|

May 2021

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

“The Future is Now”

Change

has thrown so much at us over such a short period that everyone, literally

every single human on the planet, has had to adapt to a new reality that simply

didn’t exist a little over a year ago.

|

Phillip Kopp, CEO Conectric Networks

https://conectric.com/

|

During last month’s editorial we

considered how the building industry and the people that use buildings must

adapt to endure the constant of change. Change has thrown so much at us over

such a short period that everyone, literally every single human on the planet,

has had to adapt to a new reality that simply didn’t exist a little over a year

ago.

In my article titled “The only constant

is change”, we explored the concepts of

structural versus behavioral adaptations. Over the last year we have mostly found

ourselves reacting quickly and behaviorally to changing conditions. And for the

most part, the structural systems needed to support the rapid environmental

changes we have endured simply did not exist. Infrastructure and resources

needed to address the global crisis was missing, supply chains were disrupted,

buildings were emptied, while others became highly demanded and under capacity.

The same for varying types of human workforce labor and skillsets. This leaves

a lot of work to be done into the future, and that most surely being a future

in which every approach to planning considers the need for flexibility and

resilience at the forefront.

In my article titled “The only constant

is change”, we explored the concepts of

structural versus behavioral adaptations. Over the last year we have mostly found

ourselves reacting quickly and behaviorally to changing conditions. And for the

most part, the structural systems needed to support the rapid environmental

changes we have endured simply did not exist. Infrastructure and resources

needed to address the global crisis was missing, supply chains were disrupted,

buildings were emptied, while others became highly demanded and under capacity.

The same for varying types of human workforce labor and skillsets. This leaves

a lot of work to be done into the future, and that most surely being a future

in which every approach to planning considers the need for flexibility and

resilience at the forefront.

While assessing our need to develop

more structural adaptations, I have suggested that our buildings may become architectural

shells, with flexible, adaptable infrastructure and software programmable

technology that can serve many uses at once, or change uses over time as needs

or the environment around the building changes over time. A demand driven

building may need to be completely repurposed from an office to a hospital in

under a week. And then into a cold storage, while finally ending its life as a

multi-family dwelling. Or perhaps, all of the above at the same time! The

adaptable building would have all the capabilities inbuilt to undertake these

requirements by plugging in new systems and modules brought in on delivery

trucks. With wireless networks bridging these systems together to eliminate the

constraints of fixed reading and control points, programmed remotely in real

time, and automated to meet the specific requirements of the current use, capacity,

and environment. It may even be customized for local energy supply and demand conditions,

as mated with other on-demand buildings and movable energy resources.

Taking this a step further, on demand

buildings would require the building industry to restructure so that the

initial construction process is really deemphasized. The owner is primarily

charging for land use, and the ongoing operation of the building and its

various uses would be provided as temporary service offerings by “building use

providers”. Making the “building use plugin” operator the real value provider,

and primary cost driver in occupying or using a building.

If you want to draw an easy parallel,

look at the evolution of the cell phone. You used to get a vertical offer

provided by a monolith like Ma Bell. She would sell you the vertical system, “communication

in a box.” You would pay an exorbitant amount for everything, hardware,

service, contracts, plans, coverage and overage. And be stuck with your

provider that only works with its proprietary sets. If the service was bad,

your call dropped. If you wanted to call out of area to into another network,

get ready to pay a huge toll. Not at all different from the state of building

systems today.

In comes a little technology, a

little anti-trust regulation and fierce competition. Now you buy your phone

hardware and can take it to whatever provider gives you the cheapest services.

The phone maker no longer provides the apps, but an ecosystem to thousands of

app providers, each whom you pay independently of the handset maker and the

carrier for the individual use function you want to get, and for the amount of

time you want to use if for (i.e. monthly). As of now, most carriers have even

removed the annual contract and there are few restrictions to switching service

providers at will. I proffer, this path will be a direct analogue of the

building industry.

The

original “bag phone” is not that much different than the operational technology

found today in buildings. In the future our buildings will be more flexible, using

modular technology and independent service vendors.

In comes this month’s automatedbuildings.com

theme, the “digital family “(twins, triplets, quadruplets, parents and great grandchildren). If

you have already managed to wrap your head around the idea of a flexible,

modular building use service let me extend us another step forward into the

realm of possibilities.

Today we are frequently having

conversations about “Digital Twins.” Although there are many better articles to

learn about digital twins, for the readers sake I can describe the cliffs notes

version. The digital twin is a representation of physical assets, their

environment and current state of use as digital parameters, recorded in near

real-time into a digital database, so that they can be visually represented in

software to the user, and recorded for future analysis.

Some would argue that there are

already millions of digital twins present in existing databases, troughs of

data points collected about everything from your building automation system, to

your personal health devices (i.e. Fitbit’s data could provide a digital twin

of “you”), and even your car. You might call this digital twin “V0.1”. This

data is usually collected for the benefit of the asset or devices [OEM]

manufacture, or a related service, and may not have been organized or designed

in such a way that it can be easily analyzed by 3rd parties or

shared with others by the user that creates it. Although the data may be

analyzed by the related parties through their own tools, it is challenging to

build additional context around the data because it cannot be seen through a

different vantage point. It cannot be combined with other data that is possibly

impacting the current state of that data, or visualized in an advanced solution

that allows multiple parties to interact with the information at the same time

from different locations. You might liken this to “Fault Detection Diagnostics”

(or FDD, another popular topic of conversation). FDD is the ability to look at

the operating characteristics of something and identify whether it is regular

or “irregular”, so that it may be serviced or improved. Although some value is

generated for the manufacturer, owner or user of the asset, a substantial

amount of “hidden value” cannot be found without being able to join that asset

or devices conditions with those of other around it or affecting it.

With this in mind, the current

conversation is around digital twins where data from all kinds of related

parties and systems is conjoined, connected and can be looked at as a much

bigger, broader and deeper data set. One in which the current state or

condition of a specific asset can be more closely linked to that of another or

any other number of related factors. Perhaps this possibility of sharing data

between data sets into a common tool, visualizing it as Augmented Reality or

global dashboards or even in Virtual Reality is what we commonly think of today

as the digital twin and should be called “V1.0”. This kind of digital twin will

help make it very fast and easy for different teams, with different skillsets,

and different perspectives to look at data sets and quickly identify where

problems and opportunities might be found, or where resources need to be

immediately dispatched or controlled to enhance safety, optimization,

performance, etc…

A digital twin of Tampa Florida built by Imerza using the Unreal

Engine (source: architosh.com)

In comes the master of future systems

and a close and trusted colleague, Nicholas Waern,

“the building whisperer” in his recent interview with Ken Sinclair on “Digital

Triplets”, and their various family extensions. Could

we already be leapfrogging V1.0 into V2, V3, V4 and beyond? What exactly does

this mean in the context of “flexible buildings” in an ever-changing

environment? In my humble opinion, almost everything actually!

Although the first two steps by

themselves are already quite a lot to grasp, what Nicolas is really talking

about is more than just an extension of a software solution. It is one part

science, and one part magic. In essence, the digital triplet is our coming

ability to predict the future.

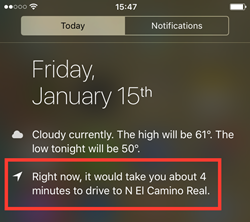

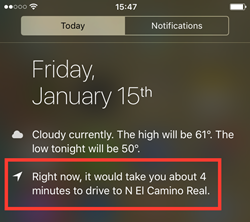

“Prediction

then” “Prediction now”

Predicting

the future is no longer just in the domain of the gypsy fortune teller, it is

built into the software we use every day and soon to be much more powerful with

the Digital Triplet

While this feature exists to some

extent in our V0.1 as “predictive analytics”, the potential scope and accuracy

is quite limited by the amount of data that can be analyzed and projected. That

is because the “context” is missing as to why the source data underpinning the

prediction is what it is. It is impossible or difficult to tell what the “root

cause” is. That means that even if an imminent failure is predicted based on

the current state of a machine, because say a vibration sensor, or a power

quality reading has deviated from the norm, we still don’t really know the

underlying cause. Is it because of an operator error? An environmental

condition that device was subjected to? The failure of an individual component

because of a bad production batch? While we can replace the device and solve

the problem before it becomes catastrophic, we do not really learn how to

prevent it from ever happening again in the future.

With the digital triplet all

information, from all sources are taken into context. It becomes possible for

advanced software to look at the surrounding conditions, the operator behavior,

the systems linked to that system and even the individual components and their

life cycle history. Did the motor fail because the brushes for that motor were

produced on an incredibly hot day and encountered a small, but undetectable

stress defect? Which became apparent only under the very specific conditions

that the failed motor just underwent. Can we then apply that to all similar

motors, produced with the same component, and being used in other sites to

identify potential failures? Then predict those failures based on the projected

operating conditions in those installations, which may line up with the

specificities found in the failed example? With a digital triplet this vast

amount of corollary data will lead to incredibly accurate and detailed

predictions about the future of everything!

I started my company Conectric Networks over 5

years ago with the specific concept in mind to enable a “data utility” to be

able collect and sell information to “AI” consumers (or as we are now calling

them, digital triplets), everywhere. We collect large amounts of human, environmental,

machine state and energy data in near real-time using wireless sensors from

applications where it otherwise might not be available or extractable. This

data then gets forward into databases and analytics, or “digital twin”

platforms exactly as described above. Specifically, I believe that the energy

grid of the future must be able to meet a very complex requirement to

match supply and demand in a highly dynamic world where even cars are mobile

“power plants”, able to both consume and produce energy that will be used to

provide building related and lifestyle services. I believe that we must have a

massive network of granular data feeding into the global digital triplet to

effectively predict future energy needs, and therefore match supply and demand

based on past, current and future resources.

This data cannot be limited to just

the feeder system, or even the individual low voltage transformer as it is in

today’s grid, but literally every single potential energy consumer, asset,

device, machine, etc… connected to the system. In the end, the future of

civilization and our ability to grow and prosper will depend on having high

quality, reliable and abundant energy. And more so than ever, this energy

source must be renewable and non-harmful, distributed, and resilient. It must

be able to meet the dynamic requirements of the “on-demand” building structure,

the “on-demand” transportation, the “on-demand” end use needed, just at the

right place, at the right time.

And this current reality is how I see

the immense power and value of the digital triplet emerging. These things

together are the enablers to our future growth and advancement as a resilient,

adaptable civilization. Where we can not only manage risks as they emerge, but

we can predict them before they happen and harden ourselves structurally so

that even the very worst scenario just isn’t that bad after all.

And although we are not quite yet

able to impact the regulated energy grid system in the way I would like to, we

have developed an amazing solution to be able to deliver digital triplet use

cases in commercial office buildings, by helping building owners and tenants

provide on-demand, flexible office environments. We can connect buildings with

their occupants on an as needed basis, and ensure that the services such as

Facilities Maintenance (FM) and janitorial services needed to support a highly

dynamic office occupancy are equipped with the future prediction abilities to

support a seamless, interactive and transparent hybrid office experience. And

in my attempt to step towards that interactive grid, we are even tying together

those hybrid work experience environments with building management systems to

automate the heating, lighting and access control to optimize equipment

efficiency, reducing the energy and carbon consumption, based on real-time and

predicted future demands (that subject could encompass a whole different

article on its own!).

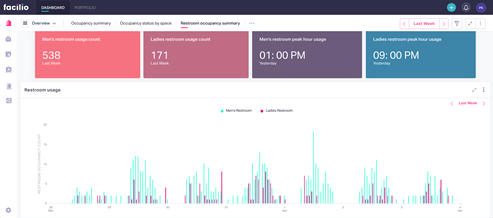

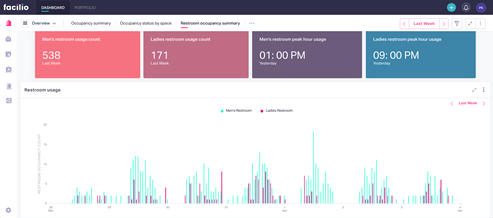

Male and female office restroom usage is analyzed and predicted

based on low cost, non-invasive Conectric wireless sensors and the AI enabled

Facilio.com analytics platform that records and reports usage in near real-time

Magic is no longer just for fairy

tales, but humans and our machines have literally attained the capability to

see into the future. And as more digital triplets and their families emerge,

this capability will become more and more powerful. As I like to envision it,

for the greater good of humanity. Or as I often say, for a safer, healthier,

more productive, and environmentally sustainable world!

Please do not hesitate to reach out

to me to learn more about how you can realize these benefits in your own

scenarios and see why the Future is Now.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]

In my article titled “The only constant

is change”, we explored the concepts of

structural versus behavioral adaptations. Over the last year we have mostly found

ourselves reacting quickly and behaviorally to changing conditions. And for the

most part, the structural systems needed to support the rapid environmental

changes we have endured simply did not exist. Infrastructure and resources

needed to address the global crisis was missing, supply chains were disrupted,

buildings were emptied, while others became highly demanded and under capacity.

The same for varying types of human workforce labor and skillsets. This leaves

a lot of work to be done into the future, and that most surely being a future

in which every approach to planning considers the need for flexibility and

resilience at the forefront.

In my article titled “The only constant

is change”, we explored the concepts of

structural versus behavioral adaptations. Over the last year we have mostly found

ourselves reacting quickly and behaviorally to changing conditions. And for the

most part, the structural systems needed to support the rapid environmental

changes we have endured simply did not exist. Infrastructure and resources

needed to address the global crisis was missing, supply chains were disrupted,

buildings were emptied, while others became highly demanded and under capacity.

The same for varying types of human workforce labor and skillsets. This leaves

a lot of work to be done into the future, and that most surely being a future

in which every approach to planning considers the need for flexibility and

resilience at the forefront.