|

August 2015 |

[an error occurred while processing this directive] |

|

Don't Forget About Water

Data centers consume roughly as

much water in a year as 158,000 Olympic sized swimming pools.

|

Kristen Bauer

Brand Strategist & Robert O'Donnell, Managing Partner |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

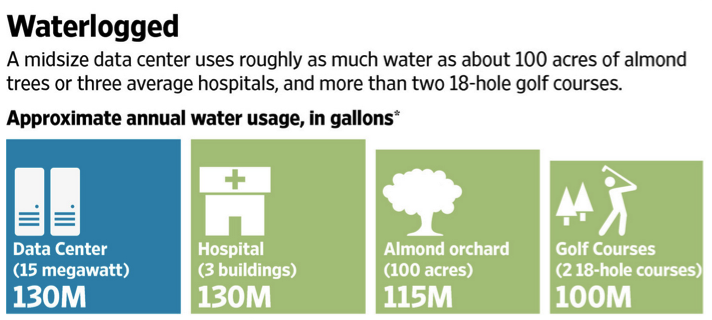

The

Wall Street Journal reported in June 2015 that, “California has more

than 800 data centers, the most of any state. Based on that and

estimates for water use, the state’s data centers consume roughly as

much water in a year as 158,000 Olympic sized swimming pools.”

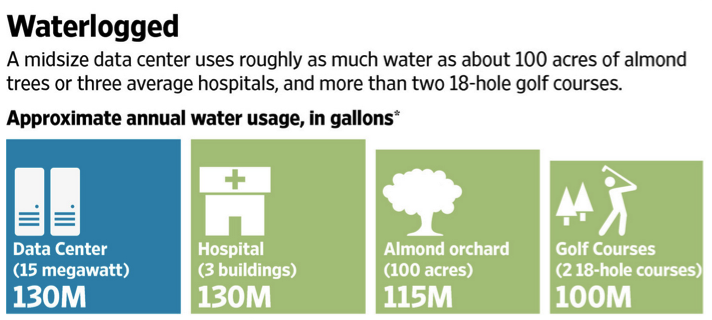

“A midsize 15-megawatt center uses between 80 million and 130 million

gallons of water a year for cooling, according to industry estimates.

At the high end of that range, each new facility is akin to planting

100 acres of almond trees, adding three hospitals or opening more than

two 18-hole golf courses.”

California Governor Jerry Brown has ordered cities across the state to cut annual water use by 25% - immediately.

______________

1http://www.wsj.com/articles/SB10007111583511843695404581067903126039290

The report stated what we in the

industrial water and controls industry already know, that, “Data

centers aren’t the state’s biggest water users. But they generally

require municipally provided clean, treated water like restaurants and

hotels. Agriculture, which accounts for roughly 80% of water use in the

state, can use untreated water from streams and lakes. Electric

utilities, the state’s second largest water consumer, also can

sometimes use salt water.”

Addressing how water treatment directly impacts heat exchange, energy

use, and water use will ultimately lead to a better water management

program, lower operating costs, and a significant improvement in

sustainable facilities management. Capital assets (hvac equipment) will

be preserved, postponing a capital event, leading to a stronger P&L

for the facility owner. While these new programs may be more demanding,

this type of service has significantly better profit margins, as

compared against open bid arrangements with no performance metrics to

define program success.

Historically, controls technology platforms allowed for treating these

operating systems by looking primarily at water quality data, and

maintained the water conditions using that singular data set. For

example, if the system ORP was low, then a subsequent increase in the

oxidant feed was delivered. However if the pollen count was high due to

seasonal conditions, we waited until we had a visual confirmation (by

visual inspection or by test) of resultant biological development and

then subsequently increased the biocide dosage.

We treated the water to keep a heat exchanger clean, but the water

treatment controller never received verification that the heat

exchanger was clean. There was no feedback from the building automation

system to the treatment system.

When it comes to commercial and industrial HVAC systems, cooling towers

tend to receive less attention than other HVAC system components.

According to Chris Walton of Baltimore Aircoil Co., “The cooling tower

is often the forgotten component of the system when it comes to

maintenance.”2

Yet, cooling tower maintenance is critical to ensuring overall system

efficiency, abating critical asset failure, and preventing downtime.3

Todd Beard, regional operations director, Lee Co., Franklin, Tennessee,

noted, “When a process or piece of cooling equipment depends on a

heat-rejection device such as a cooling tower to function properly,

there are not many alternatives that will work in the event the tower

fails. In other words, there is typically not a cooling tower sitting

in a warehouse somewhere ready to be installed at a moment’s notice.

It’s not a matter of if a poorly or non-maintained tower is going to

fail — it’s when.”

And, Beard added, “That is when Murphy’s Law comes into play, and the

failure occurs at the most inopportune moment; it happens every time.”

Water quality in industrial and commercial HVAC systems requires smart

instrumentation for analysis, allowing you to proactively address

problems arising from changing make up water chemistries. It also

requires smarter control methods to predict and respond to upcoming

conditions that could cause corrosion, scaling, fouling, or microbial

upsets. This newer control technology must be connected to the systems

being treated so that the controller is not blindly treating water for

a heat exchange system it cannot see. Instead the control software

architecture that monitors the water quality characteristics should

also look at the hvac system heat exchange performance data, and

preferably, the atmospheric conditions as well.

Marrying the water quality data with the hvac system performance data

allows the advanced controls system the opportunity to aggregate and

analyze data by running algorithms to determine underperforming system

components.

______________

2http://www.achrnews.com/articles/129575-dont-ignore-that-cooling-tower

3http://www.achrnews.com/articles/105135-cooling-tower-safety-and-maintenance

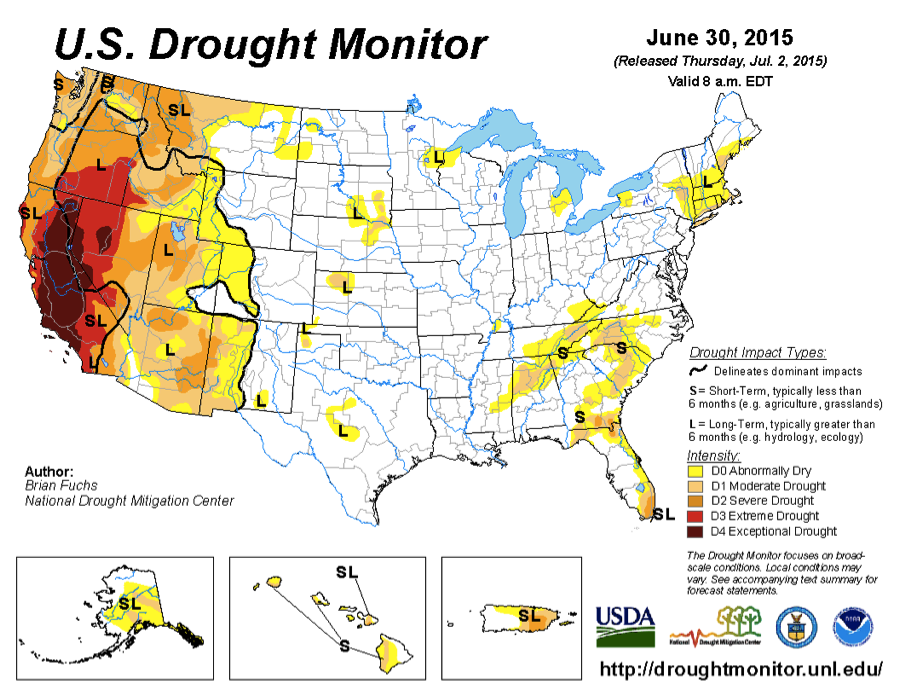

SYSTEM BENCHMARKING

You’ve heard the same adage over and over again. You cannot manage what

you do not measure. It’s all about the data, but without a benchmark or

a way to structure data, it renders this potentially valuable resource

as little to no value to a facility manager or enterprise level

executive. It must be organized in a cohesive way to explain the data

relationships – in this case, the relationship between heat exchange

(energy efficiency) and water quality.

We don’t know what we don’t know.

Facilities managers, enterprise managers, building owners, the

powers-that-be expect, and usually require, a veritable return on their

investment in data – information that empowers them to make the right

decisions. Data and knowledge provide power – understanding how and why

heat exchangers are functioning at any given moment is powerful.

Combining that previously disparate knowledge of the cooling system

operations is priceless.

Data is power.

That is the magic of an effective benchmarking tool – giving the owner,

the manager, whoever – the visibility, full transparency of what they

are spending on water and energy – and who is responsible for any

inefficiencies and OpEx expenditure.

It’s also effective from an enterprise level – benchmarking each system

against one another to garner the relational data between all

facilities/buildings in an enterprise portfolio.

The value in a technology that marries energy and water quality data is

powerful. It reveals transparency of operating costs and water quality

management at such a granular level. The data supports swift and

intelligent decision-making processes, which can save money and improve

outcomes in performance.

Symphony™ helps data centers, other critical facilities, any commercial

or industrial building improve reliability and efficiency. By

continuously monitoring and analyzing the water quality and energy use,

you minimize risk, both critical and operational. As a result, you can

get the reliability that management demands.

[an error occurred while processing this directive]

Here’s how it works:

The numbers don’t lie.

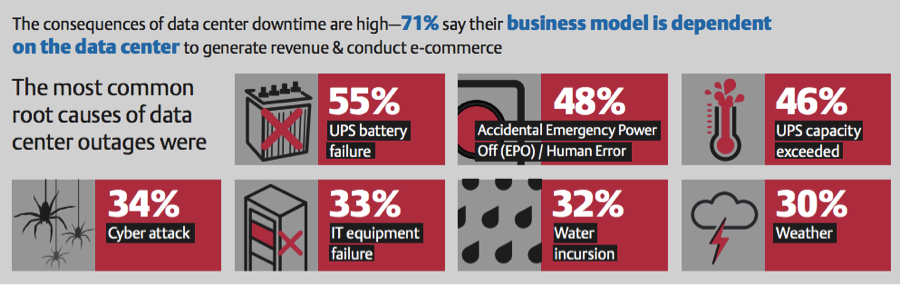

84% of data center managers would rather walk barefoot over hot coals

than endure data center downtime, but 91% experienced an unplanned

outage in the past 24 months.

32% of all unplanned outages in commercial and industrial buildings

result from water-related issues at an estimated $500,000+ per outage.4

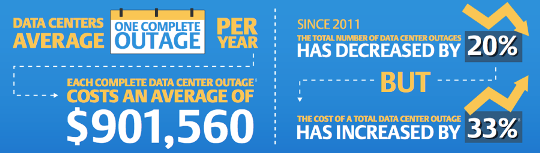

Data centers average one complete outage per year – each complete data center outage costs an average of $901,560.5

______________

4 Emerson Network Power: http://www.emersonnetworkpower.com/en-US/Solutions/infographics/Pages/Causes_of_Downtime.aspxand

http://www.emersonnetworkpower.com/documentation/en-us/brands/liebert/infographics/documents/ponemon-infographic-cost%20of%20downtime-r11-13-

final.pdf

5http://www.emersonnetworkpower.com/en-US/Solutions/infographics/Pages/State-of-the-Data-

Center-2013-Infographic.aspx

It’s tough to manage what you can’t, or

don’t, measure. If the main goal of a maintenance or facility

professional is to maintain an efficient and operational HVAC system,

while maintaining today’s critical sustainability component, smart

water and energy efficiency technologies must be implemented into

commercial and industrial buildings.

About the Author

Kristen A. Bauer, Brand Strategist

Kristen Bauer is the Brand Strategist

at Aquanomix, LLC, based in Davidson, North Carolina, and has more than

ten years of experience in the marketing and advertising industry.

Kristen specializes in marketing, communications and advertising in the

diverse industries of professional sports and engineering.

Prior to launching the revolutionary new Symphony water management and

optimization software for Aquanomix, she worked seven years for NASCAR,

Inc., as well as working in the advertising agency world managing and

strategically promoting Fortune 100 clients.

Kristen is a member of the American Marketing Association.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]