|

May 2019

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

|

A Lightweight Yet Informative HTML5 User Experience

Using a standard naming convention defined by the haystack

tags7. These tags are also referred to as semantic tags or metadata

tags and were developed and agreed upon by the Project Haystack8

community, where Conserve It is a founding member9

|

Pravesh Badjoonauth,

Product Support Manager,

Conserve

It

|

Introduction to HVAC Systems

In

commercial buildings, HVAC is by far the most energy intensive system,

accounting for close to half1 of the total energy consumption.

HVAC

systems, however, are vast and typically consist of several smaller

subsystems that are intended to be integrated all together and work in

a synergistic manner. These subsystems are categorised into Air Side

systems (E.g. AHUs, FCUs) and Water Side Systems (E.g. Chiller Plants).

A

Chiller Plant comprises equipment such as Chillers, Pumps, and Cooling

Towers and is an integral part of a building’s HVAC system being

responsible for maintaining the indoor building space conditioned at an

appropriate temperature. Consequently, chiller plants account for a

sizeable chunk or around 65% of the building’s HVAC system electrical

energy consumption.

For

this reason, every efficiency improvement in HVAC performance,

including Chiller Plant performance, can significantly reduce the

energy profile of the building, turning HVAC optimisation into a value

generating opportunity. Typically hidden away in plant rooms, HVAC

systems can be complex, challenging and are frequently overlooked.

Energy saving opportunities are often missed in this complex technical

arena. This is where Conserve It2 comes into the picture and

helps

unlock the energy saving potential of a building’s HVAC system through

state-of-the-art IoT solutions developed in-house.

Introducing Conserve It and PlantPRO

Conserve

It, an organisation headquartered in Melbourne, Australia identified

the need for a solution that will not only provide better visibility

into how the energy inside a plant room is being consumed but also take

full control of the chiller plant equipment and operate the most

efficient equipment at their optimum operating efficiency. This

solution was baptised as PlantPRO3. Created with an in-depth

understanding of all thermodynamic variables involved in managing plant

room HVAC equipment, PlantPRO enables complete and optimum control of

every device and its integration into a single synergistic system, with

added functionality for Measurement & Verification, Maintenance

& Diagnostics and Reporting and Charting.

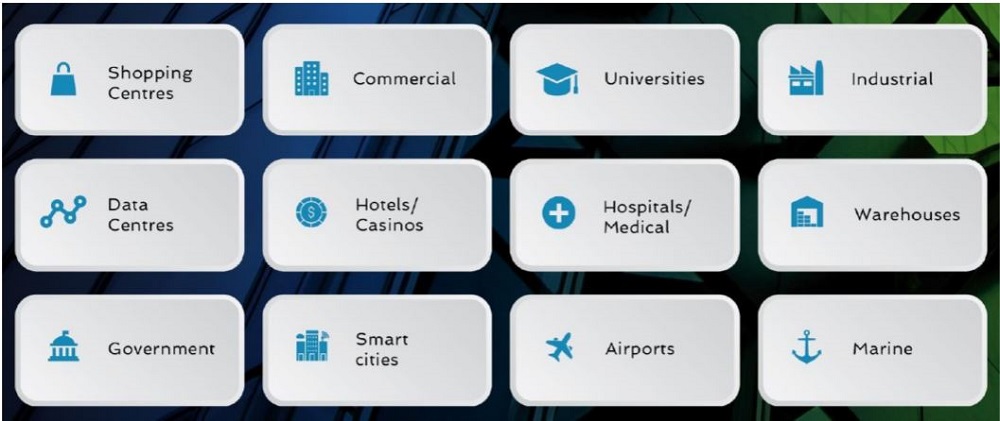

PlantPRO - Global Installations by

Industry

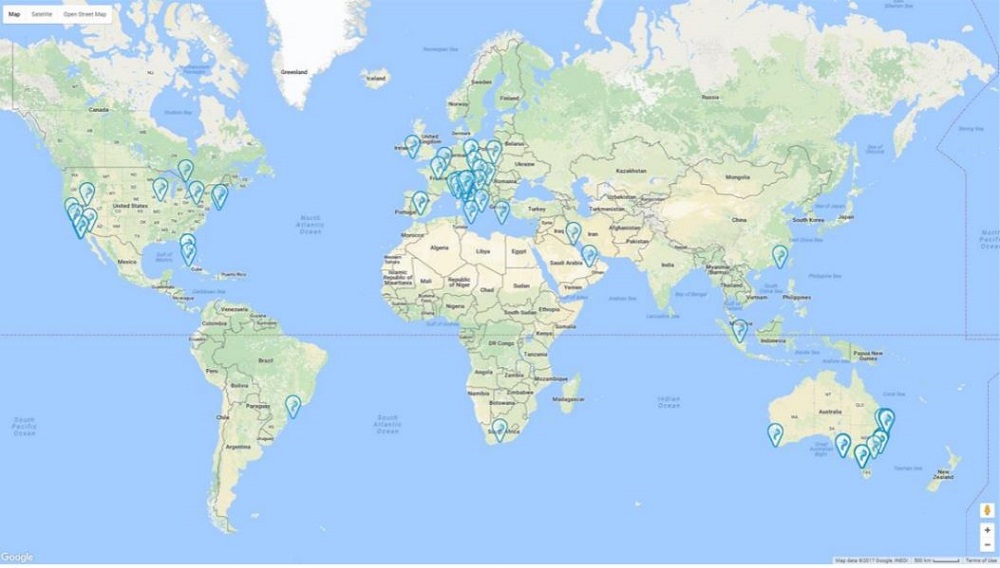

PlantPRO – Global Footprint

Cost

Matters

As

with any product, quality comes at a price, and the PlantPRO solution

is no different. PlantPRO is a specialised solution developed by

engineers and software developers in conjunction with HVAC specialists

with over 30 years of experience in the trade and the effort put in to

develop the PlantPRO solution does translate into a high investment

cost by Conserve It and a justified product price tag as a result.

Despite its price, however, PlantPRO has been well received globally

and as a testament to this has been deployed in over 200 locations

worldwide and has received multiple industry awards and nominations.

With its numerous built-in optimisation strategies, PlantPRO has

achieved energy consumption and cost reduction of over 30% which

generally covers the cost of the PlantPRO solution within a short

payback period. Nevertheless, it cannot be denied that for anyone

looking at acquiring the PlantPRO optimisation solution will be looking

at a sizeable upfront investment, and this upfront cost can be a

hindrance for cost-sensitive projects such as those with smaller

footprints or projects in emerging markets. This is why Conserve It

developed and released PlantPRO

CORE4 – a low cost, high feature

chiller plant control system that retains many of the good bits of the

full PlantPRO solution.

PlantPRO CORE – Low Cost, High Feature

PlantPRO

CORE incorporates the trusted and proven control algorithms of PlantPRO

with a lightweight yet informative HTML5 user experience. As with

PlantPRO, PlantPRO CORE includes the ability to control chillers, pumps

and cooling towers in a very wide array of plant configurations. Users

are able to monitor current plant operating conditions in PlantPRO core

via a responsive HTML5 user interface on either desktop, mobile or

tablet without the need for JAVA or similar supporting software.

Included in PlantPRO CORE are the reliable charting and alarming

features which allow end users to chart historical data effortlessly

and be informed of any anomalies in their system.

PlantPRO CORE – Deployment

PlantPRO

CORE has been developed on Tridium’s5 Niagara Framework and is

deployed

on Conserve it’s highly reliable edge IoT controller - the CI-5346

series hardware. The CI-534 provides 34 points of onboard IO and is

expandable allowing for up to a grand total of 306 points of IO. The

CI-534 controller supports all standard IP Protocols such as BACnet IP,

Modbus TCP and LON over IP and as such facilitates integration with

most BMS systems in the HVAC industry.

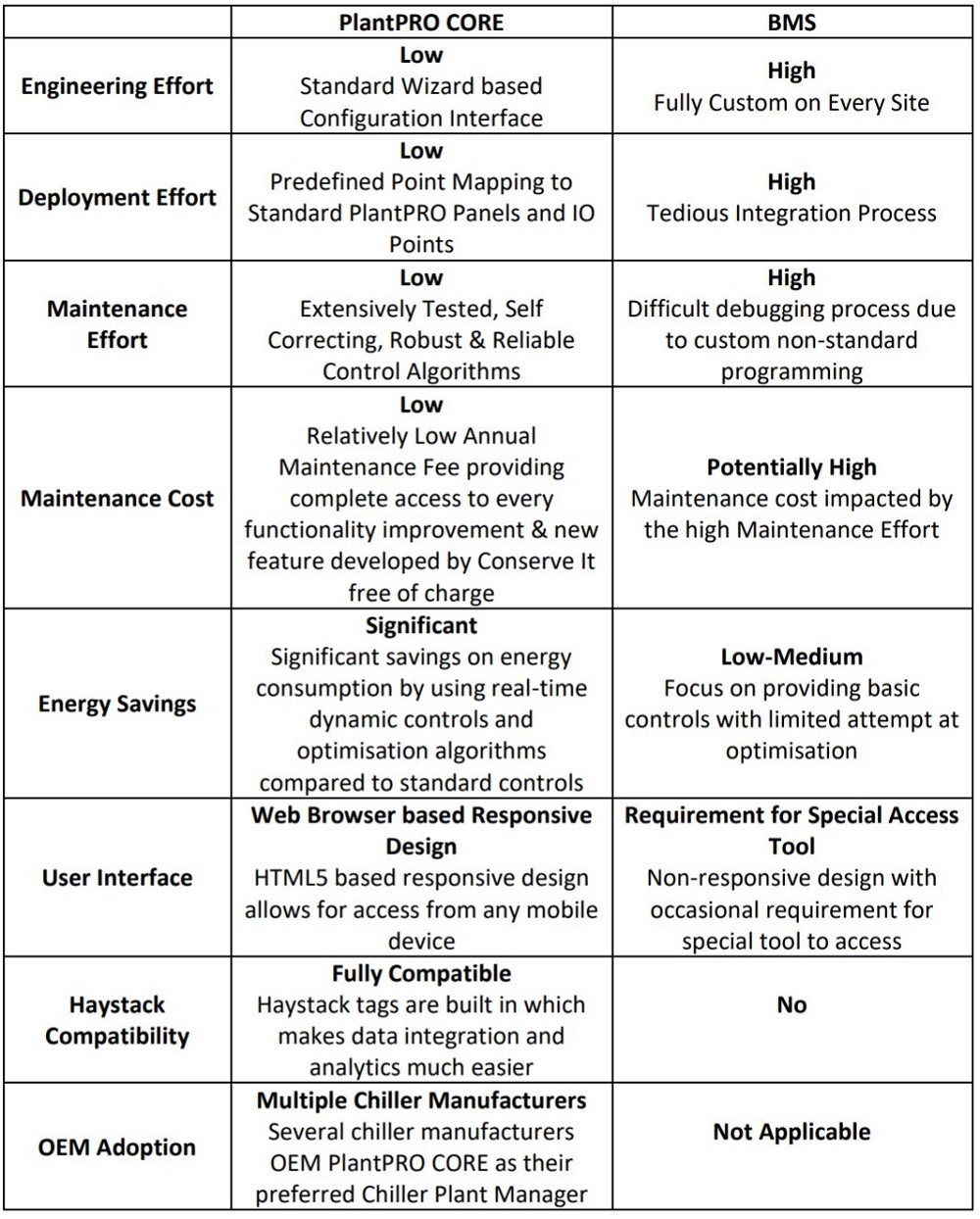

PlantPRO CORE VS BMS/BAS

PlantPRO

CORE is intended to operate in the same sphere as Building Management

Systems (BMS) or Building Automation Systems (BAS) and inevitably the

question that gets asked is why to opt for PlantPRO CORE when the BMS

system can complete similar functions. Whilst this is a fair question,

there are actually many factors that differentiate PlantPRO CORE over a

typical BMS/BAS. These can be broken down into distinct categories as

described in the table below.

PlantPRO CORE – Haystack Compatibility

As

outlined before, PlantPRO CORE is fully Haystack compatible which means

that all sensor data points within PlantPRO CORE are tagged using a

Haystack tag. Tagging is a methodology for defining the meaning of

smart device data or put simply it allows the vast amount of

information coming from sensors into PlantPRO CORE to easily be

identified using a standard naming convention defined by the haystack

tags7 . These tags are also referred to as semantic tags or metadata

tags and were developed and agreed upon by the Project Haystack8

community, where Conserve It is a founding member9 alongside companies

such as SkyFoundry and Lynxpring and Board Members such as Intel and

Siemens.

[an error occurred while processing this directive]References

1.

https://www.energy.gov.au/publications/hvac-factsheet-energy-breakdown

2.

https://www.conserveit.com.au/

3.

https://www.conserveit.com.au/plantpro

4.

https://www.conserveit.com.au/plantprocore

5.

https://www.tridium.com/

6.

https://www.conserveit.com.au/edge

7.

https://project-haystack.org/tag

8.

https://project-haystack.org/

9.

https://project-haystack.org/about

About the Author

Conserve

It Product Support Manager, Pravesh Badjoonauth, graduated

with a Bachelor of Engineering (Electrical) from RMIT University. He

joined Conserve It in 2012 and has been promoted a number of times over

the years before taking on his current role in July this year. Conserve

It provides a wide range of products and services including monitoring,

reporting and controlling air conditioning and boiler plants to

minimise energy consumption. Today the company has diversified into

complete HVACR plant management. Since joining Conserve It Badjoonauth

has continued to hone and refine his skills at a rapid pace and today

is a certified global product trainer, system design advisor,

commissioning specialist and technical team leader.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]