Figure

One: Smart Meter - Definition from Wikipedia

Figure

One: Smart Meter - Definition from Wikipedia|

October 2011 |

[an error occurred while processing this directive] |

|

Gain the Advantage of Open Standards

to increase Building Automation OEM Product Sales |

|

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

As

topics like Smart Meters and the Smart Grid become more and more

household names, a natural question that arises is how will data gained

from all of these” Smart Devices” be collected, distributed,

visualized, and turned from simply collected data into useful

information? A natural course of action would be for the OEM’s

and manufacturers of “Smart Devices” to create their own proprietary

software packages, drivers etc, to suit the needs of their customers,

but that breeds the same problem of interoperability and an ever

changing economy.

As everyone knows, the economy of the world has taken many twists and turns over the past five years and has had an impact on every industrial automation company in some shape or form. Building Automation projects were put on hold and are only now slowly coming back online. As projects come up, OEMs and machine builders face new challenges and vendors must rise to meet these challenges.

Customers are no longer satisfied with equipment that only communicates using proprietary technology, and can no longer afford to be locked into one vendor's product line. They need the flexibility to build quality solutions which will enable them to utilize the best equipment/software on the market. They need the ability to be able to easily integrate an HMI package that instantly communicates with common Building Automation protocols such as: BACnet, LONWorks, Modbus, proprietary and custom protocols, and to Johnson Control devices. They also want proven results that the equipment will increase production, decrease costs, and easy to integrate into existing systems. The challenge for OEM's is how to overcome these issues and sell more products with documented stats. That is where Open Automation Software took the ease of documentation of device performance as easy as the click of a mouse. One solution that Open Automation Software proposes is to use open standards to empower each device with the ability to connect to existing systems, and the ability to visualize and share real-time data though a Desktop, Laptop, iPad, or Smartphone such as an iPhone or Blackberry.

Figure

One: Smart Meter - Definition from Wikipedia

Figure

One: Smart Meter - Definition from Wikipedia

A smart meter is

usually an electrical meter that records consumption

of electric energy in intervals of an hour or less and communicates

that information at least daily back to the utility for monitoring and

billing purposes. Smart meters enable two-way communication between the

meter and the central system. Unlike home energy monitors, smart meters

can gather data for remote reporting. AMI differs from traditional

automatic meter reading (AMR) in that it enables two-way communications

with the meter.

This could be accomplished by using OPC Systems.NET. A service

orientated product, which is designed to take existing data and expand

it, so it can be accessed across the entire organization. This would

provide anyone accessing the system with the ability to visualize

real-time data directly from the source into whatever Visual Studio

capable graphics package that already exists on site, i.e. Auto Cad,

Blender 3D, Adobe Illustrator. The data from geographically

desperate Building Automation systems, including smart meters, could be

easily consolidated and displayed on a variety of devices with

a minimum of investment, but with a maximized return.

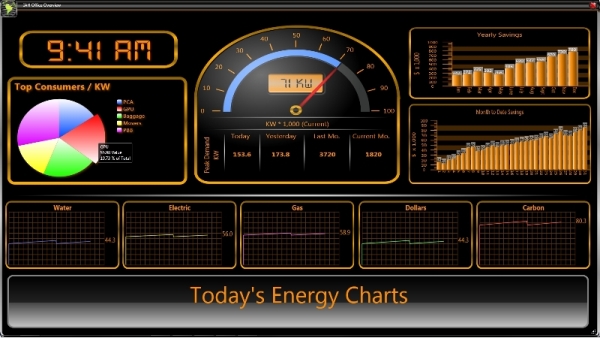

Figure Two: A visual example of the power and flexibility that the OPC Systems.NET software platform provides for end-users. It is flexible and easily customizable for any industry vertical.

OPC Systems.NET enables Building Automation OEM’s, and manufacturers, with the ability to get the real-time data needed to prove device capabilities, ease in client decisions and most importantly to illustrate how to maximize ROI. Data comes directly from the devices and is never touched by human hand, thereby eliminating any possible errors or manipulation. New components can be introduced into existing systems easily and the data from those components can be evaluated in real-time to gauge its impact. Direct data evidence can be taken to decision makers and provide a proven business case for purchasing more components to increase system productivity and efficiency. This eliminates the guess work when purchasing system components. The investment in Smart Meters or new Chillers can be justified and proven with factual data that can be measured. What can be measured can always be improved. Device manufacturer's who add OPC Systems.NET to their machines can increase their opportunity to obtain multiple orders from customers because evidence of their component's performance can be easily viewed by anyone in the customer's organization.

Figure Three: Customer Case

Study – Just one successful example

of how OPC System.NET was employed by JBT AeroTech to serve as the

backbone for their airport monitoring system.

“JBT AeroTech has used

OPC Systems.NET to create an airport monitoring system called iOPS™

(Intelligent Operations Performance System) Suite that links

maintenance management systems and aircraft avionics data to critical

ground-based monitoring, diagnostic and tracking systems on gate

equipment, baggage handling systems, facility systems and ground

support equipment. JBT is very excited about what we have done with OPC

Systems.NET”.

Stephen Tatton, Manager Business

Systems & New Technology

Read the full Case Study: http://www.opcsystems.com/casestudyjbtaerotech.htm

Data produced by OPC Systems.NET can be used to implement a predictive

maintenance schedule rather than a reactive one. Imagine how many times

a crew has been deployed to change bearings, fluids, and seals simply

because that is what the maintenance schedule dictates? By seeing the

data in real-time across the enterprise, maintenance schedules can be

predicted and asset lifetime can be extended.

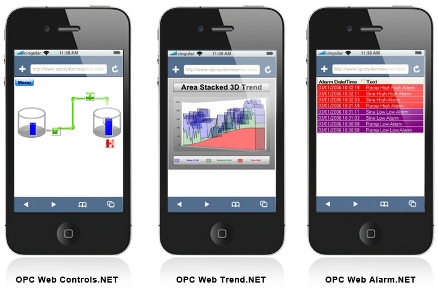

Figure Four – Thanks to the use of Open

Standards and the forward

thinking of Open Automation Engineering, OPC Systems.NET data can be

easily displayed on any web enabled mobile device to ease in the

scheduling of predictive maintenance.

[an error occurred while processing this directive] Parties interested in learning how to utilize Open Automation Software to gain the advantage in today’s Building Automation market can contact Jack McIntyre, EVP (Open Automation Software) to receive an interactive demo of just how easy it can be to integrate OPC Systems.NET and start harnessing the value of your data.

Download

a free trial of OPC Systems.NET and see the results for yourself.

Download @ http://www.opcsystems.com/downloads.htm

About Open Automation Software:

Open Automation Software was formed in 1993 with the vision of

empowering end-users and OEMs with the freedom to create the

applications they needed to truly build “best of breed” systems. Open

Automation Software achieved this by providing the tools to quickly and

easily develop SCADA products using Microsoft Visual Studio. The

culmination of this vision was the creation of OPC Systems.NET. OPC

Systems.NET is the flagship product for Open Automation Software and

leverages OPC standards from the OPC Foundation to enable secure

communications and support for Smart Clients, Web-based Clients and

Server, Mobile Clients, and Mobile Devices.

For

more information, refer to www.opcsystems.com.

[an error occurred while processing this directive] [Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]

[Click Banner To Learn More]