|

February 2016

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

Optimizing Automated Buildings

While each facility’s energy profile is

different from one to the next, the approach for optimization is

generally the same: efficiency before renewables.

|

Matthew Higgins, Founder & Chief Analyst, CEM, HBDP, LEED AP

(BD+C), MBA

Vibrantcy

|

For

an energy engineer, renewable energy and energy efficiency are

becoming inseparable. With the falling cost of solar photovoltaics (PV)

and wind turbines renewable energy is cost neutral or cost efficient in

many cities across the U.S. This is especially true when comparing

Levelized Cost of Energy (LCOE) metrics of fossil fuels (LCOE

by NREL). Coupled with an increased desire to be carbon-neutral or

consume net-zero energy, efficiency measures are not always the first

choice for capital projects among many domestic building owners. But no

matter the means to save energy, the end-result is nearly the same: to

control energy costs.

To truly control energy costs, facility owners are beginning to

evaluate the cost effectiveness of battery technology and much more

dynamic renewable energy systems such as concentrating solar and

solar-tracking arrays. These systems allow for a higher annual energy

production per square-foot and reasonable paybacks in high energy-cost

jurisdictions. But because these technologies can be difficult to

implement in dense urban areas, energy efficiency must be incorporated

in order to reduce the dependency on renewables.

While each facility’s energy profile is different from one to the next,

the approach for optimization is generally the same: efficiency before

renewables.

(Image obtained from Energy.Sandia.gov)

ENERGY

EFFICIENCY

As energy engineers we strive to create building additions without

increasing operating costs and present efficiency measures with two or

three-fold benefits. First, when tasked with a building expansion

facility owners should always look to engineers to incorporate

renewables during construction, typically easing first-cost to a small

fraction of the overall structure. In doing so sophisticated energy

models can be used to evaluate various combinations of constructions

and building systems, in some cases creating a plan to effectively

eliminate utility costs for the expansion. Energy models should also be

used to evaluate potential renewable energy systems based on localized

climate data in effort to forecast net-consumption and create bankable

predictions for utility costs.

Second, engineering analyses should take care to evaluate secondary

effects of conservation measures, such as those inherent in LED

lighting and central-plant optimization. While LEDs are becoming more

life-cycle cost effective than high output fluorescent lighting systems

(EERE Lighting Report), lighting power reductions

alone often

dominate the conversation. But when considering the overall impact

lighting has on a facility, secondary effects such as decreased cooling

load must also be considered. In some cases heat-loads from lighting

retrofits may decrease by 30-50%, potentially extending the useful life

of chillers, pumps, fans, and cooling-towers used to cool these

buildings. A properly automated facility recognizes these changes in

load and adjusts cooling-system performance.

Energy efficiency through central plant optimization has similar

layered benefits, and through retro-commissioning or continual

commissioning can create layered opportunities for energy efficiency in

an automated building. Small measures such as dynamically increasing a

chilled water set-point based on load or outdoor ambient temperature

may allow chillers to operate at a more efficient part-load, while

reducing pumping and cooling-tower loads, and reducing the need for

simultaneous heating and cooling through zone-reheat.

When evaluating combinations of efficiency measures such as these

before contemplating renewables, these decisions can dramatically

reduce a facility’s overall need for renewables, thus reducing size and

first cost of renewable energy systems. But optimization does not end

by agreeing to implement a PV array after reducing a building’s load.

Positioning arrays and sub-arrays based on peak-usage or facility type

becomes essential; further reducing peak loads and on-peak energy

charges.

FUEL SWITCHING

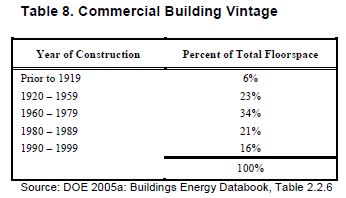

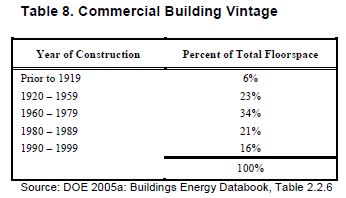

Becoming a net-zero consumer or reaching a benchmarked usage index is a

complex ambition for controlling energy use, one fraught with many

obstacles. Obstacles such as primary heating fuel-type selection,

reliability of historical weather patterns for PV and wind turbines,

and managing process energy consumption from plug-loads. Because the

majority of U.S. building stock is in buildings two decades or older

(IEA Building Stock Report), incremental decisions

to become a

net-zero building (NZEB) are popping up in the existing building sector

as well as in new construction.

When considering fuel-type in a NZEB, offsetting the

cost of natural

gas is commonly compared to the cost of electricity, especially in

heating-intensive climates. This evaluation is often conducted by

engineers electing to use dedicated outside air systems (DOAS) or

energy recovery ventilators (ERV) to de-couple ventilation

air-conditioning from space conditioning systems. This de-coupling

strategy is becoming commonplace among energy efficient facilities, and

is an area of significant R&D. Where natural gas is abundant and

low-cost, factory-installed fuel switching technology may be an

acceptable alternative to DOAS or ERVs with only one fuel source. (Example Systems) Dual-fuel or hybrid systems also

offer the

advantage of potentially benefiting from both PV and lower cost solar

thermal systems, while historically only domestic hot-water systems and

condenser water loops appeared ideal for solar thermal applications.

(Image

obtained from NREL.gov/solar)

Hybrid fuel systems rely heavily on building automation

and allow

facility owners to invest in a more diverse selection of renewables,

allowing solar thermal systems to play a larger role in offsetting

annual consumption. But because of the still limited amount of options

for integration, solar thermal energy is restricted to pre-heating

hot-water systems and alone does not provide a viable path to achieving

net-zero consumption. Unlike converting from electricity to natural gas

to optimize solar thermal collection, net-zero consumption almost begs

the need for an all-electric infrastructure. This decision can be

difficult for facility owners in very hot or very cold climates, where

natural gas may provide an economical benefit from absorption cooling

or gas heating. Where net-zero is a tangible goal and all-electric

infrastructures are possible, energy efficient heat-pump technology can

bridge the gap between a costly electric boilers or reheat systems.

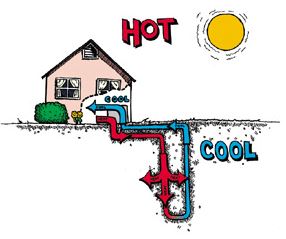

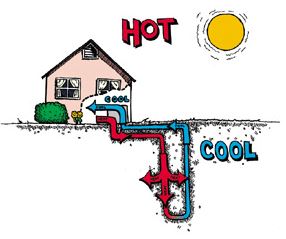

Ground-coupled heat-pumps (GCHP) are sometimes considered renewable

energy systems, as compared to true geothermal systems, and do offer a

renewable source of heat-transfer without the use of boilers and

cooling towers. These two geo systems differ based upon the use of a

distributed array of 250-foot deep bore-holes and a refrigeration cycle

(ground-coupled), versus the use of deeper earth-boring to generate

steam-turbine energy (geothermal). (Ground-Coupled

Assoc.)

While quasi-renewable GCHPs are typically more cost effective than

controlling superheated subterranean temperatures, they tend to be

land-hungry and may eventually require the assistance of a boiler or

cooling-tower. Much like PV and solar thermal, should a facility be

optimized prior to system selection, GCHPs may prove cost comparative

against traditional HVAC systems. In a very limited basis and through

careful automation, GCHPs may also integrate solar thermal collectors,

especially when a bore-field is limited to the amount of heating it can

provide.

(GCHP image

obtained from

IGSHPA.OkState.edu)

NEW CONTROLS

[an error occurred while processing this directive]

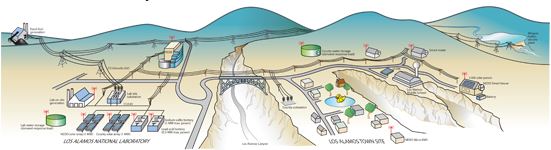

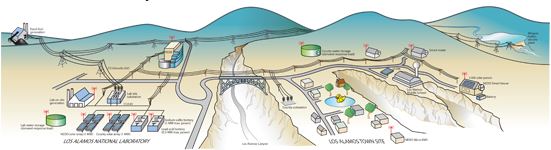

Historically energy efficiency was driven by the attempt to reduce peak

usage and consequent peak demand charges, driving the implementation of

thermal-storage load-shifting. By generating chilled-water or ice

during low-cost off-peak periods, substantial load reductions were

possible when night-time cooling was used during on-peak daytime

cooling periods. While these measures still provide tangible energy

cost savings, new automation technologies such as smart-metering and

grid-scale batteries are beginning to dominate cost efficiency and

reliability discussions. Smart-metering and smart-grid technology allow

for a strategic allocation of low-cost power resources; from power

stored off-peak or renewably generated to be used when charges are

excessive or grids are stressed. While these technologies are often a

result of large-scale institutional research projects (Smart-Grid NM

Labs), smaller micro-grid automation projects offer a

building-wide or campus-wide ability to capitalize on similar

technologies. These “smart” technologies are slowly becoming a third

tier to the one-two of efficiency and renewables.

(Image

obtained from LANL.gov)

IN CLOSING

All this being said, an energy engineer’s analysis and performance

predictions rely heavily upon building automation systems and

responsible building management. Without proper programing, equipment

sequencing, and systems automation an energy master-plan or benchmarked

usage-index is simply not possible. While climate-appropriate renewable

energy systems can be considered as constants in the performance

equation, right-sizing a PV array does no good in a sunny climate when

a facility’s consumption escalates – who is in control then?

ABOUT THE AUTHOR

Matthew Higgins,

Founder & Chief Analyst, CEM, HBDP, LEED AP

(BD+C), MBA

Consulting for energy projects Mr. Higgins has conducted energy

incentives research, energy audits, energy and daylight simulations, he

has sized and planned renewable energy systems, developed site specific

combinations for energy efficient glazing, shading, and construction

assemblies, and assisted with building equipment and control decisions.

Mr. Higgins has worked on over 300 new and existing building energy

modeling projects, over 80 of which had an associated LEED

certification goal. His expertise also includes extensive energy

measurement and verification studies, Energy Star building

certifications, life cycle cost analysis, creation of specialize

analysis tools, and a breadth of public speaking experience throughout

the southwest.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]