|

March 2013 |

[an error occurred while processing this directive] |

| New Management Platform Combines Advanced Technology and Professional Staff to Optimize Building Performance |

Dan Probst, Chairman, Energy & Sustainability Services, Jones Lang LaSalle |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

Achieving optimal performance from a building or portfolio requires two essential elements: advanced technology that can monitor systems and equipment, and organize the data into useful formats; and professional building staff that can use the data to make effective decisions on maintenance and repairs. However, investing in the latest automation systems and maintaining a large professional staff can get expensive. Portfolio owners must balance the upfront and ongoing costs against achievable savings and the potential for enhanced revenue as a result of higher performance. For large portfolio owners, the combined cost of automation and experienced staff may seem to exceed the benefits.

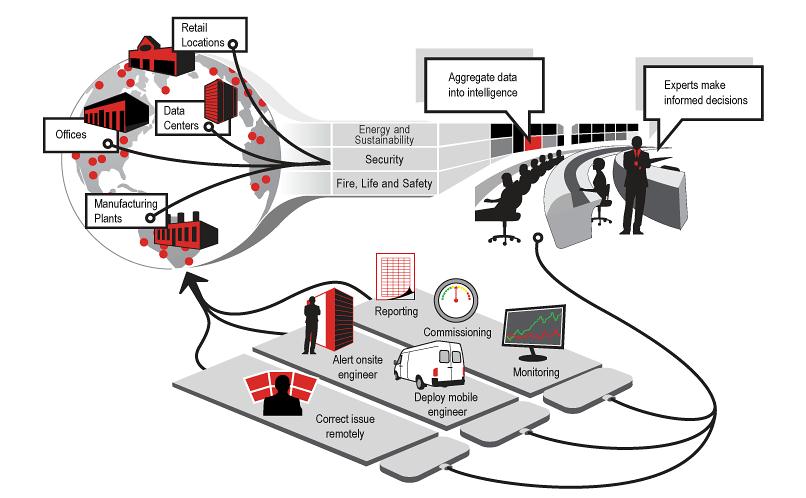

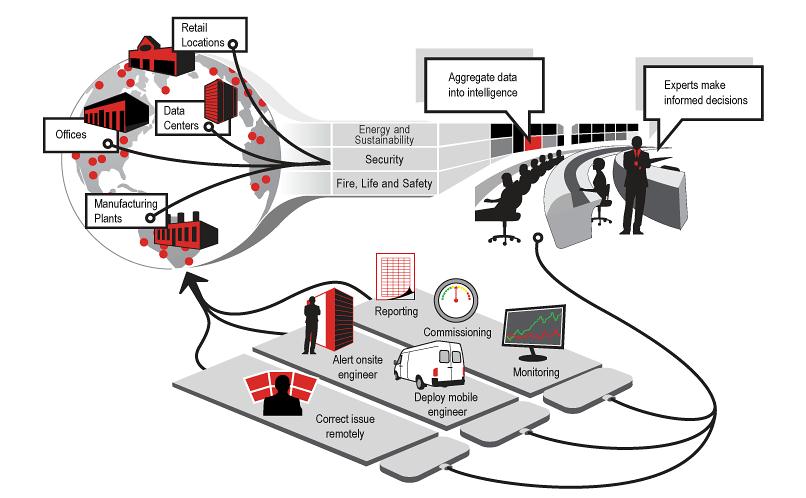

Seeking to overcome this challenge, global real estate services firm Jones Lang LaSalle and automation solutions provider Pacific Controls Inc. teamed up to develop an integrated facilities management platform. The new platform is IntelliCommand(SM), the commercial real estate industry's first monitoring and control solution to combine an automation platform that can translate data across protocols with a worldwide team of engineering and operations professionals.

Launched in the fourth quarter of 2011, the new platform has quickly attracted the attention of corporate real estate leaders and the building automation industry. Several corporations have implemented the solution, sometimes starting with a pilot program at a handful of buildings and then on a larger portfolio basis after impressive initial results. For starters, normalized energy use has been shown to decrease by as much as 18 percent within six months of implementation, paying back the upfront cost of implementation within the first year.

IntelliCommand has been recognized for smart building innovation with

the Realcomm Digie award in the category of Best Use of Automation in

Facilities Management at Realcomm IBCon, a conference that brings

together professionals across the intelligent buildings industry, and

was also recognized in GreenBiz Group’s VERGE 25 Awards in the category

of Next-Gen Buildings.

The first facility management solution to offer 24/7, cloud-based remote monitoring and control of facilities, this solution optimizes energy efficiency by continual commissioning. Millions of data points from individual pieces of equipment across the portfolio are analyzed in real-time using complex algorithms and, when the system identifies an anomaly, it can often diagnose the cause and make adjustments to correct the problem.

When the automated system can’t make repairs on its own, it alerts professionals at a central command center in Somerset, New Jersey, which is staffed around the clock. Command center personnel dispatch an engineer or facility manager associated with the property for immediate action or a more convenient time, depending on the urgency of the issue. Through integration with the work order management system, the day-to-day interaction between onsite engineers and centralized portfolio managers is streamlined by enabling communication through a familiar, easy-to-use platform.

The synthesis of technology and human expertise ensures

that all systems operate at peak efficiency individually and in

combination with one another, fully leveraging the integration of

information from all inputs.

As an example of how it analyzes data, consider an air handler that circulates air to one floor of a building, heating or cooling air by passing it over a fan coil and using a damper to control the rate of air flow. By monitoring temperature and flow data from the air handler, the platform performs a continuous heat transfer analysis and adjusts the coil and damper to keep the system running at peak efficiency. If there is a degradation of the heat transfer that causes the components to work harder than they should, the algorithm can pinpoint the issue as originating from the coil, the damper or another component.

In one pilot project, as soon as IntelliCommand was installed and initialized, the facilities team found out that two air handlers were not using “free cooling,” air from the outside that could be mixed with circulated air to maintain the indoor temperature. The system was receiving an RSS feed on local temperatures and knew how much air should have been coming in; the fact that outside air was not being utilized pointed to a problem. Engineers found and repaired two broken dampers, which corrected the issue. Regular maintenance checks would not have caught the problem as quickly and perhaps not at all, since the building’s occupants were entirely comfortable. The existing BAC was simply using excess energy to cool air, costing the company thousands of dollars in unnecessary energy costs.

The system also detected that variable fan drives were running fans at high speeds all the time, rather than varying fan speeds to conditions as they are designed to do. To fix the problem, engineers changed temperature set points, which would have been presumed to resolve the issue under a normal maintenance program. But with IntelliCommand in place, it was immediately obvious that the fans were still running too fast. A second adjustment also failed to fix the problem. Only then did the team trace the issue back to a programming error in the original BAC software, a hard-to-find weakness that had gone undetected for the life of the building up to that point.

This example illustrates that benchmarking energy against historical usage is not enough to optimize performance. And the cost factor was significant: The power needed to turn a fan is a function of the speed cubed—in other words, a fan spinning twice as fast as necessary is not just using twice as much energy, but many times more than needed.

The ability to find these elusive inefficiencies drives the strong return on investment that owners are experiencing. After the initial payback period of less than a year, portfolio owners are realizing energy cost reductions that quickly return millions of dollars to the corporate bottom line. The platform is also scalable, so companies can start with a dozen or so properties to prove the concept before implementing across their entire portfolios.

This solution can also extend equipment life by ensuring that

maintenance and repairs are made when they’re needed. Since the failure

of one piece of equipment can often lead to additional breakdowns, the

early detection of potential problems promises to save nearly as much

on equipment and repair costs as on energy costs over the long term.

Data can be used in other ways as well. The software combines usage data with the resource mix of local utilities to calculate greenhouse gas emissions, simplifying the measurement of carbon footprint. And corporate real estate executives can do a better job of capital planning when they know which equipment and which buildings can benefit the most from upgrades.

[an error occurred while processing this directive] Another benefit—the potential to avoid critical equipment failures--may be far greater than the direct cost savings. Even a short-term loss of electrical power to a data center, manufacturing plant or other critical facility can cost a company more in lost revenue than it spends on energy in a year. Facility executives whose jobs could be on the line if a critical failure occurs may find it difficult to systems to prevent failures. Part of the appeal is that the cost can be rationalized by expense reduction, so risk mitigation can be considered a side benefit.

IntelliCommand is driven by technology from Pacific Controls Inc., which includes the ability to connect buildings with different automation protocols. Large corporations with many facilities around the world invariably have different automation systems in different places. The ability to build on the automation in place rather than installing all new systems represents a significant cost and time savings to companies that implement IntelliCommand.

The real value of the solution, however, is not only in its technology. Jones Lang LaSalle has a track record of success in energy management across large portfolios, having helped clients achieve energy savings totaling more than $100 million in each of the past several years. Elements of IntelliCommand, such as centralized control over portfolios and the ability to monitor data in easy-to-monitor graphs and charts, were part of JLL’s energy management program even before the solution was launched.

The combination of Pacific Controls technology and JLL’s facilities

expertise ensures that, as automation becomes more sophisticated and

industry best practices evolve, users of IntelliCommand will be among

the first companies to take advantage of emerging features and

possibilities. With more and more regions implementing smart grid

infrastructure, the worlds of building automation and energy management

are changing very quickly. IntelliCommand is designed to allow users to

stay at the forefront of new trends.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]