|

March 2012

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

Deploying a

High-Performance Wireless Monitoring and Control Network

A

reliable wireless system

should be able to transmit data through various types of building

materials, tolerate interference from other devices, and recover from

disruption to the network.

|

|

Much has been

written about the benefits of wireless technology for

building automation, HVAC control, and energy management. Over

the past several years, wireless technology has improved greatly in

terms of performance and lower power consumption. Product

innovations have also accelerated as regulatory certification has

become less burdensome with the FCC’s approval of

pre-certified wireless modules.

The most obvious benefits of wireless solutions are rapid deployment

and low installation costs, especially for retrofit applications where

wiring is prohibitively expensive. Facilities constructed with

lots of concrete block (e.g. K-12 schools), with asbestos, or projects

where running conduit is required, are all great candidates for using

wireless technology to reduce costs. Wireless is also a great

solution where installation is time sensitive or where occupant

disruption has to be kept to a minimum.

Wireless Applications

Wireless

can be used for a wide range of applications from simple

point-to-point links to a facility-wide network, for real-time control

or just monitoring and data logging. Example wireless sensors

include temperature, humidity, light level, differential pressure and

pulse meters. And new, low-power wireless CO2 sensors are now

enabling rapid wireless retrofits for demand-controlled ventilation

(DCV). DCV can deliver substantial energy savings with a

relatively short payback timeframe, as documented in a study by the US.

Department of Energy. A wireless solution makes DCV

implementation faster and easier than wiring.

Temporary data logging is an often-overlooked wireless application,

such as during an energy service company (ESCO) pre-investment

audit. In this case, wireless data logging with the ability to

push sensor data to the cloud in real-time, is far more useful and cost

effective than repeated trips to collect data loggers, download their

data, and redeploy them. Instead, ESCOs can use a wireless system

for pre-investment audits, and then leave it in place for monitoring

during the life of the performance contract.

Wireless Technology and Robust

Performance

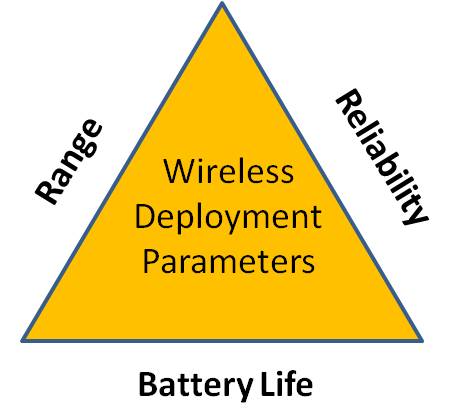

The

three most important considerations when designing and deploying

wireless-based professional HVAC and energy-management systems are:

battery life, range, and reliability (see Figure 1).

Figure

1: Key wireless deployment parameters

Battery

Life

Wireless devices with short battery life result in higher maintenance

costs and potentially reduced system efficiency, with subsequent lost

energy savings, when such devices fall out of the network because their

batteries aren’t replaced. Many wireless sensors on the market

today are specified with 3-5 years of battery life, though some systems

may reach 7 years if they’re configured for longer sampling

periods. Over time, the repeated cost of battery replacement

negates the benefits of wireless technology, and even limits the scale

to which facility managers are willing to deploy a wireless system.

One solution to the problems surrounding batteries is to harvest energy

from other sources, such as solar or artificial light, to create a

perpetual power source. The challenge is that indoor solar harvesting

is not reliable in all scenarios because it is an intermittent energy

source, and not available in places that receive no light. HVAC

system designers and facility operators need sensors to provide

reliable data all the time, not just intermittently when a device

receives harvested power. Adding a battery improves performance,

but rechargeable batteries do not have the same operating life as

high-quality primary batteries.

Consider a battery-based system that could operate for 25 years or

more, sending data every minute. This kind of system would provide more

reliable performance than one based on indoor light harvesting, and

would eliminate the issue of battery replacement, because the control

system is likely to be replaced before the battery is depleted.

Range

Range can impact both system cost and battery life. Lower

frequencies, higher transmission power, repeaters, and none-to-node

meshing are various techniques used to extend range. Some

component manufacturers and system providers promote various flavors of

mesh protocols as a way to extend range, by having data hop from one

sensor node to another until it reaches the destination gateway.

There are benefits to this approach, but they come at the expense of

latency and battery life. For example, the data from a sensor

node that is five hops from a gateway will take 5 minutes to get there

if each node wakes up and listens for data once per minute.

Listening for data from another node is an expensive use of finite

battery energy. Applications requiring real-time, or near

real-time performance may not be able to tolerate this type of

delay. For HVAC control, such a delay means greater swings in

environmental conditions which impacts occupant comfort, and reduced

system efficiency leading to higher energy consumption.

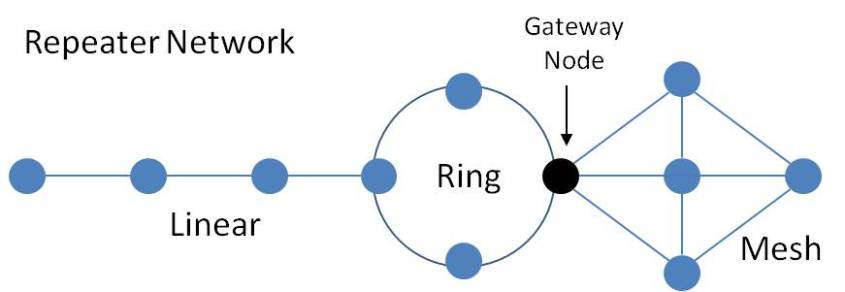

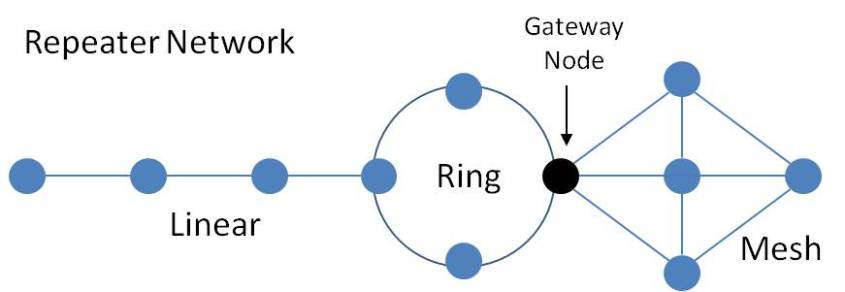

Line-powered repeaters can forward data in real-time, which is a better

approach to extending range in commercial building control

applications. Repeaters are easily installed in utility closets

and require minimal configuration. Repeaters should be capable of

extending range to unlimited distance and form a network of various

topologies including linear, ring, and mesh (see Figure 2). A

repeater network maximizes the network’s range while preserving battery

life of the sensor devices. Repeaters that use smart forwarding

techniques will not forward duplicate packets from multiple sources and

thereby reduce the overall amount of network traffic, which also

improves wireless performance.

Figure

2: A repeater network links various topologies (linear, ring and mesh)

to extend range.

Reliability

Reliability, or the ability of wireless transmissions to reach their

intended destination, is critical. A reliable wireless system

should be able to transmit data through various types of building

materials, tolerate interference from other devices, and recover from

disruption to the network. Lower frequencies propagate through

building materials better than higher frequencies, and users can employ

various modulation and frequency agility mechanisms to minimize or

overcome the effects of interference. Some systems simply

increase the transmission power to force the signal through, but this

solution potentially interferes with other signals, and also reduces

battery life.

[an error occurred while processing this directive]

An alternative to achieve reliable signal performance is to combine

both robust modulation and frequency agility. From a wireless

network perspective, using a line-powered repeater network in a mesh or

ring configuration enables multiple paths back to the gateway. A

properly-designed repeater network is inherently self-healing in the

event of a disruption. Additionally, implementing multiple

wireless gateways such that redundant gateways can receive the same

information enhances overall system performance. These gateways

can be in different areas, fed by different power circuits, and

connected to different network routers. In the event of a

failure, the control system can switch over to the backup gateway.

Example Wireless Sensor System for

HVAC, Building & Industrial Automation

Powercast

has developed a wireless sensor system intended to provide

good range, link and system-level reliability, and the longest battery

life available in the building controls industry. The company’s

goal was to provide the convenience and flexibility of wireless with

the predictability and longevity of wired solutions. The

Powercast Lifetime Power Wireless Sensor System offers:

•

25+ year battery life – using proven battery technology and

transmitting at one-minute internals

• Long range –

including unlimited network range, and real-time network performance

• High reliability –

supports frequency agility, self-forming/healing network, and redundancy

Wireless Sensors

Most wireless sensors for our system are available in small,

4”x2”x1” enclosures and are suitable for wall-mounting in commercial

office buildings (see Figure 3). They can be configured off-site

and deployed rapidly on-site. Sensor types include:

•

Temperature

• Humidity

• Light level

• External

temperature probes

• External dry

contacts

• Carbon dioxide

(CO2) – self calibrating

• Differential

pressure

Figure

3: Sensors come in small, 4”x2”x1” enclosures suitable for

wall-mounting.

We

designed our wireless sensors for very low power consumption,

which results in their ultra-long battery life. We have also

performed several simulated, worst-case, accelerated battery life tests

which confirmed operation for longer than 25 years. The company has

produced a test report (free download) to document the test

procedure

and results.

Wireless

Gateway

Supports up to 100 devices and connects to any BAS or IT system

using standard protocols including BACnet, Modbus, LonWorks, Metasys

N2, SNMP, XML, and more. Also supports data logging to a local PC

or connectivity to the cloud for remote monitoring.

Wireless

Repeaters

Support linear, mesh, ring, or hybrid topologies with real-time

latency performance. The repeater network is inherently

self-forming, self-healing, and capable of unlimited hops.

More information is available at www.PowercastSensors.com

About the Author

Harry Ostaffe is vice president of marketing and sales at Powercast

Corporation, and has over 23 years experience in the fields of

broadband and wireless networking, industrial controls, and computing

through various management and engineering positions at Ericsson,

Marconi, Lucent Technologies, AT&T Network Systems, Bayer and

IBM. Harry received an MBA from Carnegie Mellon University and a

B.S. in Electrical Engineering from Penn State University.

www.LinkedIn.com/in/HarryOstaffe

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]