|

October 2014

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

|

Where do Whole-Building Analytics Fit

in the Energy Professional's Toolkit?

The need for building energy analysis is growing, the talent

pool of building energy experts is limited. New whole-building energy

performance assessment tools are one way technology innovators are

trying to fill the gap.

|

|

New York City just announced a building retrofit plan to move it

towards the goal of an 80 percent reduction in emissions by 2050.

As municipalities and states make such public commitments, the pressure

is on property owners to comply. This dynamic increases demand

for energy benchmarking, energy audits, energy savings estimates, new

construction and retrofit commissioning, among other activities related

to improving the energy efficiency and comfort of building stock.

Yet, while the need for building energy analysis is growing, the talent

pool of building energy experts is limited. New whole-building energy

performance assessment tools are one way technology innovators are

trying to fill the gap.

Looking at any system from a high-level and as a whole is usually the

best way to get to know its key drivers. The ability to assess energy

performance of whole buildings through a quick data analysis would

certainly be welcome. But, can you extract sufficient information for

business decisions regarding the prioritization Energy Conservation

Measures (ECMs) in this way, given the idiosyncrasies and well-hidden

features of commercial buildings? Answering this question affirmatively

by improving the contributing technologies has been a challenge

embraced by innovators of all stripes. Here is a list to help you sort

the field:

- Model-Based Building Performance Analysis tools that have evolved

as extensions of building information modeling (BIM) tool suites

familiar to architects, engineers and contractors

- Meter and Sensor-Based Remote Building Performance Analytics

coming from new ‘Big Data’ start-ups that are being packaged into

Utility-run energy efficiency programs

- Model-Based Building Performance Diagnostics that productize the

latest Building Science emerging from university programs and research

organizations

- Real-time Operational-Data-Based Building Performance Diagnostics

that plug directly into Building Management Systems (BMS) to gather

data and are thus more of an extension of Building Automation and

Control

The value of the recommendations output

by any of these category of tools is inevitably compared to the

recommended ECMs that come from conventional engineering calculation

approaches.

The Association of Energy Services Professionals (AESP) recently

invited speakers from PG&E, Autodesk and First Fuel among others to

address continuous learners on the topic of software analytics tools

that attempt to remotely assess whole-building energy

performance. This session was captured and is available with slides

and audio here. Based on this

information, plus recent conversations

with commissioning experts familiar with operational building

analytics, here is an overview of how each category is being deployed

today and how the categories might evolve to fill out the energy

professionals’ toolkit.

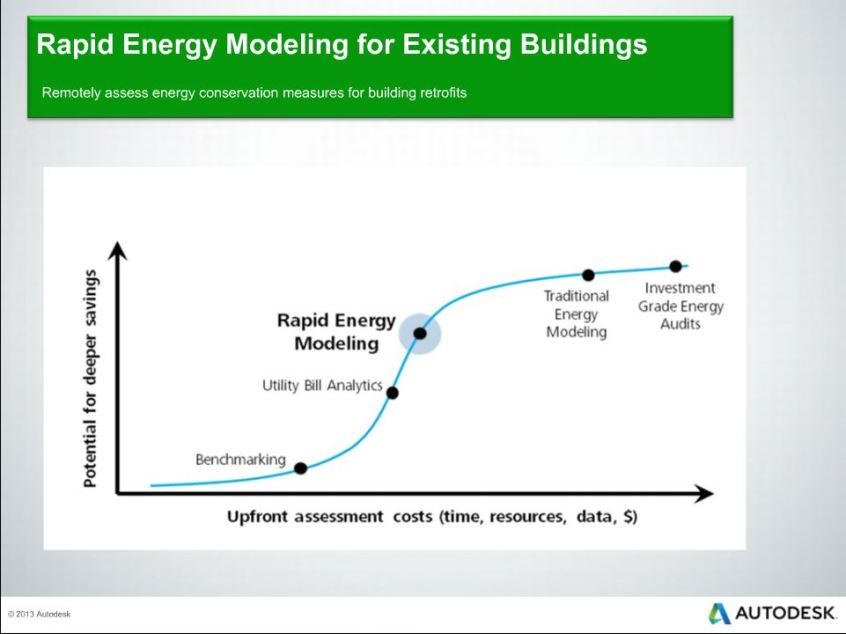

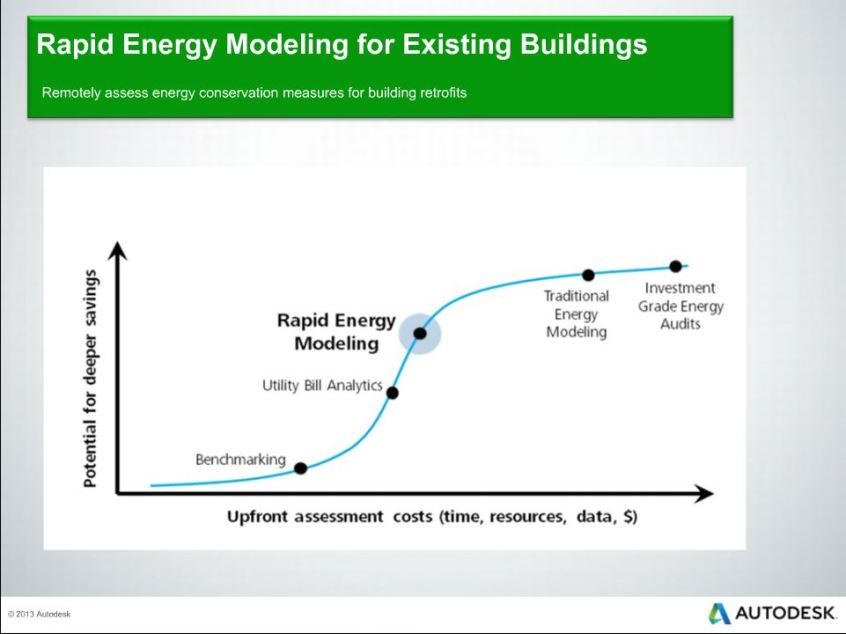

Model-Based

Building Performance Analysis

Building information modeling (BIM) and

advanced simulation approaches like those possible with Autodesk’s

Revit are being used for energy assessments and audits, as well as to

drive deeper energy retrofits. Autodesk’s Aniruddha Deodhar

explained that energy conservation measures recommended by this

modeling approach extend into design changes like daylight controls,

insulation, window upgrades etc. Such fundamental design changes

in the building offer the potential of greater energy savings, than

operational (adjust setpoints) or behavioral (encourage occupants to

turn off lights when not used, e.g.) ECMs alone. Autodesk’s Rapid

Energy Modeling method uses capture options like satellite and aerial

images, photos, drawings, laser measuring, plus basic building data

gleaned directly from Revit building information models.

Autodesk has been working on ease-of-use

of its sophisticated modeling software that evolved to meet the 3D CAD

needs of architects, structural engineers, MEP engineers, designers and

contractors. In the case of Rapid Energy Modeling, Autodesk’s Deodhar

explained that the toolset was designed to be simple enough for a

high-school student to use, which is key due to the scarcity of

graduated energy engineering talent. He pointed out that the models

incorporate the findings of energy savings sensitivity studies for 12

common building types.

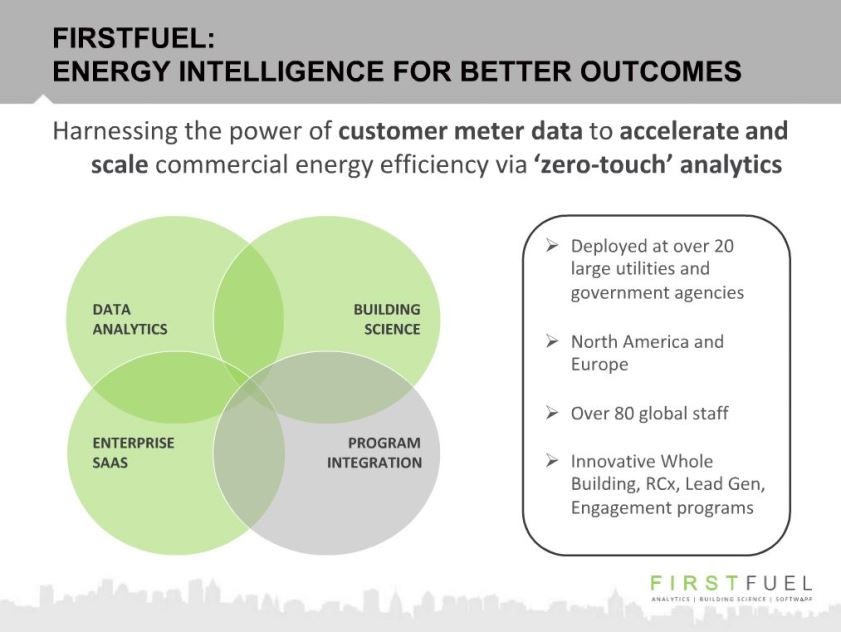

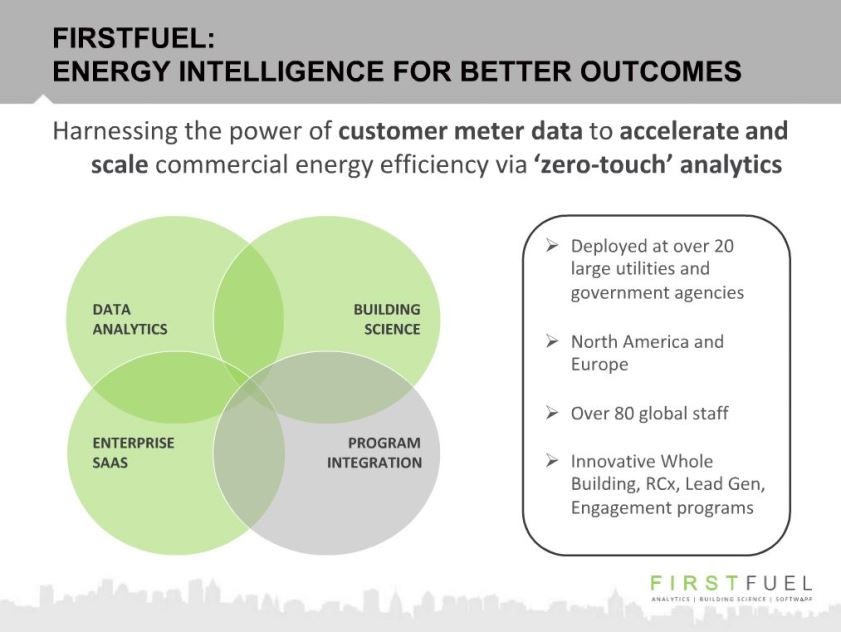

Meter/Sensor-Based Remote Building

Energy Performance Analytics

First Fuel uses meter data, mapping

tools, weather data and occupancy data to model a commercial building’s

energy performance. The venture-funded company provides energy auditing

services to commercial building owners that are typically packaged and

delivered through

utility partners. Utility partners

use First Fuel’s cloud-based ‘zero touch’ energy assessment tools for

customer engagement and motivation, as well as to enable performance

tracking and regulatory measurement and verification.

One PG&E Emerging Technology program

offers commercial facilities of greater than 50kW in electric demand

the opportunity to find energy savings opportunities using analytics

software provided by First

Fuel and C3.

With the expectation of over 15% post-installation energy savings,

participants are offered an upfront incentive and a performance

incentive tied directly to achieved savings through implementing the

retrofit, as well as operational and behavior efficiency measures

suggested by these in-the-cloud tools.

Hierarchical Modeling and

AFDD-Based Building Performance Diagnostics

The team at KGS Buildings makes a compelling case for a modeling

approach to whole-building energy assessment that also supports a

continuous and connected process as you move up and down through a

building system hierarchy. Diagnosing a detected anomaly, for

example, can require examining operational efficiency of the HVAC

system as a whole, then a series of VAV's all connected to one AHU,

then an individual AHU or an individual VAV, etc. Sometimes

called hierarchical rule-based FDD, or monitoring-based commissioning

(MBCx), software suites like KGS

Clockworks™ have a Fault Detection and Diagnostics (FDD) knowledge

base at the core with decades of accumulated performance data, made

accessible with the latest data search methods. They can provide

an enterprise view across multiple buildings and multiple building

automation system platforms down to individual equipment by comparing

data collected from each facility to its library of diagnostic code

data. Clockworks' library incorporates cooperative research and

development with Pacific Northwest National Laboratory (PNNL) on

diagnostics for outdoor air economizers and whole buildings as well as

retuning algorithms that identify operational inefficiences leading to

comfort and maintenance problems and excess energy consumption. A

book on the topic, entitled Automated Diagnostics and Analytics for

Buildings, has just been released by authors from PNNL and the

University of Florida.

As KGS Partner, Nicholas Gayeski, explains in a recent whitepaper, “A

central challenge for Automated FDD is the need to deploy diagnostics

across many different building profiles, systems and types of

equipment. Effective solutions must avoid re-writing diagnostics with

every new building, which is cost prohibitive, while at the same time

avoid false positives. Clockworks™ addresses both of these two

priorities with a centrally managed code set that is customized to

individual facilities through a scalable software configuration

architecture that enables rapid deployment. This means that a complete

library of diagnostic code can be rapidly applied to individual

buildings, entire campuses or even large building portfolios by mapping

point, equipment and system parameters directly into an internal online

tool that augments the central diagnostic code without re-inventing the

wheel. This is referred to as mass-customization."

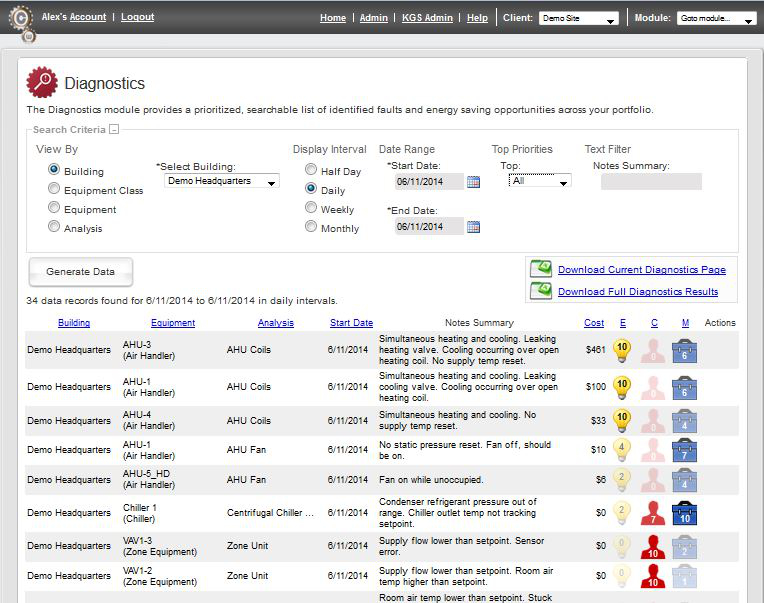

Caption:

Clockworks™ prioritizes the results by energy cost, as well as comfort

and maintenance on a 0-10 scale. All results from equipment and system

level analyses appear in the punchlist that you see above according to

the date range selected. This list can be sorted by portfolio or

individual building, as well as equipment class and type of analyses.

This allows a user to drill into a specific building, piece of

equipment, or type of analysis. The figure above illustrates the

results of diagnostics across a portfolio with a daily interval of 24

hours.

Real-Time Operational-Data-Based

Building Performance Diagnostics

The Connected Building Commissioning

process of Energy Engineering services firm, Altura

Associates, exemplifies yet another approach to

whole-building/whole-portfolio energy assessment. This involves on-site

connection to the building management system (BMS) to extract realtime

data from thousands of measured HVAC, water and lighting points and

feeding this to the cloud-based SkySpark™ fault detection and analytics

platform from SkyFoundry.

From this diagnostic scan, a detailed set of building system-specific

rules is extracted. This results in a fast and deep understanding of

systems performance and the discovery of improvement opportunities.

Altura’s Matt Schwartz is using this

Connected Building Commissioning process for client Pacific Medical

Buildings (PMB) of Southern California. Early program results have

delivered energy cost savings of over 20% per building, representing

annual cost savings of more than $65,000 across just two buildings.

According to Schwartz, “Analytics is not a box that sits on the

wall. You cannot get the job done front-to-back with a hands-off

remote approach. By plugging right into the BMS, we’re not working on

‘Big Data,’ as much as working on the ‘Right Data’. Our mix of

onsite engagement plus cloud analytics includes meeting with staff and

tenants so we understand the ‘people’ component. With this

combination, we’ve been able to knock these assessments out

building-by-building, at an investment on the part of our client that

is relatively low, while returns are high.

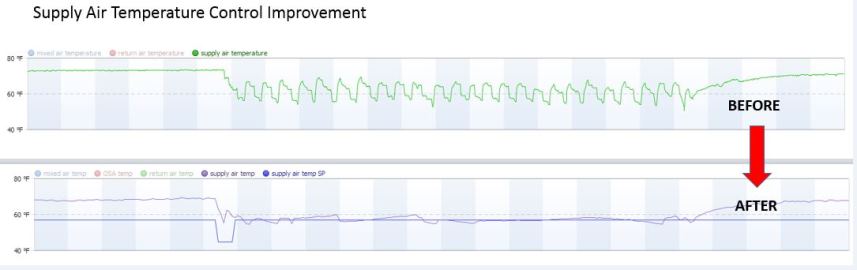

Caption:

Before and After Supply Air Temperature Control. Note the significant

cycling of supply air temperature from the unit before the changes. As

a result of the improvements, occupant comfort is greatly improved and

the lifetime of compressors is extended.

The CBCx process has allowed the team to uncover issues which might

otherwise have gone unnoticed, or been deemed too time consuming to

troubleshoot. The SkySpark visualizations above reveal how a rooftop

HVAC system for one of the facilities was experiencing a high frequency

of cycling due to poor system tuning and control. With a

relatively simple fix (new control logic and tuning parameters), the

system was tuned and tested to decrease the cycling frequency. As a

result, the equipment is now at a much lower risk of failure, comfort

control is improved, and operational costs were significantly reduced.

Conclusion

[an error occurred while processing this directive]

There are many other companies entering the fray when it comes to

software for quickly finding the best opportunities for operational

savings across a whole building or portfolio - and, finding

worthwhile design upgrades like building envelope or lighting

changes. Questions to ask when reviewing offerings include:

- How does the solution integrate with multiple building automation

system platforms?

- Can the assessment method scale across the targeted portfolio?

- What activities are cloud-based versus on-site?

- How does the solution handle the various human-factor facets of

the challenge?

- Will the software offer design upgrade suggestions like changes

to the building envelope and lighting design?

Then don’t spend too much time analyzing

before diving in because, by tomorrow, each of these categories will

have evolved and merged in ways we haven’t thought of yet.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]