Lessons learned from running an innovation project from the home office.

https://www.linkedin.com/in/nicolaswaern/

https://twitter.com/BuildWhispererContributing Editor

|

March 2022 |

[an error occurred while processing this directive] |

| Remote is dead. Long live remote. Lessons learned from running an innovation project from the home office. |

https://www.linkedin.com/in/nicolaswaern/ https://twitter.com/BuildWhispererContributing Editor |

[an error occurred while processing this directive]

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Links |

| Software |

| [an error occurred while processing this directive] |

My company WINNIIO

won this innovation tender a year ago where a municipality

wanted someone to create something that didn’t necessarily exist yet. The

intent was to reduce the CO2 footprint for three schools with an innovative

product for radiator control.

The project

was supposed to start at the end of January, but started in Late April. We were

already late coming out the gates. And we were supposed to come up with a new

product before the summer so that we could ship it to the three schools and

install it before the winter season started.

This of

course didn’t happen. I’ll spare you of some of the earlier the details and

focus more on the lessons learned. This was a completely new product that was

put together with pieces from different parts of the world with teams dispersed

on 3 continents.

“Get

out there on site and work from room to room to room, to get everything done

with remote teams working alongside people in the building. Not in 30 minutes

per day, make sure to get the whole system up and running directly. Take the

time.“

-

WINNIIO

as the solution provider.

-

Customer,

real estate owner

-

Founder

of an IoT company with an open source IoT-tool kit, 20 patents in smart grid

areas

(Based in California)

-

3rd

party Intelligent District Heating platform

-

OEM

of actuators for radiators

-

Energy

advisor

-

Users

of the schools (principal mainly)

-

Local

fibre optics company

This was

during peak Covid, so we did not have that much choice but to start off with

remote ways of working. I did not really see this as a problem, and we met in

teams once a week but of course worked in between the meetings. This was not

that much of a problem in the early stages of the project, but all the lag time

between stakeholders was building up to a problem at the end.

-

We

vetted about 4 different wireless/IoT options and were about to go with one of

them. But a person close to the project had said that this specific project was

a pain to work with so that was disqualified based on those reasons. Good or

bad, but it’s never good to start in an up-hill battle.

-

Since

I am a big Digital Twin fan, we turned the drawings into 3D models

-

We

then chose the actuator model based on the actuators that was already on the

radiators

-

We

chose the wireless mesh stack because of its edge capabilities. I personally

knew the founder from before and having installed the tech in data centers.

-

We

sent the actuators to the US to create a new product from scratch

-

The

actuators were BACnet/Modbus compliant and originally designed for larger

valves, not radiator valves. But this was an innovation project, so we used

them for its ability to troubleshoot more granularly than what was common.

-

The

founder of the IoT company went out of his way to design a new product, find

housings, and test this at their test bench with a couple of samples.

-

We

made it work and had to source everything during peak Covid and get it

delivered to the smallest school to try it out

-

Meanwhile

the developer who was supposed to work on getting to know the stack during

summer couldn’t get it done so we were also behind on that front

(in all fairness, it was an impossible task for one person to do, and at a

junior level)

-

After

a lot of back and forth, with multiple trips to FEDEX to coordinate things

between the OEM and California we had a prototype.

-

We installed the prototype at

the smallest school and if this worked, we were going to scale

-

it

up and out to the two other schools, starting with the largest first.

-

We

had just started with a new dev team, with a new stack, modified to work with

NODE-Red, with a new project, completely distributed. It was a recipe for…

success, but with a lot of pitfalls.

-

The

head developer assured that everything looked great and we could start rolling

it out

-

We

got the sensors, the new smart hub, the whole IoT-solution 3 days before

installing it

-

The

end customer hired local installers who installed everything based on

installation instructions that were far from stellar

-

We

didn’t test the system when they were there because I thought it would just be

plug and play (it wasn’t).

So far so

good. But when everything was installed, it proved to be a challenge to correct

small problems in the building.

-

The

customer did not have dedicated people to work with us on this, so they had to

take time from people who had regular day jobs, albeit focusing on technical

asset management and IT related areas

-

New

stack, new developers, new everything lead to a lot of small problems

-

We

thought we had everything up and running from the first small school, but we

did not

-

The

instructions on how to pair the actuators with the radiators to the correct

Modbus ID was everything but simple

-

The

instructions from the OEM on how to pair it was lacking information and we had

paired everything with wrong ID’s. Which meant that we couldn’t control the

radiators

-

Innovation

- Everything was shipped directly from factory which meant that some of the

products were not working correctly (5%).

-

Working

with wireless Modbus was great in theory, but for a dev-team that has never

worked with Modbus, it was challenging at first to get an understanding of what

needed to be done

-

And

the only reason the developers needed to know about Modbus was because the IDs

of the radiators weren’t configured correctly so we spend weeks thinking it was

a software issue (we looked for errors in all the wrong places)

-

Wiring

was not necessarily correct at all times

-

Batteries

that were supposed to be infallible were in fact not working all the time

-

API

integration was easy from one side, but because other 3rd parties

were not using standardized frameworks of integration that side took a lot

longer than necessary

Everything

is of course easier in hindsight. We have learned a lot. The most valuable

lesson would be to get out there on site and work from room to room to room, to

get everything done with remote teams working alongside people in the building.

ALL the major stakeholders need to be there at the same time. Not in 30-minute

intervals. Make sure to get the whole system up and running directly. Take the

time.

à

More on that here:

Digital Twins and the Metaverse

The thing

is that if you can take 20 hours each from 10 core people that equates to 200

hours, over three days of install and testing. Do it.

The

alternative could be 1 hour each from 10 people in a series of events,

totalling 400 hours over the span of months. This is not covering actual

software development work, but to get to that point where all the data is

flowing.

-

Have

a communication plan to get the right information out to the right stakeholders

-

Put

the right people, with the right tools, and the right information together as

fast as possible and work together

-

Take

meetings, and only use emails for information about decisions being made in

meetings

-

If

you know what you should do, don’t wait to do it

-

Time

is everything. Get it installed, and working, whatever it takes.

-

Get

out there on site and work from room to room to room, to get everything done

-

of

wasting time checking too much, exchange it for a new one that works and figure

out why it’s not working afterwards

-

Ockham’s

razor strategy in testing everything, and testing fast, which infers simple and

direct explanations first.

-

Continuous

communication and do not over-sell the project early on. Especially if it’s an

innovation project.

-

One

throat to choak. Take care of the install and minimize the amount of hands-on

deck as much as possible.

-

Open

is not necessarily amazing if it’s not interoperable.

-

The

customer wants stuff that works. No one cares about taxonomies, ontologies, AI,

machine learning, wireless mesh etc etc.

3-2-1…. Conclusion

3-2-1…. ConclusionInnovation

is not easy. Especially not during a pandemic.

But it’s

worth it. Being out on site. And telling a developer on the other side of the

world to send a command to open the valve of a radiator in front of you.

Through wireless Modbus.

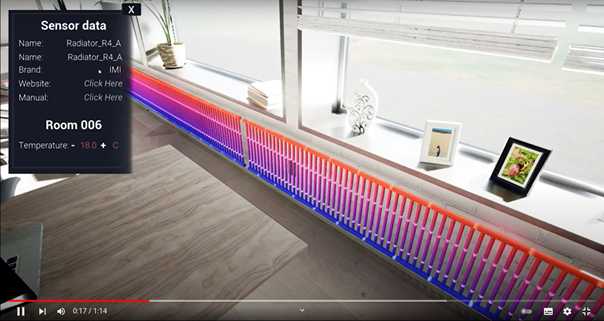

And for

them to count down from 3…2…1… open valve! And to see the orange light turn on

at the same second on the actuator. And to feel the heat of warm water flowing

into the radiator.

That is as

hot as it can be.

It has not

been easy. But it has been worth it. We are now able to control 100s of

radiators in real-time to open close, check return temperature. And for the

context of CO2 sensoring, motion detection, windows open and closed,

temperature/humidity to tell us what to do and when.

The

benefits across the 3/30/300 are immense. And together with self-learning

aspects and a digital twin approach, I think this will be something interesting

for the owner to work with.

Being able

to do things remote at any given point in time is a prerequisite for successful

solutions today. But it’s important not to lose sight of the work that has to

be done in the real world. Physical presence was a key factor here, and it’s a

combination of remote teams, working with boots on the ground that will be a

winning combination. Most likely, assisted with modern tools, used in just the

right order.

If you want

to know what the future will do in a week, a month, a year from now? Subscribe

to Beyond Buildings and find out. And if you want to create the future before

everyone else? Reach out to me and we’ll make it happen!

Sincerely,

Nicolas

Waern

CEO & Founder at WINNIIO Consulting

Nicolas Waern is the CEO, Strategy &

Innovation Leader, and a Digital Twin Implementation Specialist at the

consulting firm WINNIIO. He is a firm believer that the

Real Estate Industry needs more of a lifecycle focus where we need to go Beyond

Buildings and come back with an understanding what tools and technology we

could use. And to solve the jobs to be done, together, with an open mindset.

Nicolas is

working with leaders in several industries to understand how they can succeed

in the age of AI. Predicting what the world will do in a week, a month, a year

from now and to best utilize strategies and solutions that pass the test of

time. He does this through a Digitalization- on Demand approach for anyone that

needs to change before they have to.

Nicolas is also a Podcast Creator & Newsletter Editor for Beyond Buildings

Thought Leader regarding Smart Buildings & Building Automation for AutomatedBuildings

Speaker and Influencer Event Streaming Platforms as the Holy Grail for

Industry 4.0 Applications

Subject Matter Expert Real Estate Digitalization Proptech Digitalization Expert

Active Member of Digital Twin working groups Digital Twin Subject Matter Expert

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]