|

November 2011

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

|

Submetering for

Improved Building Operations & Maintenance Performance

Whether designed in or

retrofitted, submeters are installed

on the “building side” of the main utility meter to measure energy

usage from the enterprise level all the way down to a single device or

circuit.

|

Don Millstein,

President and CEO

E-Mon

|

Facility

operators need ways to operate more efficiently,

cost-effectively and with less downtime. When it comes to proactively

managing energy consumption and demand, electric submeters and energy

intelligence software are rapidly becoming the high-tech tools of

choice, especially where facility operations and maintenance are

concerned.

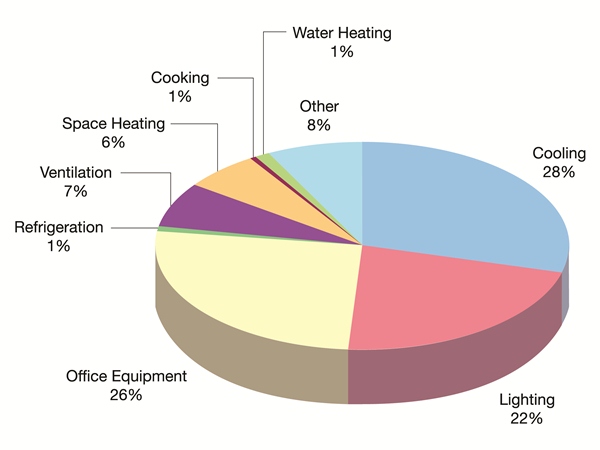

Quoting

Department of Energy stats, Flex

Your Power, California’s

statewide energy efficiency partnership of utilities, businesses,

government agencies and other entities, states that the commercial

building sector uses approximately 66 percent of all electrical energy

consumed in the United States. From 1989 to 2005, for example,

consumption of electricity doubled, a trend that, if sustained, will

likely see another 150 percent increase by 2030. Consuming roughly 23

million Megawatt-hours (MWh) of electricity, office buildings

themselves account for almost 30 percent of all commercial energy

demand. With energy representing some 30 percent of a building’s total

operating costs [1], electrical consumption by end-use category may be

extrapolated according to the break out shown in Figure 1.

Figure 1. Commercial building electrical

consumption by using source,

based on data from a DOE 1999 end-use consumption survey. Notice that

lighting and cooling alone account for 50% of all consumption, and the

significant impact of plug load on facility demand.

Needless

to say, the pervasive use of electronically powered technology

across the facility landscape has placed unprecedented demand on the

electrical grid. In many cases, however, the energy is wasted through

inefficient equipment operation, avoidable demand peaks and other

facility operational issues that are relatively easily and

inexpensively mitigated through proper operations and maintenance

procedures. In fact, it is estimated that a 30 percent reduction in

energy use can lower operating costs by up to $25,000 per year for

every 50,000 square feet of office space. Moreover, in terms of

commercial asset value, this translates to every dollar applied toward

increasing energy efficiency resulting in a three-to-one return

[1].

As

shown in Figure 1, lighting and the HVAC/R load represent 64 percent

of the facility’s energy consumption and a great opportunity for

energy-efficiency monitoring. Typical electrical and electronic devices

suitable for operations and maintenance programs include:

•

Boilers and steam traps;

• Chillers and cooling towers;

• Energy management and building automation systems;

• Air compressors and air handling systems;

• Fans, pumps and motors;

• Lighting systems.

Typical Maintenance Strategies

There

is much more to a proper and effective facility O&M strategy

than simply repairing equipment after it breaks. Several different

types of maintenance strategies may be employed concurrently by the

facility to optimize system operation, reduce downtime and minimize

disrepair. Since every facility is unique to its own operational needs,

the following strategies may be combined in some measure to maximize

system life-cycle effectiveness and cost-effective operation. Note that

the Dept of

Energy expresses relative costs in terms of dollars per horsepower per

year [2]:

[an error occurred while processing this directive]Reactive—“run

it until it breaks” offers the advantages of less staff

required and a low cost of on-going maintenance, but can result in

unplanned equipment downtime, increased cost for equipment repair or

replacement, possible downstream equipment/process damage and others.

At $18/horsepower/year, reactive is the most expensive strategy

according to DOE (FEMP) statistics.

Preventive—equipment

failure is avoided by regularly scheduled

maintenance which provides the advantages of greater

cost-effectiveness, flexibility, increased equipment lifespan and lower

failure rates. Disadvantages include the continued potential for

catastrophic failure, labor intensity, waste due to unneeded

maintenance and others. At 12-18% cost savings versus reactive,

preventive strategies typically cost around $13/horsepower/year.

Predictive—condition-based

strategy that examines the current status of

the equipment before determining what, if any, maintenance is required.

Advantages include a 10x return on investment, 25-30% lower maintenance

costs, 70-75% fewer breakdowns, 35-45% lower downtime and 20-25% higher

productivity, according to DOE figures. The downside includes higher

investment in diagnostic equipment and staff training, and harder to

quantify savings potential. At $9/horsepower/year, predictive results

in an 8-12% cost savings over preventive strategies and a 30-40%

savings over reactive.

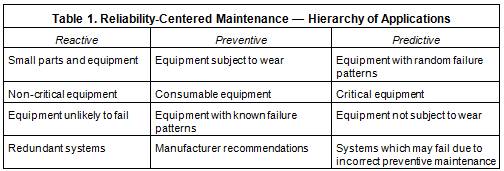

Reliability-centered

(Table 1)—employs many of the same practices as

predictive but takes into account that all equipment is not of equal

value nor does it offer the same probability of failure. Less important

equipment might be relegated to a reactive or preventive strategy. At a

typical cost of $6/horsepower/year, the advantages and disadvantages of

RCM are similar to predictive, but the former more closely matches

facility resources to needs while decreasing costs even further.

Table 1. Reliability-centered maintenance (RCM)

incorporates elements

of other strategies, based on relative importance or value of the

equipment in question. Meters are ideal, low-cost data acquisition

tools for characterizing these loads. Source: FEMP “O&M Best

Practices Guide,” P. 5.6.

Metering Approaches Useful in Facility

O&M Programs

Whichever

maintenance strategy combinations are employed by the

facility, the usefulness and value of metering is beyond question,

particularly in profiling the high-usage loads broken out in Figure 1.

When properly used, that information can lead to dramatic economic

savings of 20 percent or more by allowing facilities managers to:

•

Chart energy usage;

• Compare energy usage by day, week, month or year;

• Monitor all utility services, including

electricity, gas, water and steam;

• Schedule energy data collections to occur

automatically;

• Evaluate, in real-time, the impact of critical

load-shedding activities;

• Determine specific processes that are not

energy-efficient;

• Identify poor equipment performers by benchmarking

energy levels at multiple facilities.

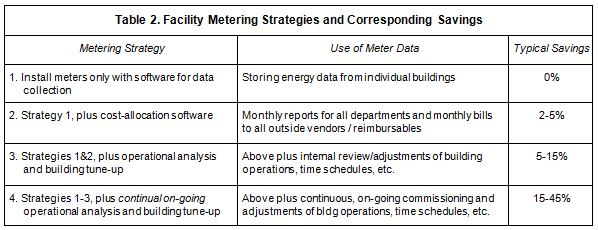

Table 2. A number of effective metering

strategies may be implemented

by the O&M program to achieve a sliding scale of savings based on

the hardware and software systems employed. Source: FEMP Fact Sheet,

January 2005 [3].

Once meters are installed and commissioned, they may be employed in a

variety of ways (Table 2), depending on the application, to control

costs, diagnose equipment problems, allocate usage costs, set resource

efficiency goals and any number of other uses.

Figure 2. Advanced submeters like E-Mon’s Green Class

series [4]

provide a scrolling LCD display of CO2 emissions, kWh and other

sophisticated energy measurements that can help users gain green

facility certification points under the LEED rating system.

Essentials of Submeter Operation

Submeter

manufacturers have responded to the “green challenge” by

developing next-generation hardware and software tools that

specifically address the measurement and verification (M&V) needs

of LEED v3 and other green building energy initiatives dominating the

sustainable facility market. Certified to ANSI C12.1 & C12.16

national accuracy standards, advanced submeters (Figure 2) typically

offer a number of important functions for new construction or retrofit

applications, including:

•

Scrolling LCD display of kilowatt-hour (kWh) usage;

• kWh in dollars;

• Current demand load (kW);

• Cost per hour, based on current load;

• Estimated CO2 emissions in pounds, based on DoE

standards;

• Estimated hourly CO2 emissions based on current

load;

• Net metering, including utility-delivered vs.

user-received power and net usage;

• Compatibility with BACnet, LonWorks, Modbus,

Ethernet, RF and other popular building automation system

communications;

• Integration with automatic meter reading (AMR)

systems for billing and analysis;

• View energy usage and carbon footprint data via

easy-to-understand dashboards accessible from standard web browsers;

• Compatibility with water, gas, steam, BTU and other

pulse-output utility meters. (Figure 3)

Figure 3. Whether designed in or

retrofitted, submeters are installed

on the “building side” of the main utility meter to measure energy

usage from the enterprise level all the way down to a single device or

circuit. Sold through distribution, today’s submeters are easily

interfaced with water, gas and other pulse-output utility meters to

provide a total facility energy snapshot.

Meter Dashboards Simplify Energy

Data Presentment

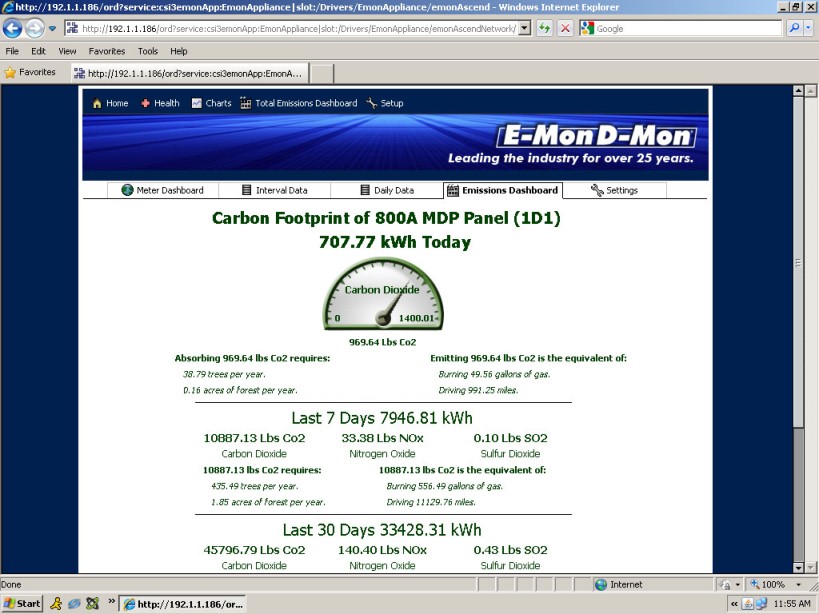

Internet-enabled

energy monitoring and data presentment dashboards [5]

are gaining traction in the facility environment for displaying kWh,

kW, peak demand, power factor and other energy measurements in real

time, and historically, while also displaying the facility’s “carbon

footprint.” This allows facility occupants to monitor their building’s

carbon dioxide (CO2), sulfur dioxide (SO2) and nitrous oxide (NOx)

emissions—while at the same time observing estimated energy

conservation measures needed to compensate for the displayed levels.

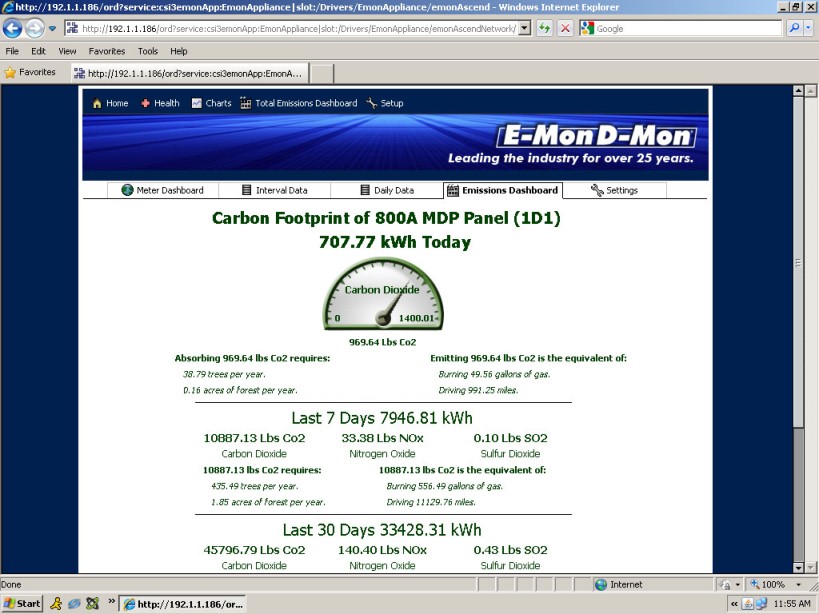

Figures 4-6 illustrate the sheer depth of energy information provided

by a single electric submeter.

Figure 4. Demand (kW) dashboard displays

the metered values of main

power panel “P” (blue) and an HVAC panel (red) in terms of coincidental

demand for both meters. The compare button at the bottom of the screen

displays another chart comparing the same set of meters for a different

time range.

Figure 5. Comparative demand (kW)

dashboard displays the metered values

of an HVAC panel (blue) and two lighting panels (red, green).

When selected, the compare button at the bottom of the screen displays

dual charts comparing the same set of meters at different time

ranges.

Figure 6. This carbon footprint dashboard

displays the real-time and

historical environmental impact of a specific meter based on

consumption (kWh). The main power panel “P” in this example is

characterized in terms of kWh today; number of trees and forest acres

required to absorb the CO2 in one year; and an extrapolation of

equivalent gallons of fuel consumed and miles driven. The CO2 dial at

top displays the equivalent emissions for the day, with the maximum

being the highest recorded level.

The Bottom Line is Always the

Bottom Line

The

type of sophisticated energy data needed to manage today’s

commercial and institutional facilities is beyond the capability of the

master utility meter to provide. As first-level data gathering tools in

the facility load-profiling process, submeters provide high-accuracy

15- or 30-minute snapshots of energy use (kWh) and demand (kW)—at the

enterprise level all the way down to a specific circuit or item of

equipment. Submeters are an easily installed, versatile and scalable

solution for obtaining the degree of energy intelligence granularity

needed to optimize today’s facility operations—no matter what type of

facility is being monitored.

From an

Operations and Maintenance perspective, meters help identify

operational inefficiencies, including revealing trends that may

indicate future problems. Demand spikes are also identified, allowing

facilities professionals to reschedule high-energy drawing loads to

off-peak times or stagger their duty cycles to lower the facility’s

demand profile. Considering the many uses of metering in the O&M

sphere, it doesn’t take too many “saved the day” scenarios for the

metering technology to more than pay for its own installation

costs.

About the Author

Don Millstein is President and CEO of Langhorne, PA-based E-Mon. As a

veteran energy industry speaker and author, Don is a former participant

in utility deregulation in California, New Jersey, New York and

Pennsylvania. He is a member of the FEMP task force, Alliance to Save

Energy, the U.S. Green Building Council and other energy

conservation-related organizations. He may be contacted at 800-334-3666

or dmillstein@emon.com

Sources and Links

[1] Flex Your Power “Best Practices Guide for Commercial Office

Buildings.”

Link: http://www.fypower.org/bpg/index.html?b=offices

[2] FEMP “O&M Best Practices: A Guide to Achieving Operational

Efficiency,” release 3.0 August 2010.

Link: http://www1.eere.energy.gov/femp/pdfs/omguide_complete.pdf

[3] Federal Energy Management Program Fact Sheet: “Facility Metering

for Improved Operations, Maintenance, and Efficiency,” January 2005.

Link: http://www1.eere.energy.gov/femp/pdfs/om_metering.pdf

[4] Green Class advanced submeter with CO2 carbon footprint data: http://www.emon.com/products_greenclass.html

[5] Web-Mon Internet-enabled energy monitoring dashboard: http://www.emon.com/products_webmon.html

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]