Talk of integration as something new is the mark of someone way behind the times.

James Palmer

Sales and Business Development

North Building Technologies Ltd

|

June 2016 |

[an error occurred while processing this directive] |

| Integration is

not the future Talk of integration as something new is the mark of someone way behind the times. |

James Palmer Sales and Business Development North Building Technologies Ltd |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

In

fact, integrating at machine to machine level is expected and an

everyday part of almost every project we now work on. Yet not all BMS

manufacturers see it that way.

We have all seen the rise of the Japanese air conditioning system. They

are ubiquitous, and interfacing to them is a standard part of almost

all major projects. Air Handling units, chillers and boilers all now

tend to come with packaged controls. Yet few building management

systems on the market have integration at their core.

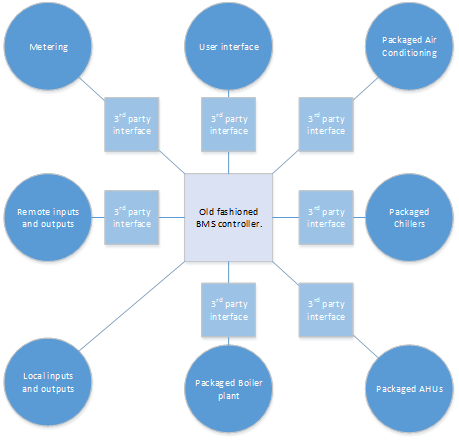

The old fashioned BMS relies on physical inputs and outputs to connect

to the real world. For most, integrated communications are an

afterthought, often provided by a third party gateway; almost as if

this sort of thing is non-standard.

Reluctance to engage by many of the main players causes needless

complexity and expense on projects. Yet large parts of the market

accept this. Should they? I think we first need to understand why this

is the case.

Pointless Control

I’ve

been in the industry 23 years now, and for as long as I can remember

the cost of a BMS project could be quite easily guesstimated by the

number of “points” (sensors, relays, contactors, valves etc.) that

require monitoring and control. Add up all the inputs and outputs,

times them by about x and you have something approaching your project

value.

This model relies on all points being physical inputs and outputs. When

half the points you are controlling are attained by a few data

connections (as they often are now) the model starts to fall apart. One

data connection could gather a thousand values from a system, yet no

one would dare charge the standard multiplier for a single interface,

no matter how many "points" are collected.

Self-preservation society

The

result of all of these packaged controls entering the market has been a

slow whittling away of the physical point count on projects, which is

reflected in decreased BMS contract values. In a somewhat short-sighted

move, rather than adapting technology and looking for a new model, the

major manufacturers chose protectionism. And for a while it worked. By

ignoring integration, the whole discipline was given an air of

complexity and specialism it didn’t quite deserve. The negatives of

integration were expounded while the positives were swept under the

carpet, dissuading many re-sellers from ever attempting true

integration. Simply by making integration appear more complicated it

became more expensive and therefore less attractive.

However, as open standards proliferated, manufacturers had to respond.

The demand in the market was huge. Many simply paid lip-service with

proprietary versions of open standards which ticked enough boxes to

meet a spec but left a lot to be desired in terms of true openness.

Proprietary protocols are still the norm on many systems (Mitsubishi,

Daikin, Panasonic air conditioning for example), and the wide range of

standards (KNX,

LON, BACnet, Modbus, Dali, MBus)

means controllers need to support more than one protocol at a time to

be truly open. And even though the market demands it, very few

controllers available today could be classed as truly "open".

Disruptive Technologies

This situation left a gap for smaller companies to produce gateway products that sat in between the old fashioned BMS controllers and modern packaged systems.

The

old fashioned method is to buy a controller and put it in a panel, then

pull hundreds of cables back to that panel. You then buy another box

from a third party and use it to establish comms with your packaged

plant, then spend hours transferring values into your BMS controller

and then repeat for all other systems.

Independent firms grew large libraries of drivers and developed

hardware technologies to deploy them. As the market demanded more and

more integration, so the main players dug their heels in harder and

harder. The levee finally broke when the smaller integration companies

stepped up and started putting the ability to control as well as

integrate into their devices.

Here at North we developed our Object Verse cause and effect language

for our Commander controller and introduced our own range

of physical, distributed IO modules (Zip).

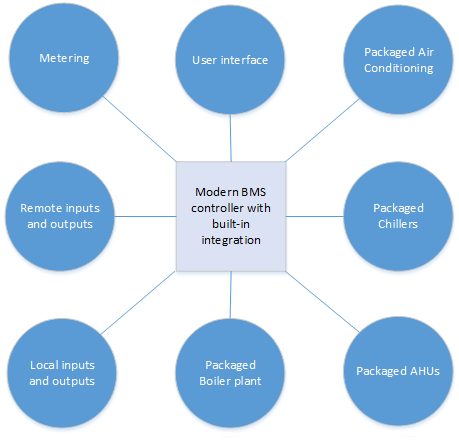

This gave the market what it had been asking for all along, a single

controller that could communicate with many disparate systems, while

monitoring and controlling what physical IO was left on the job.

Meet the new boss, better than the

old boss

The main players have been slow to respond. Smaller manufacturers may have taken a while to get

the message out, limited marketing budget can do that, but the message

is now out there and we are winning market share.

North’s

system allows engineers to create control strategies that treat package

controls and I/O in the same way. We provide a low cost distributed I/O

modules, which can reduce installation costs and our controller (Commander)

plugs directly into package AHUs, package chillers, meters and Air

conditioning systems. The engineer sees no difference between a value

from the AHU or from our I/O modules. All values are available to all

parts of the system all of the time.

The argument for a modern integrated control system is easy to make.

The market has now decided that this is what it wants. It’s an exciting

time at North, we are integrating systems now and have been for many

years. The future? Well, that is in development as I type...

To become a North partner contact me here, or email sales@northbt.com

About the Author

James

Palmer joined North straight out of University and has now been with

the firm for 23 years. Starting in technical support, James is now in

charge of sales and business development at the Brighton (UK) based

company.

North Building

Technologies Ltd make

control products for buildings. Our controllers link systems together

to optimise building performance, and our user interfaces simplify

building management. Our products are configured for domestic,

commercial and industrial buildings by trusted resellers, installers

and OEMs.

North are an independent company based in Brighton, UK since 1995.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]