May 2004

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

May 2004 |

[an error occurred while processing this directive] |

|

This is second of 9 articles on VBHQ where we introduce the building, the cost benefit for interoperability and the cost benefit gained from the procurement technique achievable with open systems and choice. April's introductory article Cost Comparison Model Open vs Proprietary |

Paul D.J. Mason, C.E.O. |

VBHQ,

virtual building head quarters, is a complete building design. The purpose of

the building is to compare the costs of different systems. The first cost

comparison is traditional conventional controls compared to an integrated

solution using the LonMark System.

VBHQ,

virtual building head quarters, is a complete building design. The purpose of

the building is to compare the costs of different systems. The first cost

comparison is traditional conventional controls compared to an integrated

solution using the LonMark System.

The building is a rectangular building with a central core 10m from the edge three sides and 16m on the fourth side; the building provides a classic 80:20 net to gross on its floor area. There are 8 floors of office and headquarter facilities; the building has plant on the roof and in the basement.

|

[an error occurred while processing this directive] |

The cost comparison for this first scenario was carried out by Turner and Townsend Group (http://www.turnerandtownsend.com). T & T created a research and development project so as to guarantee their independence; the hypothesis was that an integrated building based on the benefit of the LonMark System and its certified interoperability would cost less in capital expenditure than the traditional conventional approach. The summary cost comparison table was published last month and is repeated here.

|

Virtual Building Head Quarters 118,402 sq ft2 |

Conventional Installation |

Cost per foot˛ net |

|

Open System Installation |

Cost per foot˛ net |

|

Shell & Core and Category A, Basic Works: |

$ |

$ |

|

$ |

$ |

|

The M&E works, Cat A |

7,198,400 |

60.80 |

6,668,800 |

56.32 |

|

|

Testing and Commissioning, Preliminaries, BWIC |

1,169,600 |

9.88 |

1,064,000 |

8.99 |

|

|

Lifts And Conveyors |

1,152,000 |

9.73 |

1,152,000 |

9.73 |

|

|

Shell & Core and CATEGORY A Works Total |

9,520,000 |

80.40 |

|

8,884,800 |

75.04 |

|

Capital Saving "CAT A", no LON integration works |

6.67% |

635,200 |

5.36 |

||

|

Category B, Fit Out Works |

|

|

|

|

|

|

The M&E works, Cat B |

2,702,400 |

22.82 |

|

2,632,000 |

22.23 |

|

Testing and Commissioning, Preliminaries, BWIC |

440,000 |

3.72 |

|

428,800 |

3.62 |

|

CATEGORY B Works Total |

3,142,400 |

26.54 |

|

3,060,800 |

25.85 |

|

Network Integrator |

0 |

0 |

200,000 |

1.69 |

|

|

External Services |

180,800 |

1.53 |

180,800 |

1.53 |

|

|

CATEGORY A and B Works Grand Total |

12,843,200 |

108.47 |

|

12,326,400 |

104.11 |

|

Capital Saving "CAT A" and "CAT B" |

|

4.02% |

516,800 |

4.36 |

|

This cost comparison table is converted from standard prices in London, U.K. and converted to US dollars at the average exchange rate of 1.6 USD to 1.0 GBP. The rate for square feet is converted from meters net. As can be seen this analysis has produced a good half million dollars US of capital cost saving.

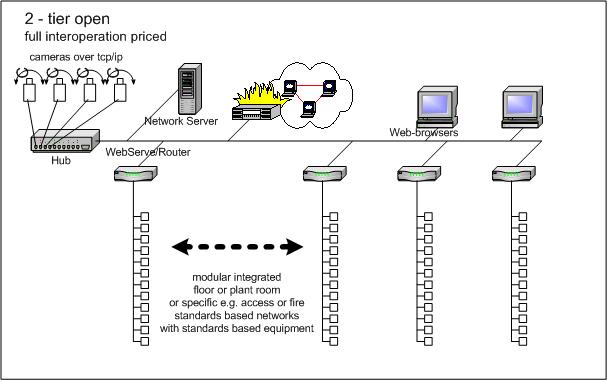

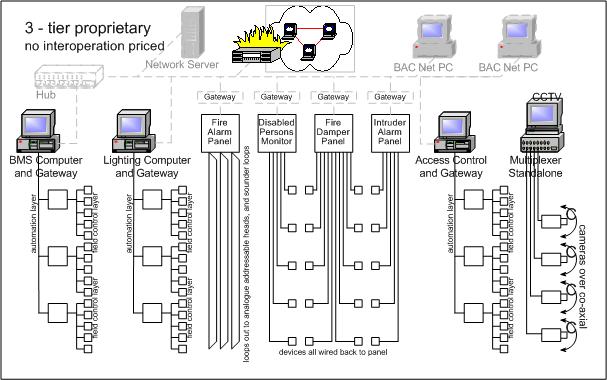

This cost comparison must be further understood, I will explain the key points to note next month, however for now I shall introduce you to the VBHQ. The comparison was deliberately managed in a very conservative manner to be fair to the conventional traditional method. The integration of the LonMark System products is taken for granted and is a real benefit. No integration was priced for the conventional traditional solution. The gateways and the integration BACnet infrastructure and the BACnet supervisors are all not included in the pricing comparison; for full apples versus apples one can see even further savings will be available. The following diagrams demonstrate the two schemes, the conventional installation 3-tier proprietary compares to 2-tier open as depicted by these pictures.

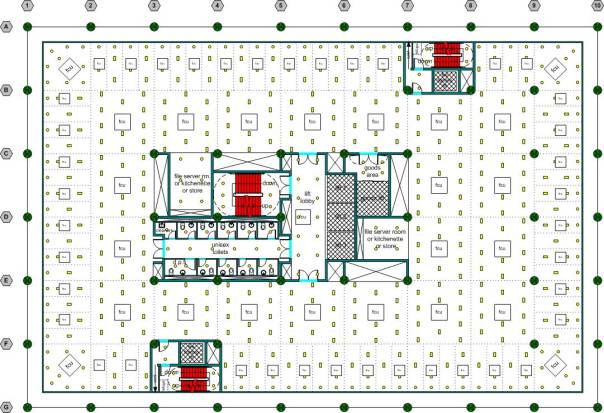

A couple of shots of the drawings of the building follow to give you an idea of the scheme.

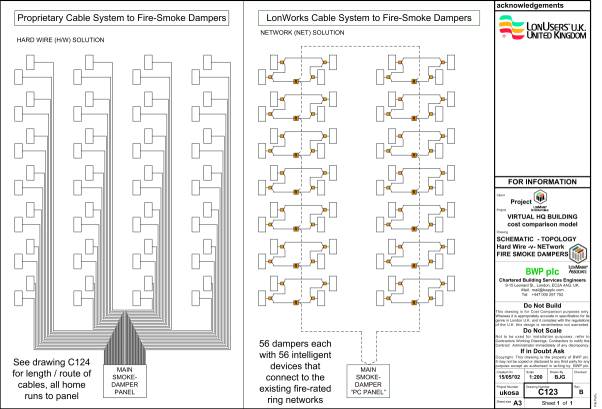

In order to price the building a sufficient series of drawings for each of the systems were produced. An example of the benefit of network cabling is the fire damper system, see the following drawing. This saves 0.75 miles of fire rated cable (or 1.2km) and the carcassing and installation of the cable.

Intelligent building is reputedly more expensive. The proposal here is that by design and by an intelligent procurement technique the automation element of an intelligent integrated building has less capital cost than a similar disintegrated traditional conventional installation.

4% less on the whole building services "standard" budget is a serious number and worth achieving. This saving is achieved using standard "commodity" products that are all interoperable and thereby facilitate integration. Interoperability is the key issue, international standards, common agreement by the widest possible industry trade association and quality certification are completely necessary for good interoperability. The ability to choose different manufacturers products each with similar performance is part of the story. The interoperability is the essence of the cost saving.

[an error occurred while processing this directive]The procurement technique needs some explaining as it is an important part of the savings. In order to understand the saving it is necessary to understand the procurement models of the 3-tier and the 2 tier-options.

"3-tier" The BACnet model and the traditional proprietary BMS models for procurement are the same. They each pander to the contract divisions in the U.S., the UK has imported this "vertical" market division and many people are comfortable with this traditional 20 year old method for system procurement. This method was born out of the need to buy everything from each of the vertical markets so that each would work. These "vertical" markets are depicted in the drawing "3-tier proprietary". Integration of these vertical markets is not priced in the cost comparison. This familiar "3-tier" solution is a well trodden path of understandable risk however the customer pays.

"2-tier" Interoperability at the device level using fast secure reliable networks provides the opportunity for a "horizontal" system. This "flat architecture" means that different products of all the contracting divisions can be bought and installed and wired together.

The second tier is the now famous TCP/IP over Ethernet, which is a fast reliable securable network. Interoperation doesn't stop because of this upper level; integration with the enterprise network has long been possible now. Through the CABA oBIX initiative we expect to have interoperability schema standardised with OASIS and these are fundamentally the LonMark profiles that have been agreed by the LonMark International Trade Association of 300 members.

So how does two-tier procurement save money? And at the same time keep everyone comfortable with their part of the market, bearing in mind that the contracting business has long been familiar with the three-tier model of procurement.

First to make happy in the change to two-tier are the M & E contractors. The horizontal market is daunting at first like any other "change" but actually it is hardly any different. The M & E contractors are given the specification to use the standard LonMark System components and cables and connections and install them. No software, no complication just buying and installing.

This two-tier methodology requires plant room design to be different but again easier. No motor control centres are used, local panels maybe used, everything is distributed and maximum utilisation of package plant devices, e.g. pumps with built in controls and variable speed drives is the normal way. These products are factory built with high volume and high quality but with the minimum site time. The cost profile changes with more spent at the factory but overall the cost is reduced, 4% saving on the whole M & E cost for a Category A fit-out. In legal terms this puts the suppliers of these products as a straightforward manufacturer product warranty as no design or reconfiguring is done - just supply and install.

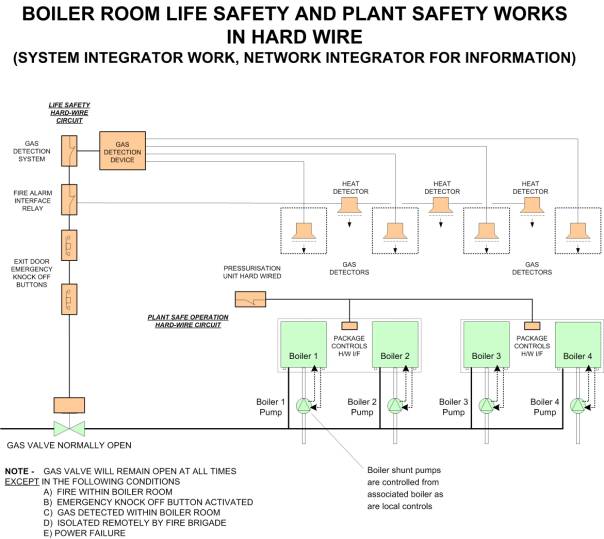

The plant room is designed to work "standalone" i.e. the boilers work directly with their own pumps as do chillers etc and all with their local respective safety devices. It works on the package controls only and hardwire safety devices, not efficient but a simple hardwire maintenance mode - all networks disconnected and the plant working at a basic on 24/7/365. In this model the electrical does most of the cables but mechanical keeps the high terminal devices with controls on-board. More details on the procurement technique are given in the up-coming September edition. How everyone wins in this two-tier process is explained in the up-coming October edition.

The software application and the network products are bought from the system or "Network" Integrator. The Network Integrator only works direct to the Main Contractor, because they will be integrating across the division of supply and install. The design warranty for a working integrated interoperable system is achieved here with the Network Integrator.

This is Part 1 VBHQ where we introduce the building, the cost benefit for interoperability and the cost benefit gained from the procurement technique achievable with open systems and choice.

In Part 2 VBHQ we will give you more introductory material and an inside view i.e. 10 years experience distilled into nuggets of useful knowledge.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]