|

March 2012 |

[an error occurred while processing this directive] |

|

Wireless Commissioning and Market Mega Trends Wireless commissioning can be easy, and large market forces are pushing its adoption to supply the growing demand. |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

People like me spend a

lot of time discussing the current and future

market impact of wireless technology in building automation. Today, I’d

like to be more specific and demystify what wireless means at the field

level. Although it may seem obvious to some, wireless commissioning is

still a mystery to many.

First, I’ll take you through the tedious, painful process of

commissioning wireless devices and networks. Then, I will address the

mega trends that are pushing more and more building stakeholders to

prescribe wireless in their building automation solutions.

Warning: I take for granted that you’ve heard about the EnOcean and

ZigBee wireless protocols. If you haven’t, look them up.

Commissioning of wireless sensors

and actuators

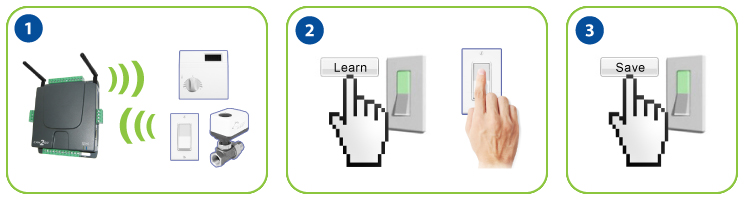

I will

be blunt and concise. Here’s how you can establish wireless

communication between an EnOcean device and a CAN2GO controller (BACnet

IP compatible):

How you can

commission EnOcean devices with CAN2GO controllers

That’s

it. This is one way to commission wireless devices in a building

automation project.

Network commissioning

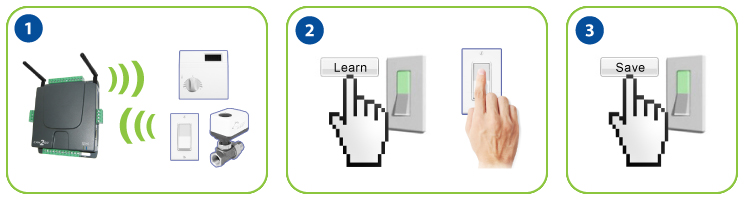

I will

unfortunately have to be blunt and concise again. Here’s how you

setup a ZigBee wireless mesh network for a group of CAN2GO controllers.

How you can create a

ZigBee network with CAN2GO controllers

That’s

it. Wireless discovery and meshing is automatic. This is one way

to create a wireless mesh network of controllers in a building

automation project.

As you can see, I lied. These processes are neither tedious nor

painful. This is wireless building automation today. Consider the issue

demystified.

Things to keep in mind

When

deploying wireless devices and networks, system integrators should

always keep in mind that wireless protocols have different wavelengths,

range and bandwidth. The range can be affected by building materials

and obstacles such as elevator shafts.

[an error occurred while processing this directive]As with wired deployments, it is important

to plan ahead. One little

known advantage of wireless building automation is that you can link

controllers and peripherals in the comfort of your office before

deploying them in the field. This is a best practice that we

recommended. The only task remaining on site is to position the devices

within wireless range of each other. Of course, because communication

is wireless, it’s easy to relocate devices or add repeaters to ensure

reliable communication within the environment.

Mega trends pushing wireless in

building automation

Now

let’s shift gears and go back to our marketing comfort zone to look

at the mega trends steering the present and future of the building

automation industry.

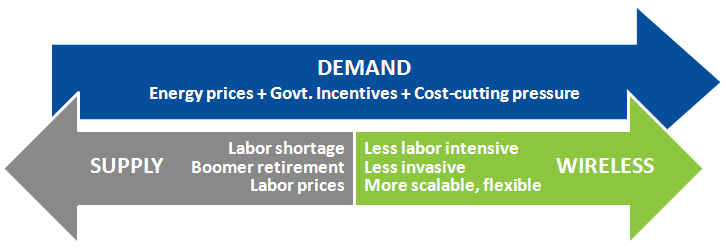

There are three mega trends fuelling a large increase in demand on the

retrofit side. (1) Energy prices tend to increase, not decrease. (2)

Since the economic crisis, governments have invested in subsidies,

incentives and regulation to push energy efficiency measures in

buildings. (3) The crisis has also put more pressure on companies and

institutions to cut costs, and energy efficiency is a great way to

achieve this goal with payback periods ranging from 1 to 5 years with

building automation.

Now here’s the kicker: there are also three mega trends limiting the

market’s response to this increase in demand. (1) Despite the crisis,

there is a current labor shortage in our industry, as explained in this

article: “According to several recent surveys, most

small business

owners around the country do not plan to hire due to the uncertain

economic outlook... Parts of the HVAC industry seem to be trending in

the opposite direction, however, as many contractors say they are

planning to hire over the next 12 months — if they can find the

qualified people... Unfortunately, there are too few qualified

individuals for these open positions.” (2) This labor shortage will get

even worse as baby boomers start going into retirement. (3) Labor

prices, the main variable cost in building automation projects, will

remain high.

So, the unstoppable force of increasing

demand for energy efficiency in

building is about to run into the immovable object of qualified labor

shortages. The one way to circumvent this problem is to deploy systems

that rely more and more on wireless technologies, because they can be

deployed quickly. This allows contractors to do more projects in the

same amount of time. It also holds many direct and indirect advantages

for the building owners and facility managers.

Market & demographic

mega trends are favoring wireless in building automation

Client side benefits

The

direct advantage of using wireless in building automation is to

lower the total cost of ownership of systems; which translates into

faster payback periods. This can vary depending on the project type,

but wireless does reduce labor, repair, wiring and conduit installation

costs.

The indirect advantage of using wireless control and networking

products is a reduction of collateral costs. Traditionally, installing

a building automation system has always been an invasive process that

created inconvenience for building owners, managers and occupants.

Closing a store, a wing, a floor, a department, a classroom or an

office just for system installation means losing productivity; losing

money. Wireless allows for speedier and more discreet installations,

reducing the indirect costs of productivity loss. Less wires, more

value.

The permanent advantage of wireless systems is low-cost scalability and

flexibility. Adding more points to a wireless enabled system is easy.

It can be done at any point during the lifetime of the system for

minimal cost. No need to add gateways, inputs/outputs extenders and

pull wire. Just add the new points in range of your existing system.

The same is true for point relocation. If a sensor is deemed to be in

the wrong place, wireless devices can be relocated with minimal labor.

This is why building owners, facility managers and engineering firms

are increasingly specifying wireless components for their projects.

Overall, the combination of supply/demand mega trends and client side

benefits is steering building automation the wireless way.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]