October

2008

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

October

2008 |

[an error occurred while processing this directive] |

|

|

Author "Smart Buildings" |

“There

seems to be some perverse human characteristic that likes to make easy things

difficult.”

Warren Buffet

One of the underpinnings of smart building technology is squeezing inefficiencies out of the installation and operation of building systems. At the physical level this means addressing equipment rooms, cabling and cable pathways. In fact, the largest opportunity to reduce capital costs of installation in building technology systems is the installation of the system’s cable and cable pathways. The way to facilitate this is to use one cable contractor for the systems, use as much structured cable as possible, and consolidate cable pathways. As an example at Ave Maria University, Bryan Mehaffey, VP for System Engineering, estimates that $1.5 million or about 40% was saved by using one cabling contractor and avoiding unnecessary and redundant cabling.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

Overview

In the 1980s many data processing systems had proprietary cabling,

that is, manufacturer specific cable for systems from IBM, DEC and Wang.

Structured cable was designed to be independent and handle different

applications such as voice and data, and equipment from different manufacturers.

The Category 5 or 6 cables which we all are generally familiar with are the

latest cables from a structured cable standard known as ANSI/TIA/EIA-568 A and B

Commercial Building Telecommunications Cabling Standard.

As more and more building technology systems evolve to IP and Ethernet, such as video surveillance, access control and lighting, structured cabling is incorporated in the installation. However, one area in which structured cable has not been significantly utilized is building automation systems, thus limiting how far one could converge the cabling plant in a smart building. What follows are some approaches major cable manufacturers have taken regarding the use of structured cable or BAS systems.

Structured Cable for BAS

Pushed to the side and almost swept under the rug is a standard

called ANSI/TIA/EIA-862 Building Automation Systems Cabling Standard for

Commercial Buildings. This standard is similar to the structured cable standard

for telecommunications. While it may be news to some, the standard was

established in 2002 and is currently under revision. Systimax, (at the time a

part of AT&T which also included the world renowned Bell Labs which supported

AT&T’s product line) was instrumental in creating the standard. Bell Labs’

research produced thousands of innovations and inventions including the

transistor, the laser, C-programming language, Unix, the first wireless LAN, the

first 56k modem, and TDMA and CDMA digital cellular telephone technology.

Systimax, a premier cable manufacturer, is now part of Commscope and an industry

leader in the utilization of the BAS structured cable standard.

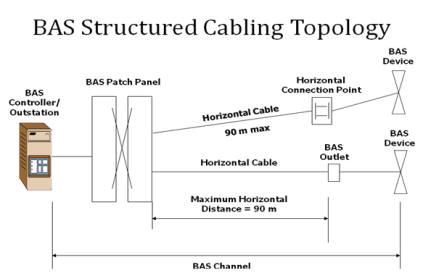

These

two standards, one for telecommunications and the other for building automation

systems, allow for a fully converged cable infrastructure in smart building

technology systems. Both the ANSI/TIA/EIA 568 and 862 standards require an open

cable infrastructure that is independent of any products and vendors. The

primary basis for both standards is the use of twisted pair copper and fiber

optic cable. Both standards have similar design guidelines (i.e the 90 meter

rule) and parameters for reliability, capacity and compatibility.

These

two standards, one for telecommunications and the other for building automation

systems, allow for a fully converged cable infrastructure in smart building

technology systems. Both the ANSI/TIA/EIA 568 and 862 standards require an open

cable infrastructure that is independent of any products and vendors. The

primary basis for both standards is the use of twisted pair copper and fiber

optic cable. Both standards have similar design guidelines (i.e the 90 meter

rule) and parameters for reliability, capacity and compatibility.

There are two minor differences between the BAS and telecommunications cabling standards. One is that the BAS standard refers to a “horizontal connection point (HCP)” which is similar to Telecom’s “consolidation points” or zone cabling. The second minor difference is the BAS Standard’s use of a “coverage area” as opposed to Telecom’s “work area”.

Using structured cable in a BAS environment is different than its use in a typical data network. The cable topology and the location of the end devices are different. More consideration has to be given to signal loss budgets, devices placed on a link or bus, and the cabling distances supported.

BAS devices are generally power limited. The current draw and line voltage delivered by the power supply for a BAS device usually limits the signal distance for devices. Typically, 24 AWG balanced twisted-pair cable has the capacity to handle 1 ampere (A) of current draw per conductor with a maximum of 3.3 A per 4-pair cable.

Some contractors think that the BAS devices require a larger gauge cable (18 AWG) than the smaller gauge cable of Category 5 or 6 structured cable (24 AWG). When you take a look at the electrical characteristics needed for the devices though, the larger diameter conductor cable is usually unnecessary. A typical category 5 cable has the capacity to handle 1 ampere (A) of current draw per conductor with a maximum of 3.3 A per 4-pair cable. If a 24 V BAS device requires 50 mA (0.05 A) of current to operate with an allowable voltage drop of 10%, the maximum circuit distance using Category 5 cable is around 840 feet. If a BAS device requires more current than can be delivered by structured cabling the device probably needs to be powered locally.

If you think that using structured cabling for BAS system will void warranties, think again. Catch up on your reading and take a look at the application guidelines for major manufacturers such as Carrier, Johnson Control, Siemens, Lonworks and others that were developed nine years ago.

[an error occurred while processing this directive]

Co-Existence

Another approach to infrastructure convergence is to use different

types of cable for BAS systems but to converge the cable pathways for BAS and

telecommunications systems. This approach still allows for cost benefits by

using one cabling contractor and efficiencies in consolidating cable pathways

but slightly diminishes the economics and functionality of using a full

structured cable deployment.

Panduit, another leading cabling manufacturer, has a BAS connector module that supports the typical low voltage and field bus networks used in BAS systems which can be used in standard IT patch panels and faceplates. This provides for BAS systems to utilize their own cable and cable termination types, allowing for similar pathways, equipment rooms and enclosures to be used for IT and BAS. In addition, Panduit provides zone enclosures, a network consolidation point similar to the Horizontal Connection Point in the ANSI/EIA/TIA 862 standard, which allows all cables to be managed and patched in a single enclosure.

Conclusion

With the financial metrics of the approach proven and the

availability of products and solutions from major manufacturers in the

marketplace one wonders why the approach is not the standard method of operation

for building owners, architects, engineers and general contractors. The excuses

are usually twofold:

“I have to put the wiring in myself. I can’t depend on another contractor to put in the wiring.” Cable contractors must provide test results on each pair of structured cable demonstrating that it works and meets standards. Typical structured cable installations provide more extensive testing than that done on any typical BAS cable.

“We’ve never done it that way.” I doubt a designer or contractor would want to be saying this to a building owner who may understand the construction cost implications of a structured cable system and wants it done his way not yours. Embrace the approach as offer it solutions and value to clients.

For more information about evaluating, creating and deploying smart building solutions, hardware and software technology design or to schedule a Continuing Education program for your office write me at jsinopoli@smart-buildings.com.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]