January 2005

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

January 2005 |

[an error occurred while processing this directive] |

|

Automation Takes a Bite Out of the $400+ Billion Commercial Food Service Industry |

Michael Burdett |

Jim Skinner (Vice Chairman and CEO of McDonald’s™ Corporation) stated to The Economist magazine in an October interview “If you are looking for a command centre with one push button that operates our restaurants in every corner of the world, you won’t find it.” Well Jim, we found your button and it’s on a mouse…and that command center, it’s anywhere there is a computer connected to the Internet.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

Many of you will be attending the ASHRAE Expo next month. And this year, as in year’s past, you will find literally thousands of new or improved items. But this year, take a moment to ponder vertical applications for these items. Ask yourself, are you taking advantage of new developments in technology or are you just marketing new technology to the same old markets? With any successful business you need to constantly adapt to stay on top. Consider what new opportunities would be created by a product’s introduction to your product line. Markets that were previously not cost-effective have become viable by technological advancements in design and decreased manufacturing costs. A keen example of this is Arecont’s approach to dominate the multi-billion dollar franchise restaurant industry.

Four years ago Arecont Systems, Inc., manufacturer of

the Kontar™ Control System (AHR Booth #1065), set out to design an automation

control system that would revolutionize large commercial and industrial building

automation by creating a more-powerful, lower-cost, truly Internet-based (not

just web-enabled) controller. After successfully achieving this design goal they

realized that their central server approach (i.e. Arecont Global Hub™) made the

system a superior solution for light-commercial, franchise and restaurant

applications that were previously cost-prohibitive. Upon recognizing this, they

refocused their marketing efforts and now lead the $400+ billion commercial food

service industry in automation control equipment and services.

Four years ago Arecont Systems, Inc., manufacturer of

the Kontar™ Control System (AHR Booth #1065), set out to design an automation

control system that would revolutionize large commercial and industrial building

automation by creating a more-powerful, lower-cost, truly Internet-based (not

just web-enabled) controller. After successfully achieving this design goal they

realized that their central server approach (i.e. Arecont Global Hub™) made the

system a superior solution for light-commercial, franchise and restaurant

applications that were previously cost-prohibitive. Upon recognizing this, they

refocused their marketing efforts and now lead the $400+ billion commercial food

service industry in automation control equipment and services.

Their SCADA (Supervisory Control and Data Acquisition) interface now accommodates unique hospitality features such as temperature logging, drive-through timers, soda fountain monitoring, DVR camera integration, sign and lighting control, power monitoring, climate systems control, and still maintains an open design structure that makes it configurable for virtually any control task you can dream up. It wasn’t a radical departure from their commercial/industrial applications, but this paradigm shift opened new doors of opportunity to their dealer channel. “It was a logical market for many HVAC equipment contractors, engineers and architects. Most have existing clients that would benefit from automation control systems, but the current market offering were too costly and limited for restaurant applications. Now a multiple franchise owner can sit at his home or office computer and oversee all his operations on a system that typically has less than a 2-year R.O.I.” said Arecont President, Daniel Reich, PhD., CEM.

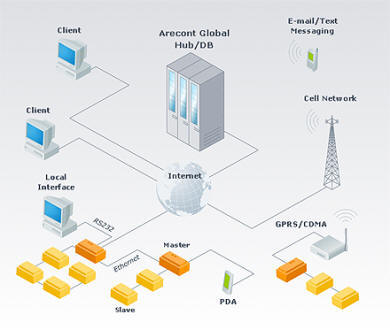

The revolutionary, patented, global hub architecture allows for an economical, yet more powerful solution. The system cost was significantly reduced by utilizing an offsite server for complex tasks like GUI (Graphical User Interface) hosting, task logging, reporting and alarming. And since it doesn’t require an onsite server, system reliability is increased and minimal IT knowledge is required of the installer. The monthly subscription cost is less than most security monitoring fees and a portion of that fee is returned to the installer as recurring revenue.

Communication is handled through an RS-485 network of controller modules. Each controller has 22 I/O ports (8 analog inputs, 4 digital inputs, 8 digital outputs, and 2 analog outputs) and can be configured as a master or a slave unit. Up to 31 slaves may be used in a conventional network configuration, however with the addition of their ZigBee™ wireless modules and sensors (demonstrated at the Arecont booth at ASHRAE) a virtually unlimited number of I/O devices may be networked. This should prove more than adequate seeing that a standard quick-service install, such as McDonald’s, typically requires fewer than 6 controllers. The master controller interfaces directly with the Internet through an inexpensive Weblinker™ card and can interface with a local RS-232 device such as a PC or PDA.

[an error occurred while processing this directive] So why is the restaurant market such a big deal? Why focus on a small restaurant application when the same controllers are suited for high-end, big dollar, commercial applications? Quite simply, this is an excellent untapped market. Franchise restaurants are frequently cookie-cutter designs that are simple installations and can be replicated throughout the entire network of stores. Your first installation may be a bit more complex, however many of these franchisees hold literally hundreds of stores. The benefits become clear after the first installation and additional locations can be secured rather easily.

Another reason is the number of critical HVAC, refrigeration and temperature logging tasks required of each franchise location. Most franchise corporations require their franchisees to report (or at a minimum maintain logs) on refrigeration temperatures, meat temperatures, drive-through statistics, and other tasks for liability and quality control reasons. Most of these statistics are manually entered and have questionable accuracy. Automation allows for precise, automatic logging, and can improve diagnostic evaluation at a corporate level. Additionally, early detection of equipment and refrigeration problems alarming to mobile phones, pagers or email can save the store owners literally thousands in spoiled inventory costs, emergency maintenance expenses, and lost revenues from equipment downtime. Even the camera integration can be easily justified as employee theft and slip-and-fall liability claims top restaurateur’s list of concerns (according to the National Restaurant Association). Best of all, the energy efficiencies gained from the automation system in the notoriously inefficient restaurant industry can result in a 2-year return-on-investment.

Recent trends in the fast food industry have led the largest franchise corporations to refocus their growth by improving the profitability of existing locations rather than growth through new construction. This includes boosting franchise ROI by trimming expenses and remodeling existing stores. As automation experts we need to seize this opportunity to help them while we help ourselves.

For more information on Arecont™ or the Arecont Kontar™ System, please visit www.arecont.com or email your contact information to info@arecont.com for a free presentation CD and a live, online demonstration. Michael Burdett is the VP of Sales and Marketing for Arecont Systems, Inc., a U.S. company with over 300 employees worldwide.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]