April 2006

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

April 2006 |

[an error occurred while processing this directive] |

|

|

Mark Rizkallah Paul J. Celauro |

Systems integrators are becoming excited about a technology that can significantly increase their value-added opportunities and bottom line performance. The concept, called Early Detection Loss Prevention, is made possible by a unique temperature detecting system that alerts asset operators to abnormal temperature events that can cause damage and often precede the outbreak of a fire. Alerts summon occupants to investigate and avert the situation long before it leads to damage losses.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

“It augments the protection of high value assets because it detects abnormal temperature events long before fire alarm and extinguishing systems come into play. Sometimes there isn’t smoke to detect in a given situation until there is an open flame, yet the telltale temperature excursion has been advancing for hours in an overheating piece of equipment, or in wiring and cables,” says Paul J. Celauro, Director of Industry Solutions for Neurologic Research Corporation.

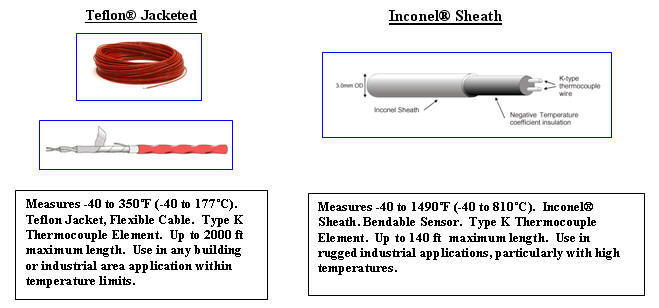

The system employs a unique linear real-time temperature sensor element that can be up to 2000 feet long per segment. It transmits the highest temperature sensed anywhere along its length. The Teflon® -jacketed version will detect any temperature between -40 and 350 degrees F, and the Inconel®-sheathed version detects between -40 and 1490 degrees F. The system electronics use specialized algorithms to detect an abnormal event, and can communicate resultant alerts in a wide variety of formats including lights, audibles, electrical outputs, as well as via pagers, messaging, automated phone calls, and even the Internet. It will directly interface to most existing building automation systems.

“Designing and installing these one-of-a-kind systems represent a tremendous opportunity to add value to building automation projects,” cites Celauro, “and in this ultra-competitive market, a pathway to increased earnings for systems integrators.”

Many Architectural Applications

The system’s broad temperature range, continuous real-time measurement, and variety of output options readily lend them to a wide variety of architectural venues. Any temperature event within the range of -40 and 350º F (-40 to 177º C) can be defined as abnormal and warranting alert and investigation of the specific area of the facility.

This is particularly useful for cold storage areas for food, pharmaceutical, or blood banks, photo development, chip manufacturing, or sensitive chemicals storage, and other critical temperature zones where product damage or equipment damage could occur.

“It

is so important to detect abnormal temperature events in their infancy rather

than to wait until the sprinklers go off,” cites Mark Rizkallah, President of

Neurologic Research Corporation. “The loss has occurred by then, whatever is

being protected is waterlogged besides being burned, and all of it is so easily

averted with this system.”

“It

is so important to detect abnormal temperature events in their infancy rather

than to wait until the sprinklers go off,” cites Mark Rizkallah, President of

Neurologic Research Corporation. “The loss has occurred by then, whatever is

being protected is waterlogged besides being burned, and all of it is so easily

averted with this system.”

Resorts and hotels benefit from Early Detection Loss Prevention by alerting operators to hot spots that may lead to fires.

Any location containing irreplaceable assets such as art, books, archives, and rare artifacts is especially vulnerable to damage – museums, libraries, and universities need early alerts to abnormal temperature events before fires break out and resulting water sprinkling come into play, resulting in total losses.

Other applications include: Airports, Warehouses, Storage Facilities, Cold Storage, Utility Areas, Universities-Schools, Research Facilities, Laboratories, Military Facilities, Hospitals, Medical Facilities, Blood Banks, Zoos, Hotels and Motels, Resorts, Aerospace Facilities, Security Facilities, Public Buildings, Greenhouses Apartments, Condominiums, Convention Centers, Studios, Arenas, Restaurants, Wine Cellars, Theme Parks, Shopping Malls.

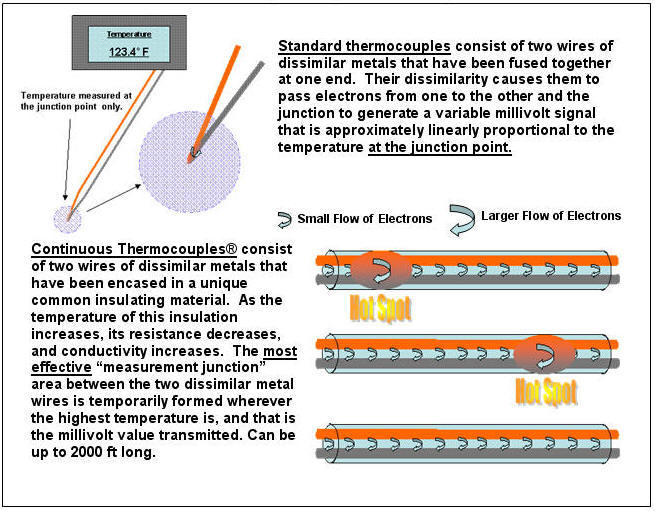

The Continuous Thermocouple® Temperature Monitoring System is made possible by a unique linear temperature-measuring element that can be up to 2000 feet long. Two versions of the element, Teflon® Jacketed ( -40 and 350º F), and Inconel® Sheath, (-40 and 1490º F), allow for continuous real-time temperature measurement that can be monitored, displayed, alerted, alarmed or transmitted over digital networks. The key to understanding how the sensor works is based on the difference between a standard point thermocouple and the Continuous Thermocouple®.

How is the Continuous Thermocouple® Temperature Sensing Element Different?

Early Detection Loss Prevention

Early Detection Loss Prevention is achievable and practical with CTTMS. A variety of progressive alarm conditions including configurable fixed-point alarms, rate-of-change alarms, and associated Boolean logic, can be configured to the precise application. The system can deliver all of this information in a wide variety of ways to advise users in the best ways to serve their needs. Data and alarm condition output formats include the following: 4-20 mA, contact closures, alarm lights, LonWorks®, Modbus®, Ethernet®, Internet, and more.

Early Detection Loss Prevention Sequence of Events

Expanded Business Opportunities for Integrators

Two types of sensor element (see below) and a number of output and system configurations provide a wide range of application opportunities for building automation systems integrators and installers to implement these value-added systems. Systems Designers and Integrators are able to expand their markets to new and new types of customers. On each project they can realize a better return for their efforts because of the uniqueness of this system and its functions. It provides protection for high-value and irreplaceable assets that does not exist today.

Flexible electronics outputs include lights, contact closures, and LonWorks®, making it easy to incorporate into standard building automation systems. 4-20 mA, Modbus®, Ethernet®, Internet, paging, messages are also available for integration into the simplest or most sophisticated systems.

“We’ve included a powerful set of communications tools to allow the integrator to easily bring this valuable Early Detection Loss Prevention technology into the kinds of buildings they like to work with, and increase the value of their offerings to their customers”, according to Rizkallah.

For the complete White Paper on Early Detection Loss

Prevention:

http://www.neurologic-research.com/Datasheets/MK-10205_A_White%20Paper_pg1-4_letter.pdf

For more information on the Continuous Thermocouple®

Temperature Monitoring System:

http://www.neurologic-research.com/Datasheets/BR-10185-2_A_CT%20Brochure%20pg1-2_letter.pdf

About the Authors

Mark Rizkallah is Founder and President of Neurologic Research Corp. Mark has vast experience in developing and manufacturing innovative sensors and systems that communicate interactively amongst themselves as well as with computers, networks, and the Internet. These systems are in widespread use today controlling and protecting many different types of assets in venues including Industrial, Telecommunications, Military, Transportation, Buildings of all types, and Law Enforcement. Neurologic Research is located in Orange, California.

Paul J. Celauro is Director of Industry Solutions for Neurologic Research Corp. Paul holds 6 U.S. Patents in a number of areas including water processing, safety apparatus for laser surgery, and systems for protecting electronics in extremely hostile environments. He has developed and successfully implemented large scale data acquisition and control systems that focus on loss prevention, safety, and optimization in a number of areas including the Food, Pharmaceutical, Water and Wastewater, Power Generation, and Medical Device Segments. Paul resides in Florida.