buildings today, but despite the enormous emphasis on building control networks, they continue to be one of the most underutilized systems anywhere. Why? Because the fundamental control methodologies for HVAC control are nearly the same as those developed at the time automatic building controls were first introduced early in the last century - long before control networks had been conceived.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

The result is that control applied in many building comfort systems today consists primarily of independent “PID” (Proportional, Integral and Derivative) control loops. The rapidly developing network capabilities are largely unused for direct control purposes. Over the last several decades building systems have made significant advances in sophistication, and controls have evolved into digital networked systems. Continued use of primitive stand alone PID control techniques seriously undermines the performance, stability, efficiency and reliability of these modern building comfort systems. But by shifting to a new paradigm and focusing design and development efforts on the networking capabilities of modern control systems, it is possible to conceive and employ system design and control concepts that open new vistas for building system performance. Unprecedented improvements in energy efficiency and comfort await such initiatives. This three part series will try to explain how and why the industry will benefit by moving ahead to better performing and significantly more efficient systems by replacing conventional PID based HVAC system design and control strategies with emerging Relational Control approaches.

WHAT’S WRONG WITH PID CONTROL?

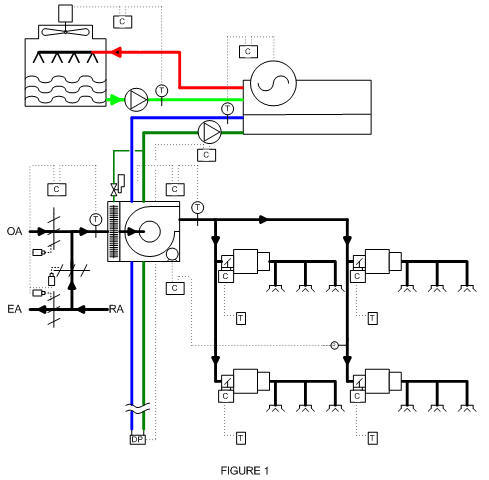

For about as long as building controls have been in existence, control theory has been focused on a single input, single output proportional based control model, and this continues for many to be viewed as the model for modulating capacity or flow for the various controlled devices and variables that make up a modern HVAC system. In this method of modulating control, there is one controlled variable (typically a temperature or pressure point), and one controlled device (valve, damper, motor speed, etc.) in each control loop that is modulated to maintain the controlled variable at a specific value (setpoint) using a feedback circuit to compensate for changes in external conditions. A schematic for the application of this classical proportional control model to a typical HVAC system is shown in Figure 1.

For most of the last century, the controller modules labeled “C” in Figure 1 were pneumatic or electric analog proportional control devices but with the advent of digital controls, these controllers have become software modules embedded in larger DDC (direct digital control) control panels with added integral and derivative gains to become what are now called “PID” control modules.

Today, although control is provided with digital control panels and networks as shown in Figure 2, the independent and stand alone nature of each PID control loop continues to be integrated into both equipment and control designs. So, although a network now connects these DDC panels and each PID controller has sophisticated features that provide much greater flexibility, most systems still operate as shown in Figure 1. There are fundamental problems with this control architecture. These problems cannot be solved simply by developing more robust PID controller modules or applying network based setpoint reset regimens. The most serious of these problems associated with the continued use of PID for control in HVAC applications are:

1. Inefficient System Operation: With the focus of modern HVAC systems now on optimizing energy efficiency, PID based control is an inherently inefficient method of control for several reasons. The new system optimization theory for the present era of variable speed equipment is based on the Equal Marginal Performance Principle. This principle demonstrates very clearly that the temperature and pressure outputs controlled in typical PID control loops are not directly related to energy optimization. So, routines that attempt to adjust these setpoints for energy optimization are unnecessarily cumbersome, often ineffective, and sometimes detract from the ability of the system to operate effectively and with acceptable control stability. For these reasons, setpoint optimization software overlays frequently fail to meet performance expectations and operators often override or discontinue such setpoint reset features to improve control stability or to mitigate performance shortcomings. Furthermore, nearly any system to which PID is applied as the basic control structure requires a compromise in energy efficiency for the sake of maintaining stable control. As an example, for stable operation and adequate controllability, control valves used in PID control loops are recommended to be undersized such that ¼ to ½ of the total distribution system pressure head requirement is developed across the control valves at full flow conditions. These resulting high control valve pressure losses adversely affect the system energy consumption under all operating load conditions.

2. Inadequate Coordination: The purpose of building HVAC systems is to maintain comfortable spaces and provide good indoor air quality. A second serious problem with PID control in modern systems is that it is not effective in coordinating the operation of the various system components as a system to ensure system comfort performance is maintained. In modern VAV air systems, as shown in Figures 1 and 2, chilled water temperature, distribution pressure, supply air temperature and duct static pressure setpoints are typically maintained with stand alone PID controls that may be reset for optimization. However, if some of the spaces served are not able to obtain sufficient cooling, systems do not effectively readjust these setpoints in a coordinated fashion to ensure additional cooling is provided to those spaces. As a result it is not at all unusual to find systems that are struggling to meet conditions at the zone level but have unused capacity at one or more of the plant levels. Loss of chiller plant cooling capacity from what is commonly called low delta T syndrome is an example of this lack of coordinated control function.

[an error occurred while processing this directive] WHAT’S THE REMEDY?

The shortcomings of current HVAC system design practices that are based on conventional PID control have largely been ignored because it is incorrectly believed there is little from a technology standpoint that can be done to improve them. Controls specialists have generally tried to mitigate these problems by making PID control loops more flexible with variable gains and automatic tuning functions, and by providing easily programmed setpoint reset features. These enhancements have not scratched the surface of the true energy and system performance improvements shown to be possible with really effective networked controls.

To capture these potential improvements, a whole new network based approach to system control has been developed called “Relational Control.” Success with Relational Control is difficult to achieve when designers try to move forward incrementally from PID control strategies. That may be the reason our industry has been more or less locked in place with conventional PID controls – a barrier similar to what leads to “paradigm paralysis” in business management circles. To be successful with Relational Control, the most straightforward path is to develop an understanding of what this new control is, and then disconnecting one’s self entirely from the current outdated practice of designing systems and controls around stand alone PID operations.

With the advent of variable speed operation and network control capabilities, a new paradigm in HVAC system design and operation has emerged. Whereas previously, many HVAC components yield best operating efficiencies at full load conditions, variable speed components provide maximum operating efficiency at partially loaded conditions. Conventional PID control has generally not been successful in this new arena because it is focused on controlling variables that are not directly related to the performance or energy efficiency goals of the system. In the next part of this series, I will offer a new vision of what effective controls in the digital network era should look like and how they can be assembled to operate most effectively. Please stay tuned!

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]