|

June 2017

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

Filling the BeMS Training Gap

Companies

who truly understand the systems they have installed and their

relationships are able to make best of use their Building energy

Management System and help them achieve their objectives of saving

energy and reducing carbon emissions.

|

Steve

Harrison

Technical Director

Optimised

Learning

|

The

old saying “rubbish in means rubbish out” is probably relevant today

more than ever.

Generally, most Building energy Management

System operators are aware that they have intelligent building controls

installed on their heating and ventilation equipment, and there will be

a good level of knowledge to manage this.

But what operators often don’t appreciate

is the huge benefit controls can bring to reduce the long-term running

costs of their building with very little capital expenditure.

Using what we already have in place, and

understanding the relationship between devices sometimes operating

independently in the same system means we can ensure there is good

“Relational Control” between different manufacturers products. Users

who deploy this strategy will be seeing an immediate impact on energy

reduction and higher long-term energy saving.

First, what are the rewards?

To understand this better, we need to go

back to some basic facts. There is a growing realisation that most of

the costs regarding the life cycle of a commercial building are running

and maintaining it. In fact, over the whole lifecycle of the building,

the figures are approximately 25% for the design and construction of

the building and 75% for the operation and maintenance.

Let’s take the initial design and

construction, of this just ten per cent of the entire lifetime costs of

a building are made up of its construction. And yet, it is here in this

small margin that contractors attempt to squeeze budgets hardest. This

leads to control systems that are either incompatible or will not

communicate with the Building energy Management System. That means even

at hand over the building may not have a cohesive energy management

strategy.

Of the remaining 75%, it is safe to say

that much of the costs are related to building services – heating,

ventilating, air conditioning, and lighting. It is only through good

building controls that these costs can be managed effectively. By

understanding the relationship between incompatible systems, the

Facility Manager can directly influence the performance of a company’s

profit and loss. This is not only by saving energy in the building but

also because of the relationship the built environment has to

productivity.

One of the most efficient ways to improve

the quality of the environment we work in is by understanding how we

control it. To do this, we need to understand “Relational Control.”

How to understand “Relational

Control” in Building Services

The rise in demand for controls and

intelligent equipment presents the building services industry with a

massive integration challenge; to maximise the value from today’s

controls, systems must communicate with each other effectively.

The controls sector is going through a

change right now, and a shift toward the efficiency of factory fitted

controls with “open” protocols and multi-vendor networks. This means

there is growing pressure on end users to understand the minefield of

communication compatibility. This is not straight forward even for

“compatible systems,” but the rewards of integration are huge.

Open protocols can seem confusing, but

operators need to be aware of the main contenders such as BACnet,

LonWorks, Modbus, and KNX. Using open protocols makes it much easier to

build up a relationship between smart equipment, and the BeMS.

A recognised and approved controls company

can very quickly ascertain if you have good “Relational Control,” or

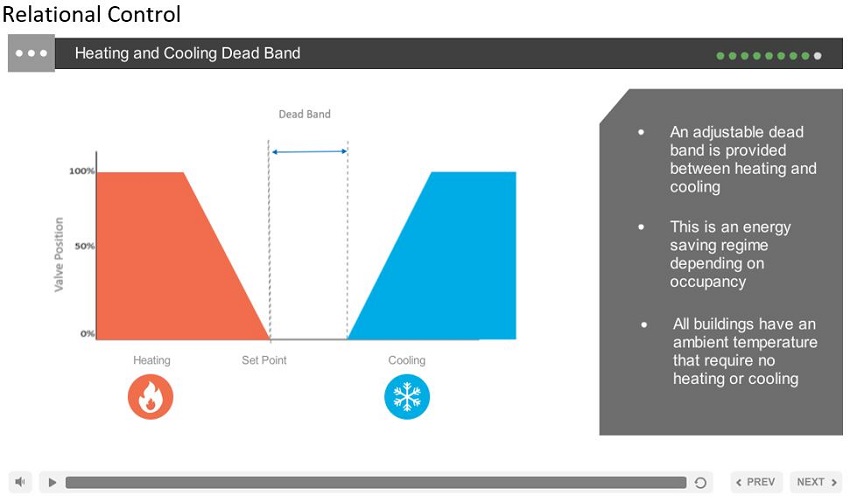

two systems competing against each other. In its simplest terms, one

system could be in free cooling mode bringing in cold air from outside,

whilst another system is calling for heat. If we build a relationship

between systems, there is less chance of this happening. This is what

we call “Relational Control.”

What are the latest BeMS

innovations to enable Relational Control?

Building controls are technically a

fast-moving sector, and manufacturers are investing in new technologies

all the time. We are now seeing more cloud-based data storage; this is

an enabler to “Relational Control.”

The data is normalised and held centrally;

this means the capability of front-end software of BeMS is also

developing, bespoke dashboards allow us to build user interfaces that

help us create an efficient energy strategy. It also means end-users

can access information on building performance from different systems

and assemble it in one place.

The emergence of factory fitted controls,

smart pumps, fans, chillers and even sensors with cloud access means

that better basic understanding of this technology by end users is

needed, this will help them to specify holistic systems and identify

what is available now and in the future.

Looming Legislation!

Energy Savings Opportunities Scheme should

encourage companies to take note of what they can do to save money;

this should lead to more awareness about how cost effective building

controls are when it comes to saving energy.

The more significant step forward for the

controls industry was the recognition in the new Part L 2013 Compliance

Guide of BS EN15232 which offers a methodology for grading Building

energy Management Systems.

It is a good time for large commercial

property managers to review their building stock to see how “Relational

Control” can be improved. Thanks to BS EN 15232, the math’s can now be

easily done to highlight inefficiency.

From April 2018, a new legal standard for

minimum energy efficiency will apply to rented commercial buildings.

This means that it will be unlawful to let commercial buildings with an

energy performance rating of F or G.

Large commercial property managers are

already reviewing their building stock to see how energy performance

can be improved – and effective building controls and building controls

training can play an important part in that process.

Optimised Learning means Optimised

Buildings

The controls industry has always prided

itself on raising standards and professionalism, manufacturers of

control systems supply end user training on their own brand of Building

energy Management System. This is manufacturer specific and is

completely fit for purpose.

[an error occurred while processing this directive]But as discussed earlier, buildings are

often delivered with many different manufacturers controls that need a

good “Relational Control” strategy.

This is simply explained in plain English

by Optimised Learning’s eLearning modules on ‘Understanding BeMS’,

these modules cover many of the roadblocks discussed in this article

and give End Users and Facility Managers a much better understanding of

a holistic energy strategy.

There are four basic courses; the first is

an outline of a BeMS, the second covers cooling, the third, heating and

finally air conditioning. All are at a basic level that allows the

student to gather some of the vernacular used by controls engineers and

gives real tips and hints on how to save energy. There is also an end

test, a multiple-choice questionnaire to ensure the message has been

delivered.

Companies who truly understand the systems

they have installed and their relationships are able to make best of

use their Building energy Management System and help them achieve their

objectives of saving energy and reducing carbon emissions.

About

the Author

Steve Harrison, Immediate Past President of the Building

Control Industry Association has been 28 years in the control industry

and is the Technical Director of Optimised Learning.

https://www.optimisedlearning.com/bems-1

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]