|

February 2018

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

How Smart Lighting Headaches Are

Delaying IoT for BAS

The reality is that most

lighting control systems are “set and forget”; after initial setup,

additional interaction is not required.

|

Russ Sharer, Russ Sharer,

Vice President of Global

Marketing and Business

Development

Fulham Co., Inc. |

The Internet of

Things (IoT) offers great promise for building automation. However, in

the rush to address total connectivity, real-world economics tend to

get in the way. While IoT can solve a number of integration and

automation issues, IoT implementation has to overcome market

challenges. This is especially true in the lighting industry, which has

a mature supply and deployment strategy that has been slow to adapt to

new integration solutions such as lighting control, a building block of

IoT. In fact, the luminaires installed today without communications or

sensors won’t likely be IoT capable for the next decade, the lifetime

of the fixture. This delays IoT adoption for lighting at least five to

10 years, which is ironic since building lighting is the perfect

skeleton for IoT.

Lighting as the Skeleton for IoT

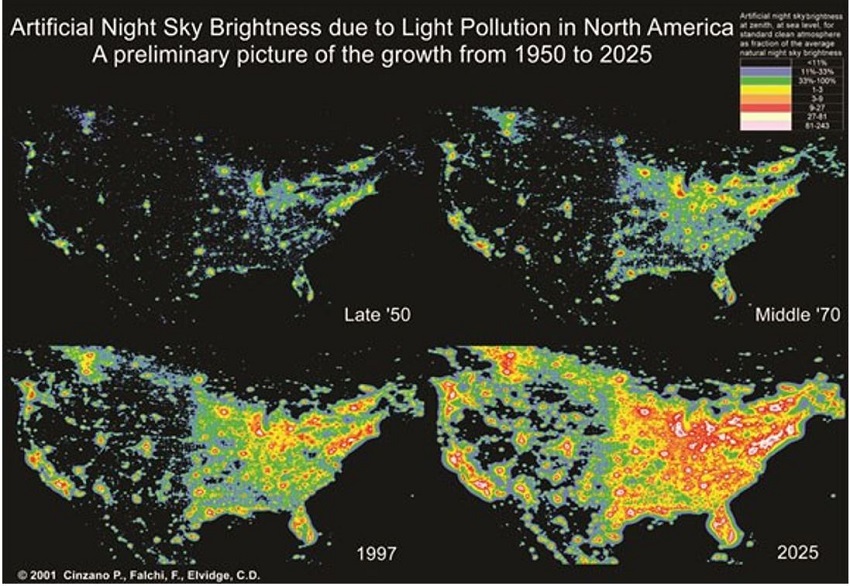

Light is everywhere. In fact, in parts of rural India, lighting is the

first thing families add with electrification. In

North America, light

emissions have grown an average of six percent each year between 1946

and 2000, exceeding the population growth rate. Lighting is clearly

essential to any building.

What

makes lighting the right skeleton for IoT is the fact it is not

only essential, but is installed in known fixed locations at regular

spacing intervals. Building lighting connects to a central, stable

power source. It’s also more ubiquitous than any other part of the

electrical infrastructure, including electrical outlets. When you add

sensors and communications (required for IoT) to light fixtures, they

can have the intelligence to detect smoke, bad air quality, even the

sound of a gunshot, and report back to a central location.

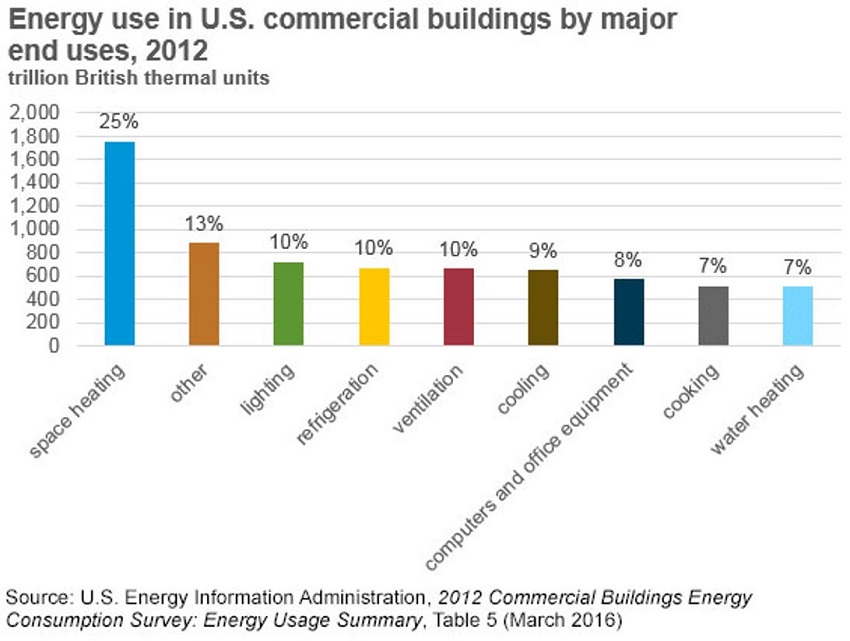

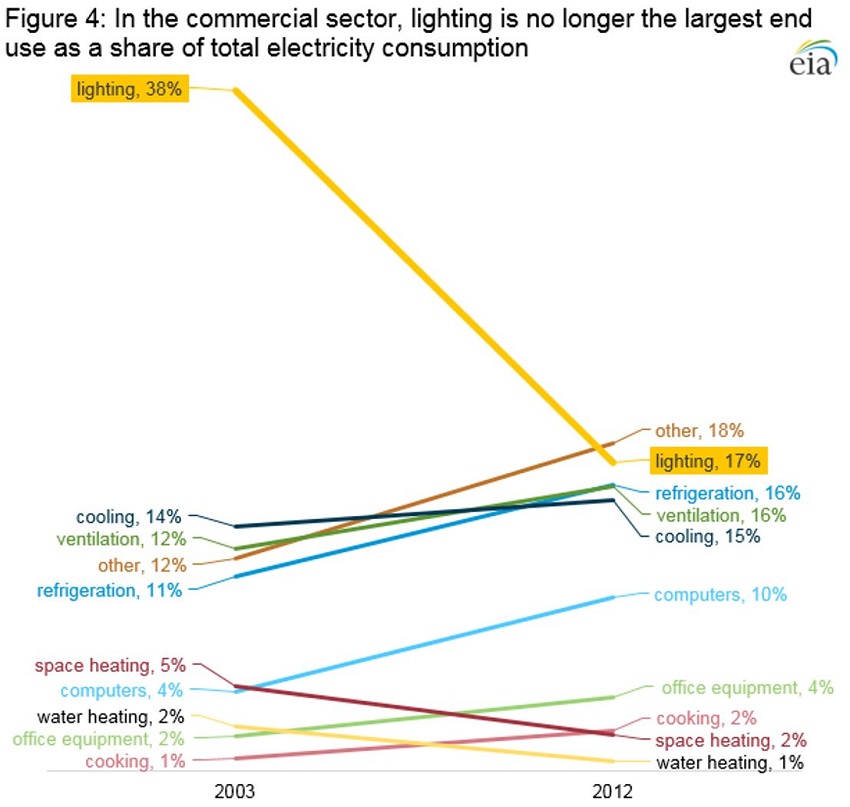

Lighting also can be a driver for BAS adoption since it consumes

substantial energy, which means monitoring and conserving the energy

used for lighting can save a lot of money. According to the U.S. Energy

Information Administration, 17 percent of the energy used in commercial

buildings goes to lighting. Between 2003 and 2012, lighting as a share

of overall electricity consumption dropped from 38 percent to 17

percent, largely because of more efficient lighting such as LEDs.

Much

of the LED deployment in the United States has been driven by

rebates from energy companies and cash incentives yielding an immediate

(less than 24 month) payback. What’s more, simply swapping out legacy

lighting for LEDs yields 80 to 90 percent of the energy savings, so

there is no real incentive for adding more savings by including

lighting controls in BAS systems.

However, there is inherent value in connected lighting, especially if

you are looking to adopt IoT. The ubiquitous nature of lighting makes

it the perfect skeleton for IoT. Just as networking companies like

Novell and Hewlett Packard started by connecting PCs, printers, and

file servers, lighting can be a great starting point for IoT

intelligence.

Why Lighting is Holding Back IoT

Unfortunately, having lighting as a ready-made framework for IoT is not

enough. There are too many market and business impediments in the way:

- The distribution channel –

Lighting always has

been part of building construction, and light fixtures make their way

into installations through distributors and contractors, chosen for

lowest cost and ease of installation. If a contractor can come in and

wire the lights quickly, without complexity, the job is less expensive

and the customer is happy. If a contractor has to meet deadlines and

improve profitability on a job, they want to minimize complexity, which

includes taking the time to wire lighting controls into the building

infrastructure.

- Capital expenditures

– How lighting costs are

included in the construction process is another impediment. Lights are

installed as part of the initial construction, so unless the building

owner or tenant is thinking about smart lighting as part of building

automation from the outset, lighting will be specified as a line item

along with the nails and the dry wall. Similarly, tenants tend to

choose lighting based on aesthetics and light intensity, but not on

manageability.

- Rental agreements –

The structure of rental

agreements often calls for tenants to pay for the energy they use. That

means there is no incentive for building owners to pay for an

infrastructure to manage energy consumption. In fact, many commercial

properties don’t even monitor energy use by office or floor, so it

would be impractical to try to reward tenants using lighting upgrades.

- Outdoor lighting –

Just as landlords have little

motivation to install more energy-efficient lighting, there is no

incentive to upgrade and monitor outdoor lighting. Many utilities

charge municipalities by the light pole rather than for actual energy

usage.

- Less commercial construction

– New construction

offers the best hope for IoT-managed lighting, but half of the

commercial space in use in North America is at least 60 years old.

Since 2000, only 7-8 percent of new commercial capacity has been added

per year. Researchers predict that more than half of LED lighting sales

through 2025 will be for building retrofits. So even if all new

building starting wiring for IoT, it would still take half a century

for approximately half of all commercial space to be IoT-ready.

As

you can see, there are a number of market barriers preventing IoT

deployment through smart lighting. Perhaps the biggest is that

retrofitting with LED lighting are a huge energy savings in itself. If

you consider that fluorescent lighting consumes 2 percent of the

world’s energy, and LED retrofits will reduce the power needed for

lighting by as much as 90 percent, most economic incentives can be

achieved with conversion to LEDs.

The Real Issues of Lighting

Management

Historically, building lighting has been installed by the contractor

and when it stops working, you called an electrician. With IoT

controls, lighting becomes part of a more sophisticated infrastructure

that takes more expertise to maintain. If a control system isn’t

working who has responsibility for repairs? If there is a problem with

a wireless connection or controller, is that a problem for IT? Most

facilities managers and IT professionals don’t have the expertise to

include lighting control systems and IoT in their wheelhouse.

In many cases, a system failure would have to be handled by the

manufacturer. Unfortunately, the manufacturer has no direct

relationship with the end user, or even the crew sent to repair the

system. Some vendors are creating training centers for contractors and

installers to address this problem but there is still a gap when it

comes to certification and repairs.

The reality is that most lighting control systems are “set and forget”;

after initial setup, additional interaction is not required. The

lighting control systems either work or they become a problem and are

disabled. In fact, research shows that half of all U.S. lighting

control systems are disabled after 12 months because of unresolved

issues.

Time to Rethink How to Sell

Lighting Control

To help IoT become an accepted platform for smart lighting as part of

building automation, vendors should consider a new approach to selling

and supporting lighting controls.

First, listen to end users and determine how best to incorporate

lighting controls into ROI scenarios. For example, lighting controls

can offer tremendous energy savings when tied to other systems, such as

HVAC. This is a major opportunity for BAS vendors with integrated

lighting control, increasing the return with minimal additional

investment. It would be similar to selling email as part of a

network system; it’s a great value-added service but harder to sell as

a standalone solution. Incorporating lighting controls as part of a

security system, fire and safety, environmental controls, or other

building automation system makes more economic sense for building

managers.

Other ways to think about lighting controls is as part of another

solution, such as item tracking. For example, hospitals tend to buy

more equipment than they need to increase availability; what if the

lighting system could help track the location of all the equipment in

the building?

For IoT to become successful for lighting controls, vendors need to

improve and simplify both the ROI and the installation. As smart

buildings become the goal, it will be easier to make lighting controls

part of the overall infrastructure, opening the door for IoT.

_____________________________________

About

Fulham Co., Inc.

Fulham

manufacturers innovative and energy-efficient lighting sub-systems and

components for lighting manufacturers worldwide.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]

Russ Sharer,

Russ Sharer,