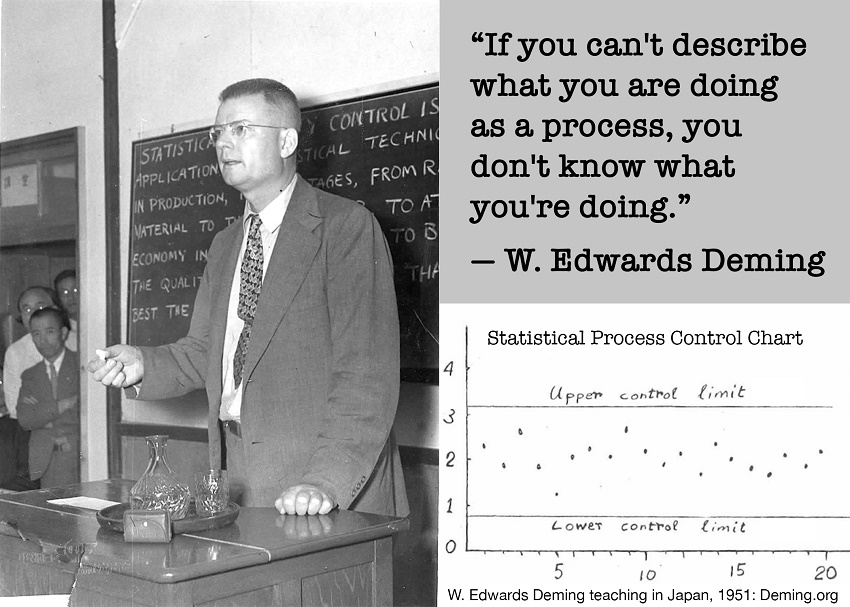

Today’s operational analytics, cyber security tools, and other business intelligence software are all ‘grandchildren’ of the statistical process control charts made popular by Deming.

Therese Sullivan,

Principal,

|

May 2017 |

[an error occurred while processing this directive] |

| Operational Analytics, Cyber Security Tools & the Deming Way Today’s operational analytics, cyber security tools, and other business intelligence software are all ‘grandchildren’ of the statistical process control charts made popular by Deming. |

Therese Sullivan, Principal, |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

The

corporate finance types that reason that building analytics projects

need to be justified by energy savings alone need to review the W. Edwards Deming story

in their business school textbooks. Deming’s name is synonymous with

the history of statistical process control — first in post-WW2 Japan,

and then back in the USA in the late 70s once American manufacturing

firms started losing market share to higher quality Japanese products.

Today’s operational analytics, cyber

security tools, and other business intelligence software are all

‘grandchildren’ of the statistical process control charts made popular

by Deming. In the 1950s and ‘60s, Deming’s approach was shunned by US

manufacturers who were more interested in Value-Engineering than

Quality --until Japanese competition gave them a rude awakening.

Value engineering is what is kicking many

building analytics projects off the table today. Decision makers that

would rather stay blind to the ‘slop’ in their buildings’ operational

processes and pay the price of wasted energy are following the same

logic as those pre-Deming American manufacturers that thought they

could live with processes that were creating 3% to 4% defective parts.

At the time, the cost of the materials and manpower that went into the

scrap seemed as easy to ignore as inflated energy spend—a small price

to pay for doing nothing about process control. Of course, now we know

that trying to inspect out bad parts was a fool’s errand. Bad

components infected the supply chain, led to bad products, ruined

customer relationships, tarnished brands, and eventually put companies

out of business.

Deming’s message was that investment in

quality and process control leads to a virtuous cycle of improvement in

products and market competitiveness. Owners might not think of their

buildings as processes that can be brought under control in an

industrial process control sense, but they would do well to brush up on

their Deming because the time is coming when they will be expected to

do just that. Organizations focused on consensus industry standards

like ISA, CSA, and CABA are busy defining what process control of a

building's lifecycle should be. And people have new social-media ways

to make their displeasure known when they are asked to live, work,

learn or heal in an environment with sub-standard temperature control,

lighting, air quality, and secure data.

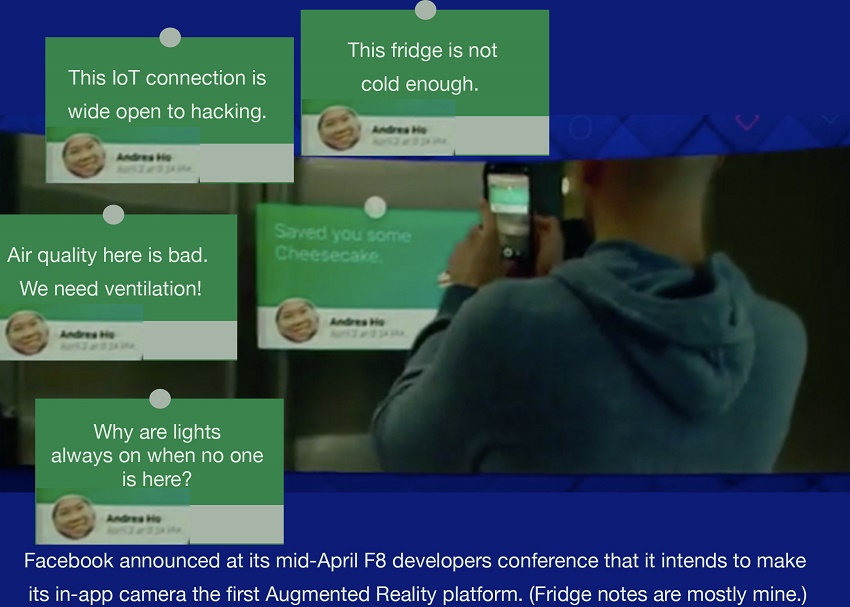

Facebook announced at its mid-April F8 developer's conference that it intends to make its in-app camera the first Augmented Reality platform. It is not waiting for AR glasses to be perfected. Occupants playing with the ‘fridge notes’ feature could become a facilities manager’s worst nightmare. Or property managers could get ahead of this feature and incorporate this mode of occupant feedback into their workflow processes. In Deming’s day, such an invitation to all stakeholders to participate in process improvement was called a Quality Circle.

Formal process control methodology starts

with having strong and up-to-date industry consensus on the right way

to do things. Events like the CABA Intelligent Buildings & Digital Home Forum

are where leaders gather to discuss current trends and research in

intelligent buildings. I was pleased to be part of this event last week

in Santa Clara, moderating a panel on Cyber Security & Analytics.

There Andre Ristaino, Managing Director of the ISA Automation Standards

Compliance Institute, made the point that cyber security is yet one

more quality dimension that must be controlled in the lifecycle of a

building. He also estimates that commercial buildings are about five to

six years behind other process industries regarding the deployment of

analytics platforms to get operational processes and cyber security

under tight control.

Standards-based product and lifecycle

process certification is the first step toward effective process

control. The ISASecure control systems certification program

strives to certify from the standpoint of the suppliers of commercial

off-the-shelf (COTS) systems, the integrators that combine those

systems into site-specific building control workflows, and the owners

who are responsible for operating and maintaining those assets and

workflows over their lifetime.

The big COTS suppliers of building

equipment are veterans of the quality movement of the last 50 years.

That’s why they are such giant, dominant forces today. For the most

part, their manufacturing processes are six sigma black belt level.

When a COTS supplier deploys cloud-based analytics for remote

monitoring, there is greater confidence that all aspects of the cyber

quality vector have been brought to state-of-the-art levels. For

example, I sat in on the Johnson Controls Smart Connected Chillers webinar

recently. The presenters listed the following as the vital security

factors to look for:

The COTS product level is not what frightens

building owners the most about deploying cloud-hosted analytics. Rather

it is when integrators deploy operational analytics at higher,

whole-building and whole campus levels. First, site-specific

integrators need two-way connectivity to create a feedback loop whereby

analytics results trigger automated adjustments to controls

programming. Still, the cyber security threat can be mitigated. Matt

Jakuc, Product Group Manager and technical lead for the cyber

security program at CSA Group, explained to the CABA Forum audience

that the design engineers and systems integrators responsible for

controls workflow design could be educated in how to do data handling

on par with state-of-the-art IT standards. Also, 3rd-party evaluators

like CSA are available to certify their work. So, fear of hackers

should not derail analytics projects. There is never ‘no risk’ with

Internet connectivity, but the benefit of tapping all the data that

could help get a building’s lifecycle under tight control is worth it.

Regarding that multiplicity of data sources

and all the quality vectors that need to be controlled in addition to

cyber security, this recent quote from Ruairi Barnwell, Energy Services Leader and Principal

of the building design firm DLR Group provides a good list:

“The new Key Performance Indicators (KPI) for building performance in addition to energy use intensity include indoor air quality, thermal comfort of occupants, visual comfort, acoustic comfort and user functionality. Our building owner clients don’t stop at wanting a dashboard for energy; they want visibility into these other factors too.”

Ruairi also

speaks to the challenge of doing data handling on par with

state-of-the-art IT and cyber security standards:

[an error occurred while processing this directive]A spokesperson for one of those building

data management, visualization, and analytics platforms was also on the

CABA Forum Cyber Security &

Analytics panel, Marc Petock of

Lynxspring and Connexx Energy. Marc spoke to the business implications

of ignoring cyber security. He concurred with other panelists that fear

of internet hacking and a focus on energy savings alone when doing

payback calculations are the two factors that have kept the buildings

industry years behind other markets in adopting more sophisticated

data-driven process control. He points out that hard data that

quantifies the degree to which a control system can impact occupant

health, and well-being has been hard to find, to date.

Yet, DLR Group puts it out there: ‘Our goal

is to elevate the human experience of buildings through smart building

design and controls strategies.’ That design firm is breaking down the

challenge into KPIs for its building owner clients, and it is going

about the job of quantifying the ‘fuzzy’ stuff.

It should be noted here that Process

Control guru, W. Edwards Deming never

said: “Only manage, what you can

measure.” The saying “You can only manage, what you can measure,” is

also a misquote. What he said was “It is wrong to suppose that if you

can’t measure it, you can’t manage it – a costly myth.” (Out of the

Crisis, pp 121-126). Perhaps those that argue you should only count

energy savings because that is the only thing you can easily measure

have fallen under the spell of one of the first two misreadings. Deming

is actually encouraging process managers to go further into the

unmeasurable. He continues, “The most important figures that one needs

for management are unknown or unknowable.”

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]