Will Reduce Barriers and Open Doors for Building Automation Products in the Industrial Internet of Things

Bob Dolin,

CTO,

Echelon Corp.

|

March 2014 |

[an error occurred while processing this directive] |

|

Multiprotocol, Multimedia Solutions

Will Reduce Barriers and Open Doors for Building Automation Products in the Industrial Internet of Things

|

Bob Dolin, CTO, Echelon Corp. |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

Overview

The emerging Industrial Internet of Things (IIoT) represents the next

generation of control networks for building automation. But unlike the

consumer Internet of Things, the IIoT isn’t starting from scratch. The

hundreds of millions of building automation devices already operating

on networks, using a plethora of protocols and both wired and wireless

media, must be stitched together—easily and cost-effectively.

Echelon is focusing on multiprotocol, multimedia solutions that enable

interconnection and intercommunication among currently disparate

building automation networks. These IIoT-based solutions will not only

break down silos between various building automation systems, but the

use of a common IP infrastructure will also open new market

opportunities for device makers and help increase revenues through

streamlined inventory management.

The Need to Bring Devices and

Device Networks Together

Building automation systems today face similar challenges as those

faced by computer networking in the 1980s. Back then, competing

computer-networking systems—from companies such as IBM, DEC, Data

General, and Wang—had developed into a number of large islands. These

separate networks benefited each individual supplier and its customers,

but they made communicating across technologies difficult or impossible.

Looking inside a typical building today, you see air-conditioning

systems that can’t communicate with lighting systems, and security

systems talking yet another language on another network island. Besides

the potential efficiencies that could be gained if disparate building

automation networks could communicate with one another, there’s another

huge reason to overcome protocol and media incompatibilities among

these network islands: the Internet of Things and, more specifically,

the Industrial Internet of Things.

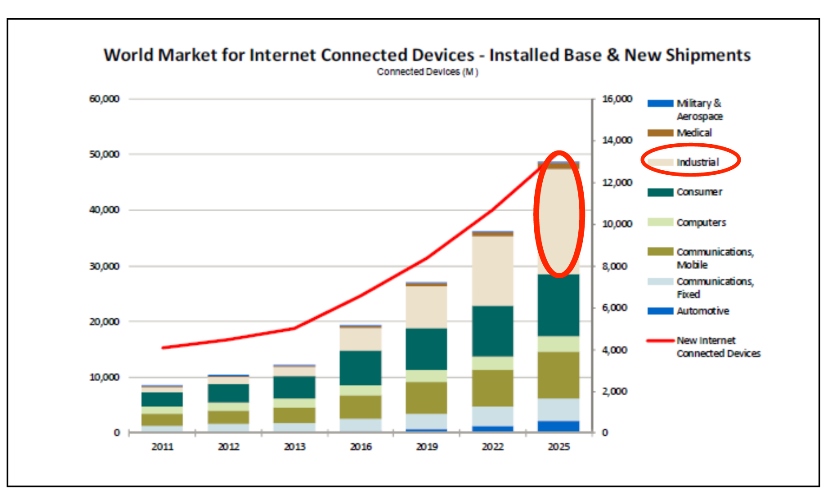

Market researchers such as those at IHS predict

that by 2020, the IoT

will represent almost 40% of all Internet-connected devices; that there

will be a billion industrial and commercial devices installed on the

IoT by 2017; and that the IIoT will add 500 million new units per year.

Those predictions provide tremendous economic incentives to enabling

communications among building automation devices on various networks.

Consumer IoT Solutions Won’t Work in the IIoT

While the IIoT is an important part of the larger IoT story, it’s a big

mistake to equate the consumer IoT—applications such as wearable

fitness trackers or home thermostats—with the Industrial IoT.

Industrial automation today is very sophisticated, and IIoT

requirements are far more stringent than those for the consumer IoT.

IIoT devices often operate in lights-out mission-critical environments,

where they need a certain toughness. For instance, IIoT devices require:

In addition, many IIoT situations do not require—and in fact are not

possible with—interaction with an Internet server or cloud. Unlike the

consumer IoT, the IIoT must include peer-to-peer, autonomous

communities of devices. For response-time reasons, nodes cannot wait to

be granted access to the network by a server, nor can they go through a

lengthy session set-up sequence.

Traditionally, these communities of devices adopted protocols meant to

work specifically for their prescribed operations. In building

automation, the result has been the rise of protocols such as BACnet,

LonTalk, DALI, C-Bus, Modbus, X10, etc.

The Role of IP

The flourishing of the Internet depended on bridging the disparate

networks connecting PCs of the 1980s era. That bridge was IP: Internet

Protocol.

For the IoT and IIoT, IP can also serve as the bridging protocol. More

specifically, it will be IPv6, which will expand the addressing

capabilities of IP to encompass the billions of devices expected to

make up the IoT.

Currently, industrial systems connect to the Internet and internal IP

networks through gateways. These gateways require custom provisioning

and programming to expose the necessary data to the enterprise systems.

Invariably, the gateway constrains what information can pass back and

forth, and its configuration is difficult to evolve to support new

requirements. For control networks in building automation, IP

addressing will move from the gateway to the field bus level, and

gateway functionality—e.g., the translation of data into a common

format—will be integrated onto chips. At the same time, there will be

greater reliance on routers than gateways for connecting networks.

Still, transitioning the billion or so legacy industrial devices will

take more than IPv6. Because IP stops at the addressing and routing of

packets, there will be a need for higher-level protocol services

running on top of IPv4/IPv6 UDP socket interfaces that manage

reliability, security, and device interoperability. That’s where the

multiprotocol IzoT platform for the IIoT comes in.

The Multiprotocol IzoT™ Platform

for the IIoT

The Echelon IzoT platform—available initially as software stacks and

system-on-chip (SoC) offerings—is designed to provide a pathway to the

IIoT for both the installed base of legacy industrial devices and new

devices.

Some of the characteristics and capabilities of the IzoT platform

important for building automation networks include:

The IzoT platform includes technology that simplifies the incorporation

of both existing and new building automation devices and networks into

the IIoT. For example, the decision to base the IzoT stack on UDP

rather than TCP permits the use of multicast and confirmed multicast

messaging so that a single message can simultaneously go to multiple

destinations. As a result, more-constrained nodes can work on slower,

more error-prone links—which allows systems designers to economically

extend IP to the simplest of control nodes.

Above all, however, the IzoT platform is noteworthy for its ability to

provide a full range of industrial-grade capabilities while also

supporting multiple protocols, over a common IP infrastructure, within

a single device or application.

Implications of a Common IP

Infrastructure for the Building Automation Market

[an error occurred while processing this directive]

The ability of both existing and new building automation devices,

running whatever protocols have evolved within their particular

domains, to interoperate with one another is key to extracting optimal

benefit from the IIoT.

Interoperability among currently disparate building automation networks

will not only increase their efficiency, manageability, and

cooperation, it will also improve the overall quality and safety of

building automation systems.

Multiprotocol support has huge implications for the business of

building automation companies. Instead of designing, manufacturing,

supporting, and tracking different unique products for each protocol

option, companies can reduce their number of SKUs (stock keeping units)

when a single device can be configured to support multiple protocols.

Companies can also expand their business. For instance, those that

traditionally have made only LonWorks products can now also compete for

BACnet bids, and vice versa.

At a higher level, then, multiprotocol, multimedia device and

application support over a common IP infrastructure will allow building

automation companies to address new markets and to reap greater

revenues for the same design effort.

About the Author

Robert "Bob" Dolin, Echelon’s system architect, has worked for the

company since 1989. He is the principal or co-inventor of 14 Echelon

patents, and is a designer of the LonWorks protocol, the network

development system environment, the Neuron C programming model, and

LonWorks network management. Before joining Echelon, Dolin spent 11

years at ROLM Corporation, where he was a main developer of its PBX

telephone system Dolin has a B.S. degree in Electrical

Engineering and Computer Science from the University of California at

Berkeley.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]