July 2007

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

July 2007 |

[an error occurred while processing this directive] |

|

|

Joy Null CASE STUDY |

SANTA CLARA, CA June 2007 – Vermont-based manufacturer NRG Systems in 2005 built a new headquarters carefully crafted to reflect the company’s commitment to the environment, the community and its employees. The 46,550 square foot facility, which includes office, manufacturing and warehouse space for company-produced wind monitoring equipment, was designed to minimize environmental impacts and maximize energy conservation.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

Project goals

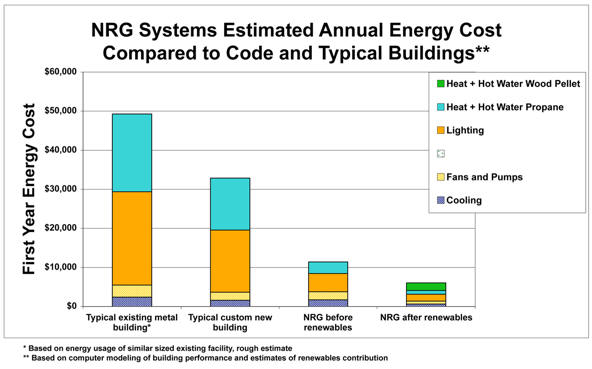

The first design goal was to find ways to minimize energy needs in

all areas of building operation, including heating, cooling and lighting. The

second goal was to provide as much energy from renewable sources as possible.

Company owners were willing to make an upfront investment to ensure significant

long-term savings.

Naomi Miller of Naomi Miller Lighting Design specified the electric lighting and Andy Shapiro of Energy Balance, Inc. developed the facility’s daylighting plan. The two designers collaborated with Watt Stopper/Legrand to select energy saving controls that would meet the ambitious criteria of the project.

Daylighting contribution and

controls

Careful building orientation and design allows daylighting to provide

significant contributions not only in office areas, but warehouse spaces as

well. Light-guiding blinds, coupled with strategically placed windows and

skylights, bring daylight deep onto the building and provide an abundance of

diffuse, low-glare lighting.

Augmenting the daylight is an electric lighting system consisting primarily of high-performance, T8 fluorescent lamps with dimming ballasts controlled by Watt Stopper daylighting controls. Photosensors constantly monitor outdoor lighting levels and controllers automatically adjust the fluorescent lighting to maintain the desired ambient levels. A multi-zone control strategy is used in the office areas so that fixtures closest to the windows dim first as daylight contribution increases.

Carefully directed daylight and

dimmable fluorescent lighting combine to provide optimal lighting levels

whenever the space is occupied. Sensors prevent any energy waste.

Occupancy sensors

Additional energy savings are achieved by using occupancy sensors

throughout the building and grounds to ensure that lights are not on unless the

space is in use. Most are set with the manual-ON option selected in order to

maximize energy savings.

Passive infrared, ultrasonic and dual technology sensors have been installed according to the size and function of each space. Dual technology sensors, advantageous for applications not ideally suited to either PIR or ultrasonic technology alone, are used in several offices and a large board room. This approach ensures the greatest sensitivity and coverage with the least threat of false triggers. Both technologies must detect occupancy before the sensor turns the lighting on, but continued sensing by just one technology will hold the lighting on.

Special weatherproof sensors are used for outdoor areas and are rated for temperatures from -40° to 130° Fahrenheit. Vermont can deliver some brisk temperatures!

The spaces using natural lighting employ sensors along with the daylighting controls to maximize energy savings while at the same time helping NRG Systems keep its commitment to being a good neighbor. Community residents also benefit from the sensors as they reduce light pollution from the skylights after dark.

Lamp and ballast selection

NRG Systems’ electric lighting primarily uses high-performance T8

lamps combined with programmed start electronic ballasts for maximum light

output and long life. Low, normal, and high-output ballasts were specified for

different spaces to customize the light output appropriately and squeeze every

possible Watt out of the lighting operation.

While this approach sounds simple, it complicated the design and construction processes. Multiple fixture tags were required for each basic fixture type, baffling suppliers who didn’t understand the ballast differences, and submittal reviews became complicated. Additionally, the contractor had to be careful about putting identical-looking fixtures in specific rooms. Downlights, wall sconces, and decorative pendants primarily use 32W compact fluorescent lamps. Limiting the number of lamp types on the project simplifies maintenance and allows owner to economize by purchasing replacement lamps in volume.

[an error occurred while processing this directive]

System tuning

When asked whether the lighting and controls systems performed

perfectly right away, the designers responded, “No. There were a few

compatibility issues that had to be resolved and required getting the luminaire

manufacturer, ballast manufacturer, lamp manufacturer and the controls

manufacturer involved in a conversation with us and the owner’s electronics

guru.” After taking field measurements, observing the behavior of the system and

waiting for laboratory test results, Shapiro and Miller discovered that certain

fixtures specified with a single three-lamp ballast had been shipped with a

single-lamp and a two-lamp ballast and the added current draw of having two

ballasts per fixture was overloading the system. Additionally, the lamps

provided were not compatible with the ballasts, so the fixtures had to be

reballasted to resolve these problems.

The designers also discovered a misunderstanding about the standard operation of the daylighting controller, which they intended to have switch lights off on bright sunny days. Once the desired operation was communicated to engineers at Watt Stopper/Legrand, they were able to provide instructions on how to re-wire the controller to produce the desired results.

Shapiro and Miller recalled that the electricians experienced some difficulty implementing systems where luminaires were controlled based on input from both daylight and multiple occupancy sensors due to the complexity of the resulting sensor/relay/ballast/switch wiring diagrams. They noted, “Commissioning the sensors took a significant amount of time, particularly given the owners’ desire to minimize electricity usage, which required repeated adjustment of sensitivity and off-delay time settings. However, the time in commissioning paid off. The systems are now working as expected.”

Design achievements

All of this careful attention to detail resulted in a lighting design

that was estimated to use about one third of the energy of a typical new custom

building. The connected lighting load for the building is a scant 0.77W/sf –

over 46% less than ASHRAE/IESNA 90.1-2001 allowances. Continual energy

monitoring has proven the benefit of the control strategy and actual daytime

lighting energy use is over 40% less than the connected load, even in winter

months. Actual electricity usage by lighting was very close to expectations,

consuming 40,000 kWh from March 2005 through February 2006. The building is one

of only a handful of manufacturing facilities to earn a LEED Gold certification.

NRG Systems also succeeded in its goal of using low cost energy and is supplying

72% of the energy used from renewable sources, which include solar, wind and

wood pellets.

Company founders David and Jan Blittersdorf report having paid an 8.21% premium on the $7,833,000 project for the specialized design and construction, including a substantial investment in a photovoltaic system. According to David, “We have essentially prepaid our energy bill by relying on renewable energy and, a result, we won’t have to worry about rising energy costs in the future.” He estimates a $4-8 million saving over the 30-40 year projected life span of the building. Of the approximately $643,000 in premium building costs, $460,000 was for renewables and $183,000 ($3.93/sq. ft.) was the LEED cost premium. Designer Andy Shapiro concludes, “the cost premium for the daylighting design, coupled with carefully selected energy-efficient luminaires and controls is rapidly repaid in miniscule utility bills.”

NRG Systems limited energy use

in all aspects of its building operations. The lighting uses about 1/3 the

energy as that of a typical new custom building.

Watt Stopper/Legrand is a leading manufacturer of energy efficient lighting controls for commercial and residential use. We help customers find convenient ways to save energy, meet green initiatives, and comply with energy codes with our comprehensive range of products, programs, and services. Legrand, located in Limoges, France, is the world specialist in products and systems for electrical installations and information networks. Visit www.wattstopper.com.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]