February 2010

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

February 2010 |

[an error occurred while processing this directive] |

|

This article is meant as more a paean to the Automatic Temperature Controls industry than a eulogy. |

Thomas Hallett |

The

pipe trades birthed it, and now the IT industry has buried it. What once was

pipe and fit is now plug and play. The proud American factories which cast brass

and stamped steel for manufactured products are empty and shuttered;

sweat shop labor in Bangalore and Mexico City now furnish solutions. What

the creative industrial genius of Mark C. Honeywell, Professor Warren Johnson,

and William Penn Powers raised from the cradle sits now in an urn, a collection

of ashes displayed only in museums, confined to history.

The

pipe trades birthed it, and now the IT industry has buried it. What once was

pipe and fit is now plug and play. The proud American factories which cast brass

and stamped steel for manufactured products are empty and shuttered;

sweat shop labor in Bangalore and Mexico City now furnish solutions. What

the creative industrial genius of Mark C. Honeywell, Professor Warren Johnson,

and William Penn Powers raised from the cradle sits now in an urn, a collection

of ashes displayed only in museums, confined to history.

This article is meant as more a paean to the Automatic Temperature Controls industry than a eulogy; as the ATC business was a tender nursemaid to my career, I write now as her docent.

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

THEY WERE GIANTS

Messrs. Honeywell, Johnson, and Powers were to a man, American industrial and

business giants; renaissance men all, each was classically schooled and imbued

with native curiosity and blessed with a magnificently conductive wire from head

to hands. None of these men were what today we would call a graduate engineer.

Rather, they grew to maturity in the time following the civil war when central

heat was in its infancy, commercial electric power was confined to only a few

blocks surrounding a power station, and business success required only

inspiration, perspiration, perseverance, and pluck.

Just as a

farrier must know his animals, these men first knew combustion, boilers, heating

distribution, and piping. They cut their teeth on the mechanical systems being

developed, installed, and serviced in homes and buildings as our growing nation

gave up fireplaces and coal-fired parlor stoves and welcomed the cleaner and

more evenly distributed central heat furnished by H. B. Smith, Peerless,

Kewanee, and others.

Just as a

farrier must know his animals, these men first knew combustion, boilers, heating

distribution, and piping. They cut their teeth on the mechanical systems being

developed, installed, and serviced in homes and buildings as our growing nation

gave up fireplaces and coal-fired parlor stoves and welcomed the cleaner and

more evenly distributed central heat furnished by H. B. Smith, Peerless,

Kewanee, and others.

Be it vapor, low pressure steam, or even hot water, these

mechanic-inventor-engineers saw an application for controls that hitherto had

mostly been manual. They were equally at home in the laboratory/workshop or the

boiler room; to have called any of them a specialist would have been an insult

to their intelligence and creativity. "Leaking boiler section?, sure, no

problem". They'd take a hammer and pin punch and seal the leak.

"Stuck trap?, sure, no problem". Would they tell you "sorry, not my

job....you'll need to call a specialist". Not on your life! Yet, when observing

an obvious shortcoming with the mechanical delivery of central heat, each man

produced a product that took it a step beyond and hastened the acceptance and

eager embrace of what we now so take for granted..........the little round

thing on the wall that makes us comfy.

BUILD IT, INSTALL IT, and SERVICE IT

The soon

to be captains of ingenuity and enterprise found willing investors eager to

build, market, and install the high-tech products born of Johnson's,

Honeywell's, and Powers' genius. William Plankinton, heir to the Plankinton

Packing Company backed Warren Johnson to form the Milwaukee Electric

Manufacturing Company; Plankinton was president and Johnson was vice-president

and treasurer. On May 1, 1885, the company was reorganized as the Johnson

Electric Service Company, a Wisconsin corporation, in Milwaukee.

The soon

to be captains of ingenuity and enterprise found willing investors eager to

build, market, and install the high-tech products born of Johnson's,

Honeywell's, and Powers' genius. William Plankinton, heir to the Plankinton

Packing Company backed Warren Johnson to form the Milwaukee Electric

Manufacturing Company; Plankinton was president and Johnson was vice-president

and treasurer. On May 1, 1885, the company was reorganized as the Johnson

Electric Service Company, a Wisconsin corporation, in Milwaukee.

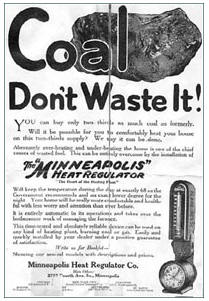

In

1906 Mark C. Honeywell started the Honeywell Heating Specialty Co. in Wabash, IN

to manufacture hot water Heating Systems for homes. This was the first use of

the name Honeywell as a company. In 1927 Minneapolis Heat Regulator Co. merged

with Honeywell Heating Specialists and becomes Minneapolis-Honeywell Heat

Regulator Co.

In

1906 Mark C. Honeywell started the Honeywell Heating Specialty Co. in Wabash, IN

to manufacture hot water Heating Systems for homes. This was the first use of

the name Honeywell as a company. In 1927 Minneapolis Heat Regulator Co. merged

with Honeywell Heating Specialists and becomes Minneapolis-Honeywell Heat

Regulator Co.

Thus the American plumbing and heating industry birthed the automatic

temperature control business. Messrs. Johnson, Honeywell, and Powers along with

their investors created the bricks and mortar manufactories to cast brass,

machine parts, and assemble thermostats, valves, relays, gear-train actuators,

thermowells, and a host of field devices which, once installed, became a

system. Branch offices were established, A/E firms given guidance with spec

writing, and engineers trained with the application and start-up of these

new automatic control devices.

[an error occurred while processing this directive]

Professor Johnson had insisted that only trained Johnson mechanics could install

his company's devices and his successor, Ellis reinforced this policy. He

insisted that the company was to serve not just as a producer of regulation

equipment but as a single source for design, installation, and service. In

short, Johnson expected his employees to be fully versed with not only his

products, but their proper application, installation, and operation. Soon, ASHVE

(the predecessor to ASHRAE) embraced and developed sequence standards for the

operation of the temperature control system.

Application engineers relied upon their product knowledge training and mentoring

from senior pioneers to interpret a spec, select the products, layout and design

the panel, field devices, size valves and dampers, and gain A/E (and owner)

acceptance. This was still the practice when I joined the business in 1978. I

fondly recall the drawer full of cardboard product templates used to layout a

panel........put the receiver-controller here, the ratio relay there, and slide

in the e/p switches on the side. Yes, it all fits with room to spare for easy

servicing.

AN

ENGINEER IS SOMEONE WHO CAN DO FOR 50 CENTS WHAT ANY BLOODY FOOL CAN DO FOR A

DOLLAR.......Nevil Shute

AN

ENGINEER IS SOMEONE WHO CAN DO FOR 50 CENTS WHAT ANY BLOODY FOOL CAN DO FOR A

DOLLAR.......Nevil Shute

Engineers also bore the responsibility to design an installed system which

turned a profit for the firm. Along with a shop drawing, a project budget was

produced. This budget was formulated from the materials cost, panel assembly

labor, install labor, start-up, and warranty expectations.

Yesterday's application engineer was truly a well-rounded systems man, well

versed in controls product knowledge, mechanical systems operation, and held a

fiduciary responsibility to turn a profit for his employer. From drawing board

to gleeful customer acceptance, he was the steward of both his employer's and

customer's expectations. He used a steam calorimeter with the the same ease as

his pencil on vellum.

I know this as I was mentored by such a man. "Coolie" Richardson had been with

the Barber-Colman Company for over 40 years when I was hired to replace him.

Rich with experience, he still kept up youthful exuberance and welcomed me to

his drawing board. No Luddite he, I was amazed to see he used a program written

in BASIC to size valves.........yet he still kept his drawer of cardboard

templates for panel layout. To this day, I hope still to fill his shoes.

THEY ARE MIDGETS

The

inheritors of the fine, old staid firms of the Johnson Service Company, the

Minneapolis-Honeywell Heat Regulator Company, and the Powers Regulator Company

preside now over firms that are controls manufacturers in name only. Car seats,

aviation/avionics, or medical instruments/scanners are the true bread and butter

for these once proud designers, manufacturers, and installers of automatic

temperature control products and systems.

The

inheritors of the fine, old staid firms of the Johnson Service Company, the

Minneapolis-Honeywell Heat Regulator Company, and the Powers Regulator Company

preside now over firms that are controls manufacturers in name only. Car seats,

aviation/avionics, or medical instruments/scanners are the true bread and butter

for these once proud designers, manufacturers, and installers of automatic

temperature control products and systems.

Sure, they've slick websites touting in "corporatese" how they furnish

solutions, but try calling a branch office to buy a thermostat.......if

you get a return call, it will likely be the day after tomorrow! From the

top on down, these firms are populated with sycophants and wannabe's. Take no

risk, show no initiative, ingratiate yourself with the corporate leadership, and

you'll land a cushy spot at headquarters.

Don't dare insist on top talent, just take what's been blessed from the HR

oracles. Don't dare bid a job without first the corporate lawyers' exhaustive

vetting of your proposal. Don't dare challenge the vanguard of marketing

strategy for setting up jobbers to compete with the branch.

In short, behave just like a D.C. bureaucrat.........after all, your firm is

nothing short of the federal government in microcosm.

Now let's look at what sort of technical talent these corporate chevalier

servants have cultivated:

"Commissioning

Technicians" they are now called. Once there were "techs".......guys who would

troubleshoot a vacuum tube driven mod motor in the morning, replace a pump-down

solenoid after lunch, and write machine language code for a Motorola 6800 in the

afternoon.

"Commissioning

Technicians" they are now called. Once there were "techs".......guys who would

troubleshoot a vacuum tube driven mod motor in the morning, replace a pump-down

solenoid after lunch, and write machine language code for a Motorola 6800 in the

afternoon.

Skilled with both a TTL/CMOS logic probe and a sling psychrometer, these techs

were not only skilled professionals, but possessed that intuitive wire from head

to hands with which the giants were blessed..

Knowing how to read a logic diagram, read and utilize a psychometric chart, and

measure superheat across a coil were all in a days work. Well before today's

crop of mouse clicking "programmers", techs of old could calculate the volume of

a timing tank on a P+I receiver controller to tune their loop. Yes, proportional

plus integral controls existed long before DDC systems came on the scene.

Oftentimes, yesterday's tech found himself on a remote campus or military

installation with an entire building down......no communicado! The building's

loop remote or data gathering panel was not reporting to the central station.

The branch office was 300 miles away, and the needed spare circuit board was not

at hand. What was readily at hand were the schematics, logic probe, and the

skill to fully use both. "Ah-ha", said the tech, "your transmission line

interface board has a blown opto-coupler", no problem to run to the nearby

Radio-Shack and pick up a 4N26 and replace the dead chip. THAT is customer

service of which Professor Johnson would be proud.

CONCLUSION

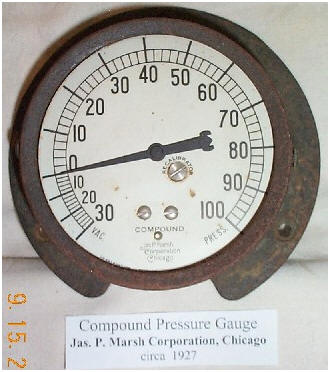

That

today's "commissioning technician" cannot understand a 3-way light switch

circuit in your dining room is a direct result of the feckless leadership and

lack of vision afflicting management in today's control business. Ask a tech

today what a bourdon tube is and he'll give you the same deer-in-the-headlights

look you'd get from the branch manager when posed with the same question.

That

today's "commissioning technician" cannot understand a 3-way light switch

circuit in your dining room is a direct result of the feckless leadership and

lack of vision afflicting management in today's control business. Ask a tech

today what a bourdon tube is and he'll give you the same deer-in-the-headlights

look you'd get from the branch manager when posed with the same question.

For the owner whose AHU failed to start leaving a classroom at 50° for the

students, don't expect your tech will get up from the computer, take his wiggy,

and go to the fan room. No, "the system sent the command, I don't know why the

AHU failed to start". The owner must now call another specialist just to tell

him the fan starter has a bad overload.

Why the acceptance of mediocrity?

It comes from the top. When the individuals running these firms are more

interested in this quarter's income statement than the investment of bricks,

mortar, and talent that it takes to be the best in the business, all you'll get

is a click of the mouse and a shrug.

When slick Power-Point presentations, buzzwords, and "corporatese" replace

American Know-How, all you may expect are "solutions".

When solid technical talent, deep product knowledge, and experienced leadership

such as what Professor Johnson insisted upon come a calling, you may expect

RESULTS.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]