After application of continuous commissioning, technicians can focus on problems with the highest energy savings potential or probability of comfort violation.

Jan Široký

Research Team Leader

Energocentrum Plus

|

October 2016 |

[an error occurred while processing this directive] |

| Automated Continuous Commissioning After application of continuous commissioning, technicians can focus on problems with the highest energy savings potential or probability of comfort violation. |

Jan Široký Research Team Leader Energocentrum Plus |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

Introduction

Nowadays heating, ventilation and air conditioning (HVAC) systems do

produce enormous amount of data. These data are stored in building

management systems (BMS) ready for exploitation. However, in practice,

these data are not always utilized. The operator or local technician

usually does not have enough time to analyze all data. But what would

take hours to human operator can be done in seconds by a computer. The

problem is how computer can analyze data similarly to a skilled

technician. During the recent year, there was a shift from a simple

alarm notification to more advanced algorithms. One can find different

names for these emerging tools (e.g. energy intelligence software,

operational diagnostics, monitoring-based commissioning). In this

article we will use a term continuous commissioning. The main goal of

the article is to present results of application of continuous

commissioning in practice.

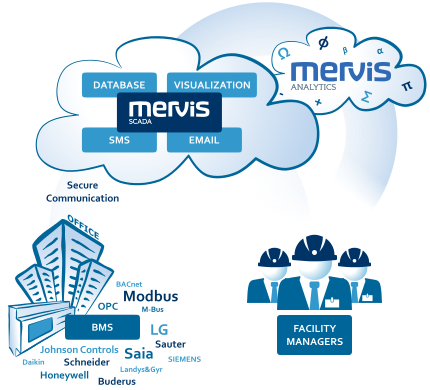

We will describe application of continuous commissioning to a customer

in the European Union. The customer has 150 mostly office buildings

connected to cloud based SCADA system Mervis ( https://mervis.info ).

More than 10 000 000 unique value records (e.g. temperature, valve

setpoint, energy consumption,...) are stored in database each day.

Apart from common SCADA functions (schemas, alarms, trends, messaging

…) Mervis offers analytical tools for everyday use. But all these bells

and whistles are almost useless once you have to work with tens of

thousands variables and any regular evaluation and analysis of the

historical data becomes a nightmare. That is a moment when the advanced

analytical methods of continuous commissioning proves the most valuable.

Before application of continuous commissioning, technicians were

dealing with the most urgent HVAC problems. Usually without

consideration of severity of possible impact. After application of

continuous commissioning, technicians can focus on problems with the

highest energy savings potential or probability of comfort violation.

Thanks to application of continuous commissioning significant energy

savings were achieved.

Technical solution will be described in the next chapter, followed by

the brief description of the used methods. Selected examples and

results summary are presented in the last section.

Technical solution

At the core of the continuous commissioning process

described in this article is Mervis - cloud service for complex

supervision of building and other technologies. Its foremost function

is to integrate different control and building management systems that

have been installed in above mentioned more than 150 buildings over the

last 20 years.

Technologies by Siemens, Johnson Controls, Daikin, Landys&Gyr,

Schneider, Buderus, Honeywell, LG, Saia, Sauter and many others were

integrated. The measured data are securely communicated over the

internet.

The basic rule is that all communicated variables (tags, data points)

are logged into the highly optimized database every three minutes but

the system allows for any sampling period starting from less than one

second. Even the least important variable can play significant role in

later data analysis.

Simplified topology of cloud based Mervis services.

Once the data are collected and available online - the facility managers can do their regular work of monitoring the building technologies. More importantly they receive a complex report derived from the historical data every week. The report highlights the most important violations of comfort, energy efficient regimes etc. but allows for deeper analysis of the data directly in Mervis cloud system using direct links to particular measured values stored in the cloud. Methods that are used for data analysis are briefly introduced in the next section.

Methods used

We are focused on methods that can be simply applied without time

consuming configuration and tuning. Except of data tagging, no special

data preparation is needed. All preprocessing, analysis and avoidable

cost calculation is done automatically, without any user input. Thanks

to this fact reports can be generated regularly on daily, weekly or

monthly basis. The goal is to process raw HVAC data and prepare summary

information for an expert that can validate the results and perform an

action if needed.

The following analysis can be performed:

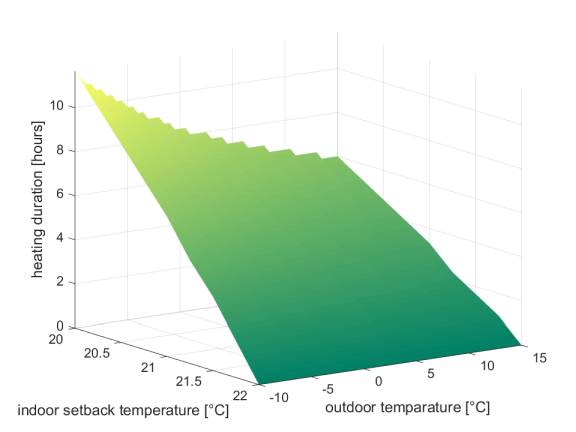

Each analysis uses different algorithms, from simple

rules (air

handling units) and basic statistical characteristics to sophisticated

methods such as neural networks (detection of non-standard profiles)

and mathematical modeling (heating system setback). Example of setback

analysis is depicted in the figure below.

Crucial part of the system is estimation of avoidable cost. If

possible, impact on energy consumption is estimated. The goal is to be

able to compare detected incidents in terms of avoidable cost, not to

provide a rigorous calculation of avoidable cost for each particular

incident.

Example of a heating

system setback

analysis. The chart depicts an

output of dynamical model simulation. The model is based on a real

building data. The green-yellow surface indicates time needed for

heating a building to 22 °C for different outdoor temperatures and

setback temperatures. For example, it will take more than 11 hours to

heat up the building from 20 to 22 °C when outside temperature is -10

°C.

Case study - results

As mentioned above, the described approach was applied to a building

portfolio of a customer in the European Union. The portfolio consists

of office buildings with a predefined regime (opening hours) and

similar usage patterns. Detailed knowledge of building regime (imported

from computer aided facility management systems) was crucial for the

analysis.

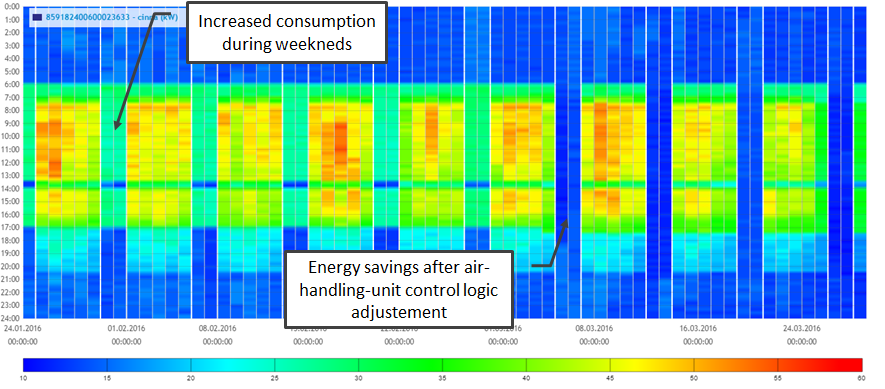

Electrical energy consumption outside office hours was identified as

the lowest hanging fruit. Complex evaluation of electrical energy

consumption with respect to building regime was performed. Ten

buildings with the highest saving potential were selected for a

detailed on-site investigation. The most common problem was wrong setup

of air handling unit time program. This was fixed by a simple

reconfiguration of building management system (no investment needed).

Outcome of such reconfiguration is depicted in the figure bellow. The

second common problem was lighting. In some cases lighting was turned

on outside office hours without any reason. In one case, we found an

oversized UPS. The UPS not removed after major reduction of IT in the

building. The overall savings achieved on ten selected buildings are $

20,000 per year with total investment lower than $ 4,000.

Carpet chart of

electrical energy usage. Weekly regime can be

recognized with significant reduction of weekend electrical energy

consumption after air-handling-unit regime adjustment.

This summer we had focused on unnecessary mechanical cooling outside

office hours. Again, we had selected ten worst performing buildings.

On-site investigation confirmed that the reason of suspicious

electrical energy consumption is cooling outside office hours.

Integration of autonomous cooling units into a monitoring and control

system was needed. Required payback three years was not satisfied in

most cases due to installation costs.

Application of continuous commissioning provided significant benefits

to a customer. We had performed evaluation of energy consumption of the

buildings before and after application of continuous commissioning. In

total, there was 9 % reduction of energy use after application of

continuous commissioning. Major advantage of continuous commissioning

is in long-term cooperation. It ensures that energy savings actions are

not ruined due to an inappropriate action (e.g. switch to manual regime

by a local technician). From this perspective, the customer is saving

several hundred thousand dollars each year.

About the Author

Jan Široký is leader of research team of Energocentrum

Plus company. Jan has gained his Ph.D. at the University of West

Bohemia, Department of Cybernetics. During his studies he

undertook an internship at ETH Zurich. The main activity of

Energocentrum is operation and servicing of energy equipment,

technological equipment of buildings and measurement and regulation. Energocentrum has its own research and development

department. This team develops software products for measurement and

control (e.g. cloud based SCADA system Mervis - https://mervis.info ).

Research team is focused on advanced control and monitoring algorithms

for buildings.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]