February 2009

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

February 2009 |

[an error occurred while processing this directive] |

|

To realize peak avoidance and enjoy significant associated savings, customers must know both when and where power and energy were consumed. |

Roland Acra |

The increasing level of scrutiny on energy consumption in business environments demands a detailed and ongoing understanding of the patterns of current energy consumption levels and a way to identify opportunities for increased efficiency. Networked sensors and a new generation of measurement and verification tools can play a huge role in gaining the necessary insights and implementing the most efficient and sustained energy strategies.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

The Main Drivers of Energy Awareness

Whether in single-tenant buildings and or multi-tenant properties, in commercial, industrial or institutional contexts, users are increasingly facing questions about the energy impact of running their facilities and business processes. Their goal: knowledge that will let them take action toward improved energy efficiency and reductions from past baselines.

The drivers of such energy awareness and efficiency improvements fall into four general categories:

- Financial savings: the powerful motivator for reducing energy-related expenses – or at least keeping them from growing – while increasing activity levels at a given site. Whether this translates into increased factory production or retail business, or more effective use of a data center computing facilities, the requirement is to "do more with less" in terms of "business output" as a function of "energy input." The critical factors influencing the financial impact of energy consumption are captured by utility billing mechanisms that include incentives and rebates, on the one hand, and penalties and prohibitive rates, on the other.

- Capacity limitations: in many instances, especially in large urban centers, the local electric utility's ability to bring additional power is limited. This is especially true of sites that start with very dense energy usage patterns in the first place, such as large-scale data centers or telecommunications central offices. When a site is compelled to grow its "output" with no option of power increase on the "input" side, the question of efficiency improvement becomes one of survival at that site versus relocation to another site where additional power requirements can be met.

- Regulatory mandates: Federal, state and city mandates are becoming increasingly binding on businesses and public institutions. While the upcoming "carbon cap and trade" scheme is the most well publicized and pervasive, more focused mandates will target government buildings and public activity centers in binding and time-based ways. Such mandates commonly require demonstrating reduced energy usage levels from a past baseline to a target future time. In another, more challenging, scenario, one-time improvements are insufficient for ongoing compliance, and continuous improvements year-over-year are required.

- Public image considerations: many businesses and public institutions are increasingly mindful of their image with their local community, their customer constituency, their investor base or even their current and prospective employees.

Views in Time and Space: Benefits of Networked

Sub-Metering

With these considerations in mind, facilities managers and financial executives

turn to the question of the measurement, monitoring and tracking infrastructure

required to "do more with less" in a way that enables ongoing and sustained

improvements in energy efficiency.

While many insights can be gained by "data mining" of past utility bills and awareness of aggregate consumption at the end of each billing period, realizing maximum savings may require additional instrumentation within a building.

First, customers need to understand where in a facility the components of the aggregate energy consumption occurred. They can deploy "sub-metering" instrumentation on electric sub-circuits that branch off the mains from the utility. By following the electrical circuit "branching" and measuring electric consumption down each sub-branch, they can disaggregate energy consumption into its constituent "spatial" or "functional" components: a given floor or an engineering lab or even the lighting system. Such visibility can be achieved at some manpower cost by walking around and reading the sub-meters' displays weekly or monthly.

More important, however, utility tariffs are highly sensitive to the patterns in time along which energy was consumed. Often a major component of energy cost is related to power demand, defined as instantaneous levels of electric load (in watts), rather than just to aggregate energy used over the billing period (in watt-hours). In particular, billing is highly focused on demand placed on the grid during peak periods of the day (e.g., warm afternoon hours) and the year (hot seasons), with long-lasting effects from past peaks due to utility demand "ratchet" billing mechanisms.

To realize peak avoidance and enjoy significant associated savings, customers must know both when and where power and energy were consumed. This time-based disaggregation of energy usage, which provides visibility into the patterns of load placed on the grid, can be achieved only through continuous and time-indexed readings of power consumption. Networked sub-metering, the most effective way of doing this, provides an "always on" set of sub-meters that can be programmed for what to read and at what frequency; the sub-meters then can be remotely read through an in-building network.

Once a customer knows where and when power was drawn and energy consumed, and how energy has peaked and ebbed in the facility over the hours and days (and takes into account utility time-of-use tariff structures and demand-response curtailment incentive programs), he has a rich picture of the key areas on which he should focus to achieve savings or take advantage of incentives.

[an error occurred while processing this directive] Performing at Industry Standards of Efficiency:

Networked Sensing

In-building energy usage can be apportioned to a set of building processes that

are common to many buildings (e.g., lighting, air quality, HVAC) and to a set of

specific processes that vary from business to business (e.g., engineering labs,

data centers, manufacturing floors, injection molding lines).

The extent to which "energy input" is leveraged towards a "functional output" can be referred to as "efficiency." For example, the amount of instantaneous power or time-aggregated energy used by an HVAC system to keep a room of a given size at some target indoor temperature, all the while knowing the outside temperature, yields one measure of how efficient the HVAC system is, compared to the latest industry standards defined by, say, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

Similarly, the amount of electricity used to produce desired lighting levels in an office space of a given size yields a measure of a lighting system's efficiency compared to the latest standards of energy-efficient lighting systems.

Yet another example can be seen when measuring the total electric input necessary to keep 1,000 servers in a data center powered and properly cooled for reliable operation. Such measurements can define the energy efficiency of the servers themselves (the amount of power used to keep them humming and evacuate the heat they produce).

For all such cases, networked sensors in the form of networked thermostats or ambient light sensors are critical to the benchmarking of business processes, highlighting deviations from expected optimal operation or industry-best standards, pinpointing faults that require maintenance actions, etc.

Achieving Business-Driven Effectiveness: More Networked Sensing

There is another, even more relevant, measure of how well the "energy input" is being leveraged towards a "business output." This additional measure is the "effectiveness" of the process. At stake here is the use of networked sensors to realize additional context that helps benchmark the output of the lighting or heating/cooling or computer-powering process relative to its business or health or safety effectiveness.

Using motion or occupancy sensors to control lighting systems is one example. With such sensors, a lighting system of a given level of efficiency (defined as lumens of functional output per watts of power input) becomes far more effective in serving its goals of human safety and productivity (the business output) than if it were lighting an unoccupied space for an extended period. Similarly, the use of CO2 sensors and occupancy sensors to control the rate of air renewal in a facility adds important context beyond the renewal rates set per regulatory standards without reference to actual human occupancy.

Even in business-specific processes, such context enhancements can be highly valuable in moving beyond efficiency alone to real business effectiveness. In the 1,000-server data center example, the added context of true offered computing load can calibrate a given data center as highly effective (if servers are powered down when the offered computing load is low) or highly ineffective (if servers are fully powered yet idle for sustained periods of time).

The more dynamic the context around a building or business process, and the more opportunity for variability in operating the lighting/heating/computing/injection-molding processes (through use of zoning, variable-speed drives, dampers, dimmers, virtualized servers, etc.), the more useful distributed, networked sensors prove to be.

Facility energy management using networked sensors

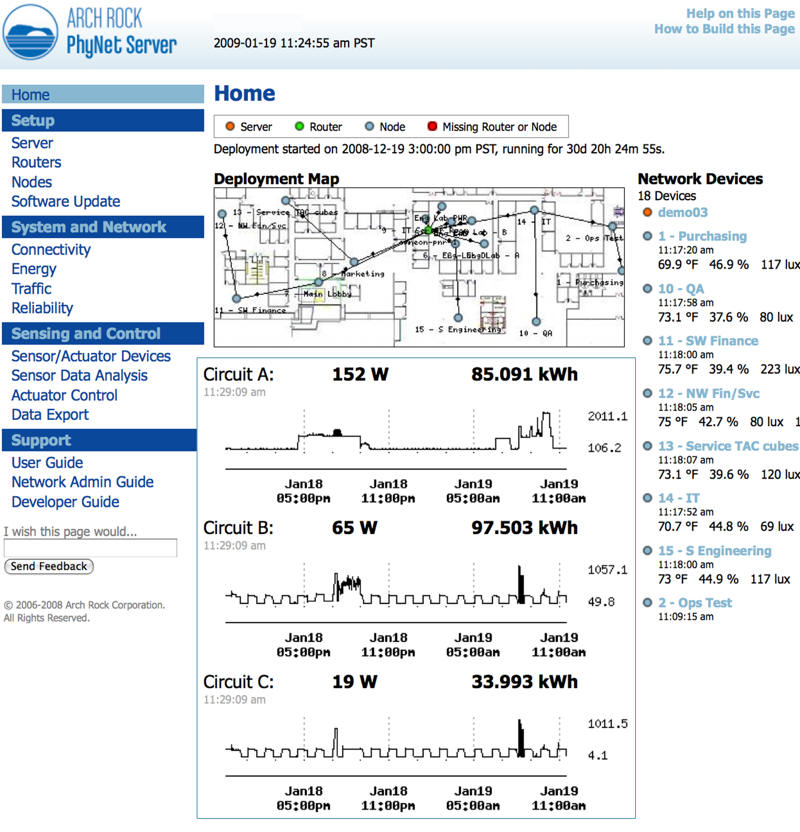

Example of building data acquisition dashboard, with site map and view of sensor mesh at center. Instantaneous environmental sensor data for each location are summarized at right. Inset shows per-circuit power draw for three circuits over the past 24 hours, as well as total power used in KWh. Of note are power peaks on two circuits, which non-networked sub-metering would have likely missed.

Retrofitting and Future-Proofing: Wireless, Internet Protocols and Web Services

Having made the case for always-on, networked sub-metering and context-enhancing sensing, we now turn to the question of flexibility of the data models and networking technologies being used to interconnect the sensors and actuators, and the central management and control systems that help drive their operations.

Starting with the "data" or application layers, the need to combine legacy systems with new systems, across several communication media and vendor products, drives the need for a coherent framework through which distributed systems can exchange data, query each other's readings, send control commands, etc. The modern framework for such data exchange and remote calling models, known as Service-Oriented Architecture (SOA), is generally implemented around Web Services protocols such as SOAP and REST and data representation schemas such as with the Extensible Markup Language (XML)

Working our way down to the network layers, the reality of diverse buildings and facilities means there may not be a single physical networking technology that works best across the board. The ability to combine heterogeneous wired or wireless physical communication media is an asset to be leveraged even within a single facility, for example when different departments or different equipment types are best served by different media types.

The Internet Protocol (IP) architecture is widely recognized as the most versatile, scalable and media-diverse networking architecture. One of IP's key assets is its ability to tie together various communication media, wired and wireless, in a single coherent and easy-to-manage framework, with the ability to transport established legacy in-building control protocols such as Modbus, BACnet and LonWorks. Just as telephone and television have converged with the IP-based data network, the "facilities network" is seen as the next such wave of convergence around IP.

Moving farther down toward the physical communication media (e.g., wiring vs. radio frequency use), new building or re-commissioning scenarios leave a wide range of choices of communication infrastructure if one is willing to incur the cost of wiring. However, in common retrofit situations and in buildings where the patterns of occupancy, tenancy, partitioning and activity change frequently, wireless offers the greatest flexibility and future-proofing against the unknown, as well as the lowest-cost deployment in terms of labor and materials.

The newer breed of low-power, mesh-based, wireless networks (e.g., IEEE 802.15.4) offers unprecedented levels of deployment flexibility that translate directly into the desired levels of "enhanced context for business effectiveness" discussed above. Indeed, ultra-low-power requirements equate to practical autonomy of power through long-lasting battery use or energy harvesting and trickle charging of batteries. This removes one set of shackles – co-location with AC power outlets – from sensor placement. Furthermore, the use of mesh networking techniques, in which each node in the mesh can serve as a relay to propagate the data of neighboring nodes, increases the reach and resiliency of wireless communication beyond the old "line of sight to a base-station" paradigm, adding further to the flexibility in sensor-node placement.

Arch Rock PhyNet Platform

Toward the goal of achieving energy awareness, efficiency and effectiveness in commercial and institutional buildings, Arch Rock offers an ultra-low-power wireless mesh networking platform known as PhyNet, with a comprehensive suite of environmental and power-sensing devices. Based on open industry standards at all layers, including Web Services and IP communication using the IETF 6LoWPAN standard over IEEE 802.15.4 low-power wireless mesh networks, PhyNet combines ease of deployment, remote monitoring, ubiquitous reach even in hard to reach or wire places, and investment protection for energy-focused applications.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]