August 2007

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

August 2007 |

[an error occurred while processing this directive] |

“Technological change is like an axe in the hands of a pathological criminal.” Albert Einstein |

Jim Sinopoli PE, RCDD Author of "Smart Buildings" |

For all of the data and information created and developed during the design and construction of a building, very little of it is used in the operation and management of the building. It’s not that the information and data would not be useful, but rather that much of the data is created in a static, legacy paper format. That makes it difficult if not impossible to use the data in facility operations, property management or business systems, unless one decides to undertake the laborious task of manually entering data.

Lack

of data and information severely hampers the operation and management of a

building, diminishing operational effectiveness, efficiencies and productivity.

How bad are the inefficiencies and lack of interoperable data? Three years ago,

the United States National Institute of Standards and Technology issued a report

and “estimated $15.8 billion as the annual cost burden due to inadequate

interoperability in the capital facilities segment of the U.S. construction

industry. $6.7 billion of the total was due to inefficiencies in the design and

construction phases of the project delivery process.” That was a conservative

estimate.

Lack

of data and information severely hampers the operation and management of a

building, diminishing operational effectiveness, efficiencies and productivity.

How bad are the inefficiencies and lack of interoperable data? Three years ago,

the United States National Institute of Standards and Technology issued a report

and “estimated $15.8 billion as the annual cost burden due to inadequate

interoperability in the capital facilities segment of the U.S. construction

industry. $6.7 billion of the total was due to inefficiencies in the design and

construction phases of the project delivery process.” That was a conservative

estimate.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

The lack of useable data from the design and construction process impacts several “upstream” management systems. For facility management it involves systems for work orders, predictive maintenance, fleet management, inventory of materials and equipment, and energy management. For business systems it includes asset management (which has taken on new meaning as related to Sarbanes Oxley), purchasing, human resources, and other aspects of an Enterprise Resource Planning system. At a minimum, one needs to integrate the building systems, the facility management systems and some business systems. Beyond that initial integration, are other, more global systems that have a potential need for integration: property management, real estate portfolio management, etc.

None of that integration can occur without interoperable data, and little data will be available if the owner has to manually enter data into the system after occupancy. Obviously, if we had the information in electronic format when the asset was delivered, installed or commissioned, the accuracy and comprehensiveness of the database would be much improved. Such a database foundation would ease system integration, resulting in the functionality, efficiencies and cost advantages that integration can deliver.

How do we get there? What follows is an overview of the information created during construction, a “starter kit” of tools which could be adopted today, and the emerging framework of digitizing the design and construction process.

The Earth is Flat: Design and Construction Data

There are three progressions or events in the design and construction

process where key data is created or provided:

Construction Documents – These are crucial documents, with legal standing, that layout in a narrative and graphic format the requirements of the owner. The specifications, done in a version of the CSI’s MasterFormat, define the products, materials and workmanship required. The drawings show quantities, graphic representations and relationships of the elements in the construction. These documents represent the specific requirements of the owner as interpreted and refined by the architect and engineers.

Construction Process– Several documents are created during the construction by the contractor, subcontractor, suppliers, and manufacturers. These include shop drawings, coordination drawings, product data, samples, test reports, requests for information, construction change directives and plans.

Construction Closeout – These include record documents, addenda, field orders, change orders, spare parts and maintenance materials, warranties and commissioning documentation.

The vast majority of the documents created during the design and construction phase use word processing and CAD programs and is distributed via 8.5” by 11” paper and sheets of drawings. Of course, much of this is distributed via e-mail or posted on a FTP site, but little of it is used or in a format to be used with the facility management or business systems of the owner.

Starter Kit

Short of using Building Information Modeling (BIM) there are a handful of

things that can be done to facilitate the gathering of electronic data and the

integration of systems. Here are a couple ideas:

Have the contractors submit their product data electronically, such as electronic copies of the manufacturer’s specification sheets (in Adobe PDF), for each component delivered, installed, inventoried or made part of construction. These may not be in a database format, but they can be stored in a data management application, typically a software module in some of the better facility management systems.

Have the contractors also provide a listing of the product data in electronic format (such as Microsoft Excel) and have it include item numbers, descriptions, item model numbers, order numbers, skew numbers, unit cost, preventative maintenance schedule, warranty and life cycle.

Have the contractors supply the Operations and Maintenance manuals in Microsoft Word or Adobe PDF.

Prior to construction develop a labeling scheme for all the equipment and assets. Have the contractors use the scheme on all submitted drawings, from shop drawings through as-built drawings. Naming conventions are especially important for campus environments and large real estate portfolios.

Require that the administrative software for each building system utilize an open database, compliant with SQL and ODBC, such that it can share and retrieve information from other SQL and ODBC databases.

Use a Real Time Location Systems (RTLS) to track the building’s assets. The “legacy” method of tracking, bar codes, can’t be changed, need a line-of-sight to be read, have a short lifespan and offer minimal security. Use of a wireless system (Wi-Fi, RFID, and Zigbee) offers greater data capacities, better security, and can be read without line-of-sight or contact.

[an error occurred while processing this directive]

Building Information Model (BIM)

BIM is the future of building design and construction. BIM is a 3-D,

object-oriented, computer-aided-design approach for architects and engineers.

It’s been around for about four years. A few architects have used it for complex

projects. It’s just starting to get some real traction with new products coming

to the marketplace. One of the most valuable potential functions of BIM is its

ability to improve the coordination between multiple design disciplines, thus

reducing errors. BIM has the potential to respond to an owner’s need for

predictable costs, quality and on time delivery.

The American Institute of Architects has called BIM a “model-based technology linked with a database of project information”. It can store complete information about a building, including things like the quantities and properties of building components, in a digital format. It covers geospatial information and relationships about a building and facilitates the digital exchange and interoperability of the data. It appears as if BIM will use the Industry Foundation Classes (IFC) for exchanging information about a building project between different CAD packages. XML, an internet language, which allows raw data to be reliably shared over the Web, will also be utilized in BIM implementations.

BIM has the potential to be the vehicle or depository for use by the design team, the contractors and the owner, with each party having the capability to add their own data and information to the model.

A National BIM Standard (NBIMS) is being developed, and major vendors such as Bentley Systems, AutoDesk and Graphisoft have endorsed and supported the effort. Further information on BIM can be obtained at www.facilityinformationcouncil.org.

Prediction

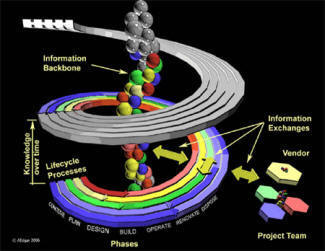

In the not too distant future, design and construction projects will require

an Information Manager. This entity will set the requirements for data

management for the owner’s project team, the design team and construction

contractors, manage the “supply chain” of data from design to construction to

operations, and manage the integration of the data from the building and

building systems into the owner’s facility management and business systems. The

drivers are the economics, the technology, the increased functionality and the

overall value proposition. That’s where we’re headed.

For more information about smart buildings, technology design or to schedule a Continuing Education program for your office write us at info@smart-buildings.com

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]