OT interoperability - the key to intelligent buildings

Chief Commercial Officer

Automated Technology Company (ATC),

Vice President

KNX USA National Group

This article excerpt appears courtesy of KNXtoday.com

|

May 2020 |

[an error occurred while processing this directive] |

| View

from America: OT interoperability - the key to intelligent buildings |

Chief Commercial Officer Automated Technology Company (ATC), Vice President KNX USA National Group This article excerpt appears courtesy of KNXtoday.com |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

'Interoperability is

the ability of two or more systems to interact with each other, whereby

the technical interfaces to each system are completely and

bi-directionally recognised by each other.' This is the pure technical

definition, taken from the Information Technology (IT) or Operational

Technology (OT) perspective. This does not, however, take into account

the human social, economic and organisational interface factors that

also affect system performance.

In the built environment context, OT is the non-business-related

hardware and software that is designed to monitor and/or control

discrete (end) field-devices in one or more building technology

systems, providing multiple building functions, either independently or

in unison.

Streamlining these interfaces to remove the siloed, independent control

communications is the key to making the building intelligent. The aim

is to provide a safe, operationally-efficient supply of energy whilst

at the same time protecting and providing comfort to the areas and

occupants they serve.

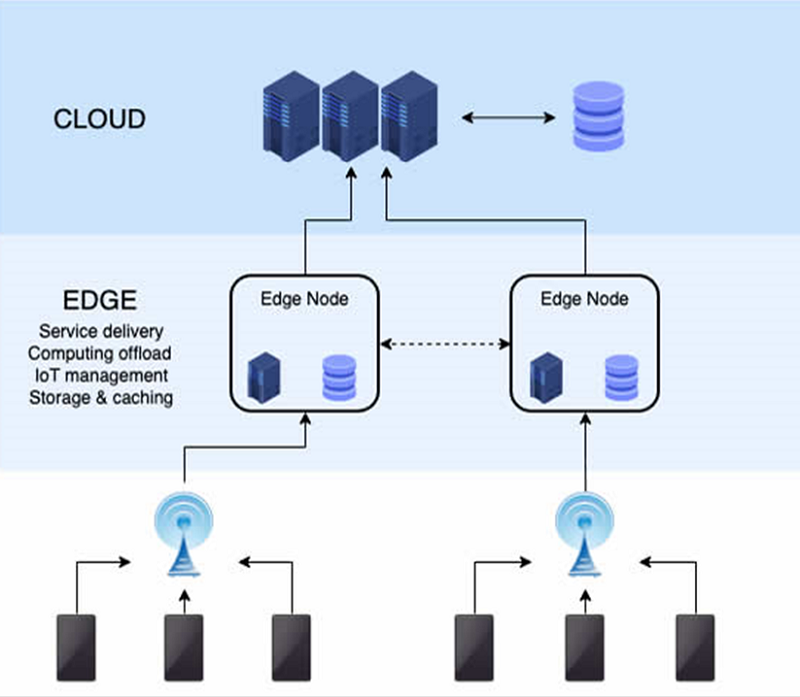

Edge computing

In order to do this, edge computing at the OT level now comes into

play. Edge computing technology acquires, stores, and processes data

and control functions closer to the source of the data, allowing

faster, more secure decision making at the source of the application,

rather than relying on the cloud. The use of edge technology provides

industrial companies with sophisticated features and functionalities

such as interoperability, security of data, low latency, and improved

quality of service [Ref: Frost & Sullivan, Frost Perspectives

article: Edge Computing: A Disruptive Technology for Industrial

Manufacturing dated March 30, 2018] <https://ww2.frost.com/frost-perspectives/edge-computing-a-disruptive-technology-for-industrial-manufacturing/>

Edge computing infrastructure (image

source: By NoMore201 -

Own work, CC BY-SA 4.0, <https://commons.wikimedia.org/w/index.php?curid=82034067>).

This article will focus on the existing technical challenges to

overcome, mainly in the form of the legacy OT infrastructure that is

already in place, such as manufacturer-proprietary systems and

construction trade divisions, coupled with the lightning development of

Apps, IoT and cloud computing. By following some fundamental technical

principles and matching customer applications with global,

open-standard market solutions, we can ensure interoperability is

sustained in the built OT-environment.

The world of open-protocols (image courtesy of Alexander Maier GmbH).

Field level - where the rubber hits the road

As edge computing depends upon field device interoperability, let's

break this down to its root form - the control communication. Not all

open protocols are alike and have fundamental differences regarding

hardware topology and software engineering and programming. BACnet, for

example, makes all HVAC central processes and end-device data points

available on the supervisory (building operator) level to provide

monitoring and, to some extent, field level control. This control,

however, is typically resident in the field hardware i.e. the

controllers, which are programmed with the manufacturer's proprietary

software. This means that, in ‘edge” terms, the source to the

field-level data points is directly through the manufacturer's

field-level controllers, which is localised control that is dependent

upon their proprietary engineering and SCADA (Supervisory Control And

Data Acquisition) software.

Example of a common leisure space in

the hospitality industry

using field-level control (source: JUNG USA).

It's the field interoperability that enables the discrete end-devices

(the more intelligent the better) to operate on an open-communication

level. The aim is to provide logic across the different trade systems

such as electrical distribution, HVAC, LED lighting, daylighting,

access, surveillance, etc, in order to provide intelligent monitoring

and control, completely across your building operation.

That is why the KNX protocol is designed for field-level

interoperability. Both the hardware and software are truly open and

universal - ALL manufacturers follow both a communication (hardware)

and engineering (software) standard rather than each manufacturer using

proprietary programming software.

Trade Automation Level (TAL)

[an error occurred while processing this directive]The Trade Automation Level (TAL) is where central controllers provide

monitoring and control to a specific building system in a central

location, such as a mechanical equipment room (MER). Both HVAC and

electrical distribution are central systems providing air/water and

power to the individual spaces, respectively. An example where central

automation is applied is a central HVAC air-handling unit (AHU) that

distributes treated air to the individual occupant zones. This is the

perfect application for BACnet or Modbus protocols, whereby programming

can be resident either on a dedicated controller or an IP-based

server/controller connected to an overall supervisory SCADA system.

Another example is the main electrical distribution panel (MDP) that

provides protection and control of HVAC equipment, lighting, IT,

electrical receptacles etc. With the MDP, you can build-in intelligence

to monitor the electrical distribution system down to each discrete

load down to the miniature circuit breaker (MCB) level. Typically, the

open protocols used for what is known as the Electrical Distribution

Control System (EDCS) are Modbus, M-Bus or SNMP. The EDCS monitors the

electrical system down to the discrete load level by trending and

identifying anomalies in operation and significantly yielding both

energy and operational savings.

Interoperable Automation Level (IAL)

When combining the data from TAL systems with HVAC and EDCS, you are

able to provide cross-protocol edge computing, making it possible to

have cross-system monitoring, analytics, machine learning and, with

sophisticated algorithms, artificial intelligence across your building

systems. For example, when you combine the HVAC AHU with the electrical

distribution power data, you can provide such simple control strategies

as peak demand limiting via load shedding, prioritisation and strategic

scheduling of equipment, etc. Indeed, you can obtain 20 - 35% energy

reduction, thus reducing your operating costs saving tangible dollars.

The

Interoperable Automation Level providing open-protocol IP

convergence (source: ATC).

The Interoperable Automation Level is where the IP convergence happens,

and cross-protocol control logic is applied across all building

technology systems, making it a truly intelligent building. What is

critical at this level is one's knowledge and application of the open

protocols; the protocol's structure and rules need to be clearly

understood on both a hardware (topology) and software (engineering,

programming) level. This means for a system to become truly

interoperable, the links and data structure need to be clearly

understood, adhered to and defined on the IP level in order to provide

robust, cross-protocol logic.

To continue reading, click here

http://knxtoday.com/2020/04/15587/view-from-america-ot-interoperability-the-key-to-intelligent-buildings.html

About the Author

Philip R. Juneau is the Chief Commercial Officer for Automated Technology Company (ATC), and Vice President of the KNX USA National Group. ATC's mission is to transform today's buildings into tomorrow's net-zero infrastructure by ensuring the highest levels of safety, comfort and efficiency for the overall well-being of the occupants and the overall environment.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]