|

June 2016

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

Data Driven Building Management

The

real secret to success with this data was how we used it. We enabled

teams to engage with one another towards a common goal and get more

done.

|

Jason

Burt

VP Product

Buildpulse

|

Before

starting an analytics company for buildings I lived another life in

the startup world. I had worked in many roles developer, analyst, and

product manager for companies that analyzed data to make operational

improvements and recommendations for companies. We analyzed the

operational logs from companies such as Google, Microsoft, and Walmart

telling them how to improve their sites and increase customer

engagement.

In many ways that space is the future of where analytics in buildings

can be. But though we could measure and analyze anything from what

people clicked on to what they searched for the real secret to success

with this data was how we used it. We enabled teams to engage with one

another towards a common goal and get more done.

What Automation and Software Will

do to the Industry (no robots will not take over)

While I write this article we have processes that are

automatically discovering data in Building Automation Systems. Once

identified the data is automatically standardized to a tagging schema

based on Haystack and ASHRAE standards. This automated process allows a

few people to connect hundreds of buildings a month to a modern

analytics service.

People’s first reaction to this is to worry about robots replacing

them. It makes sense because they often think their value add is

aligning data or shifting through a few controls to find ‘unique’

issues even though the issues in buildings are not new or unique. PNNL,

ASHRAE and many others have documented these.

But what people are missing is that automation unlocks their time.

Facility managers who want the most bang for their buck can focus teams

on specific issues without having to dig through raw data. The GSA, who

recently presented at NFMT’s High-Performance Buildings conference,

estimated that data driven approach to facility management not only

saved them 8-10% in energy but also recovered .20 -.30 a sqft in

operations and management. One customer with 90 buildings had two full

time techs digging through data to look at systems. Over the course of

a year they verified operations in 40 of those buildings. An automated

process can verify operations in all 90 buildings every 5 minutes.

Freeing up that team to fix issues that appear.

Building Better Relationships Using

Data

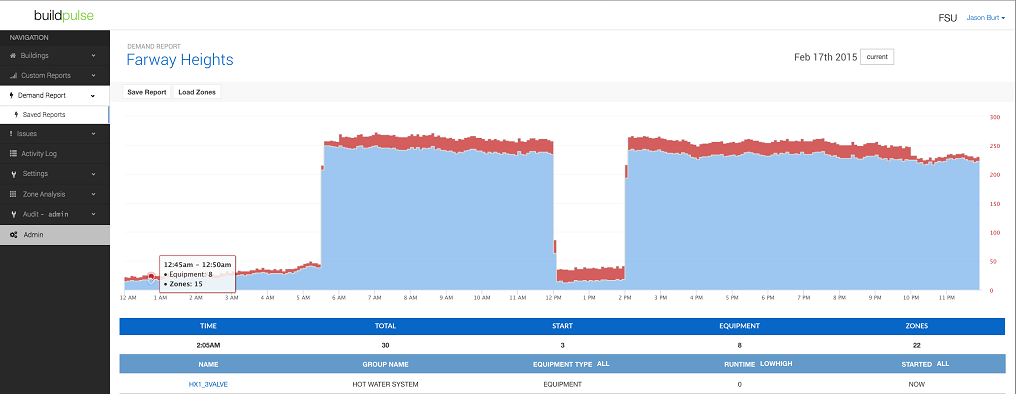

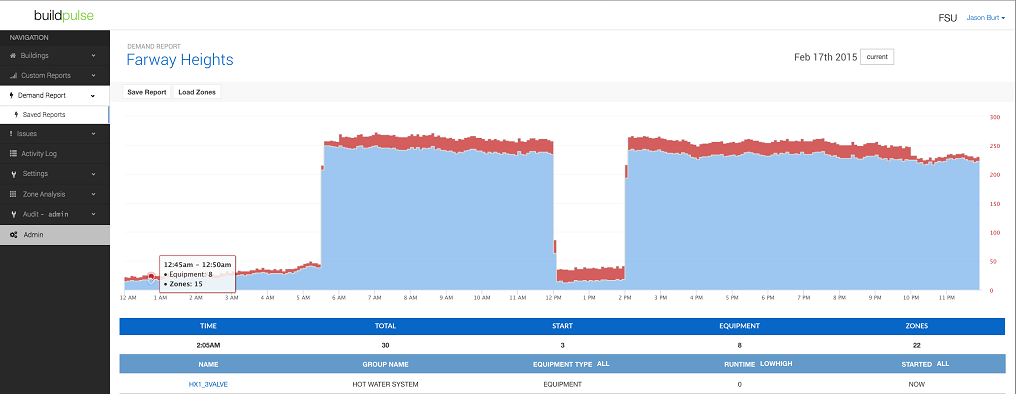

Modern analytics tools are a feedback loop that help

more than just facility teams. Commissioning agents and controls

contractors that once spent days trying to align data and setup basic

trends are now spending that time working with their customers on

fixing issues in their buildings. They have targeted reports that show

areas that schedules, set points, and sequences can be adjusted. They

are creating value add services, no longer spending their valuable time

just making sure the database is online or the data is correct.

Continuous monitoring has allowed them to make the transition from

transactional to relational services. They are able to discover things

such as issues that occur outside of occupied hours that are often not

caught. For example weekend sequences that the Monday through Friday

team would never catch.

The service providers use automated analytics as a diving off place for

customer engagement. They check up on the low hanging issues that

require no capital expense to follow up with larger improvements that

fall into capital management.

Choose Your Key Performance

Indicators

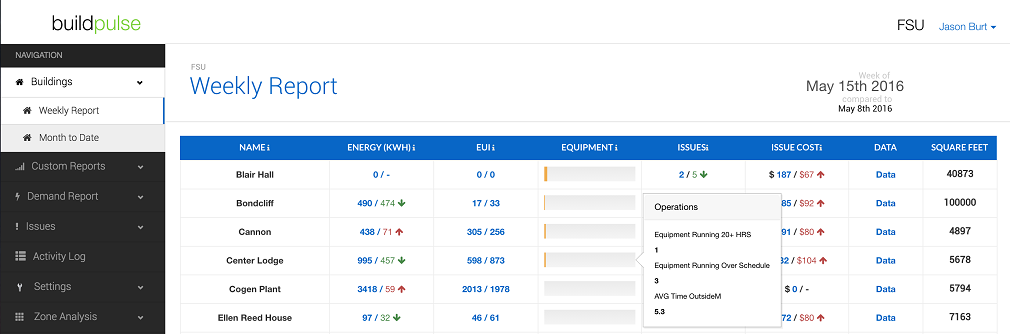

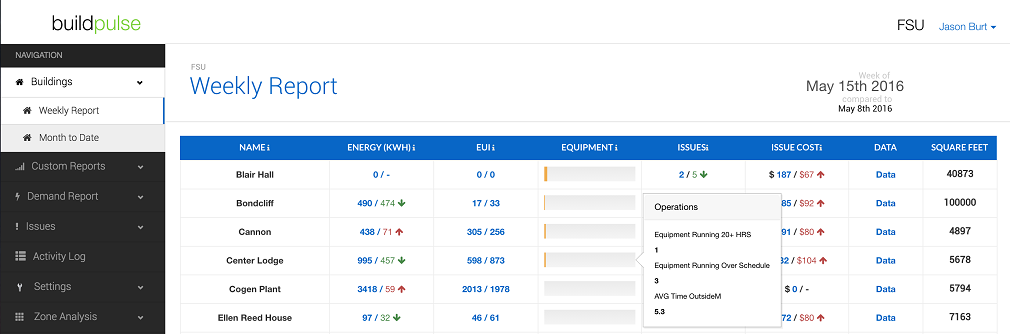

If you're bringing data and analytics into an

organization it is good to start with a conversation around goals.

Improving operations while maintaining comfort for tenants is

achievable but it requires visibility into both. Once these are

established matching the goals to KPIs (Key Performance Indicators)

will give you a guide to where you should gather data. We normally look

at comfort along with energy savings which we break into equipment

runtime and performance.

Your KPI’s should show you areas for improvement. They are not

dashboards that show graphs that are disconnected from the underlying issues. While

energy and EUI are good starting points, they can lead to a false sense

of completeness. We had one customer who had done a great job of

improving performance in their buildings. They had a number of

buildings with 90s in energy star ratings, after we installed there

were still roughly 10% savings in those buildings. All low hanging

fruit.

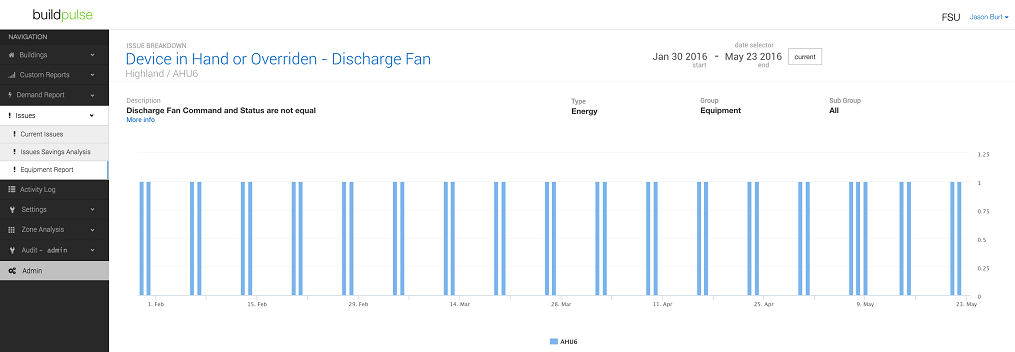

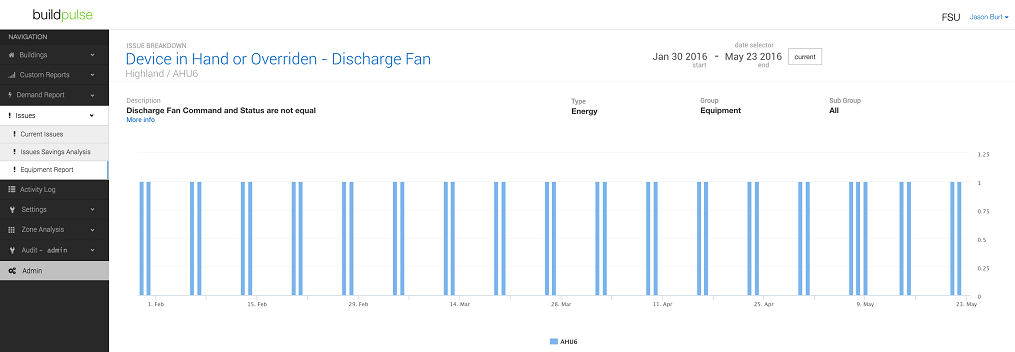

Below is a common occurrence, equipment running 24/7 so if you were to

attempt regression analysis on the kwh data you would miss it.

IOT is Short for a Lot More Data and More Systems to Maintain

[an error occurred while processing this directive]The sheer amount of data and information coming from

systems can be daunting. A 100,000 sqft building can have tens of

thousands of data points. Summed over a portfolio of buildings keeping

track of and maintaining that data can be daunting.

In addition, more affordable hardware is enabling more of the building

stock to come onto the market increasing the amount of data to shift

through. Where once controls made economic sense in larger buildings

smaller buildings are becoming more available.

While the number of sensors and controls being installed is increasing

the size of most facility teams is not. To successfully mange these

additional systems a clear plan needs to be in place. Sensors should be

prioritized based on the impact they have on systems and a monitoring

plan should be set to automatically check these sensors for variances

or issues. For example the impact of an Outdoor Temperature sensor can

be significant compared to an individual thermostat. Having an

analytics service take care of monitoring and prioritization allows

teams to increase time between manual service while reducing the impact

of faulty sensors.

Analytics With a Purpose

There are large opportunities to leverage data and

analytics in building operations, but to be successful one has to

remember what automation and analytics are for. Modern analytics

services should reduce the amount of time teams spend looking for

issues or verifying things are running within expected bounds. They

should help teams improve their workflow and provide assistance in

prioritizing issues.

Cause at the end of the day it’s the team that makes the impact.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]