A question asked and answered at this year’s KMC Genius Summit.

Therese Sullivan,

Therese Sullivan,Principal,

|

February 2018 |

[an error occurred while processing this directive] |

| Can Your Buildings Go from Bad to Great

like the USS Benfold? A question asked and answered at this year’s KMC Genius Summit. |

Therese Sullivan, Therese Sullivan,Principal, |

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

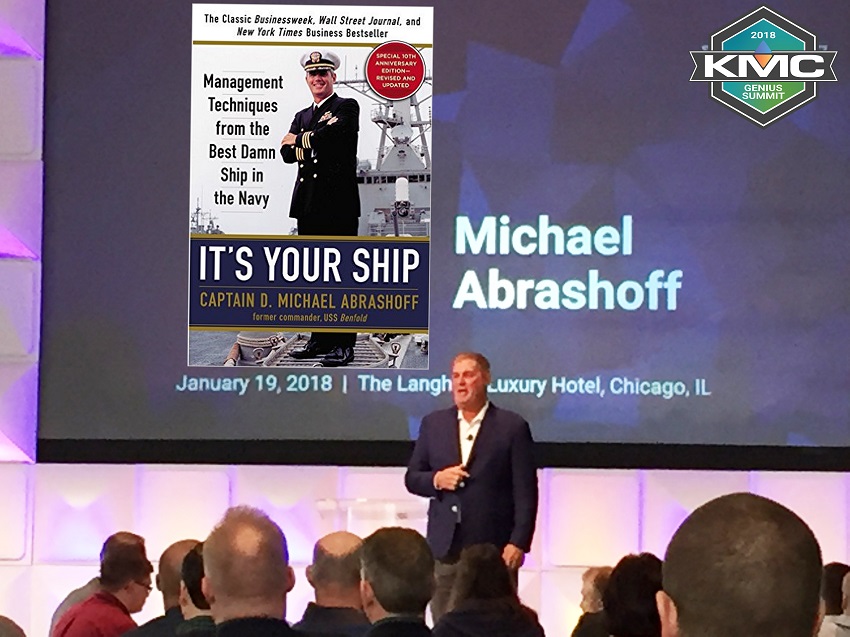

If you think about the challenge the wider buildings industry faces as it tries to upgrade our existing built environment to meet today’s comfort, flexibility and energy efficiency standards, it has some similarities to the situation Captain Mike Abrashoff faced when he took command of the USS Benfold. As he recounted in his book, It's Your Ship, and at the KMC 2018 Genius Summit in January, the ship was ranked near the bottom of the performance ratings for safety and crew retention among the U.S. Navy’s Pacific fleet when he first came aboard. He needed to initiate a turnaround, but he was constrained by his military context and could neither make on-the-spot personnel changes nor dole out financial incentives like a business executive. Yet, Abrashoff led the Benfold from its place as one of the worst ships in the Navy to one of the highest performers. Wouldn’t every owner of old, energy-wasting and out-of-commission properties like to know how to do that?

There were a few keys: one was being a servant leader, respecting and listening to the ideas for improvement suggested by every crew member at every rank. Another was applying rigorous process control methodology as he and the crew reevaluated every process, role, and aspect of daily work aboard the ship. That means lots of trials, tests, and data measurement. It was an appropriate motivational story for the KMC community in attendance at the Chicago summit because going from bad to great performance through disruption of old hierarchies, and ways of operating are needed in the buildings industry today. Also, developing new tools that support greater visibility and tighter control over every process and aspect of building operations is just what KMC Controls does.

Abrashoff told the story of a young sailor who challenged the process

of painting the ship every few months—a Navy tradition. He pointed out

that rust stains caused by salt-water corroding ferrous metal nuts,

bolts, and other fasteners were prompting the need for more paint. Why

not switch to non-corroding stainless steel fasteners? Sailors could

have time for more rewarding work if they were not engaged in this

continuous painting. Not only did the Benfold

make the change, soon the whole Navy did the same.

I recalled this story a few days later when Scott Cochrane, President of Cochrane Supply, a KMC Partner company, made a comment, “Today 27-year-old IT enthusiasts are telling 60+-year-old tradesmen what needs to be done to manage a building.” Cochrane emphasized in an AHRExpo education session that systems integration work was becoming a collaboration among those that approach it as a new data engineering challenge and those with deep experience moving air and water through a building. Those who grew up with smartphones in their hands seem better equipped to fill the role of data architects. Cochrane was echoing Abrashoff’s messages that leaders need to be open to the fresh ideas of the Millennial-generation hires in their midst and engage them at their most creative level.

Erich

Kreuter, KMC Controls VP of Product Development, is a Millennial and he

had a big hand in KMC’s latest generation product, the KMC Commander™.

KMC Commander is an open, secure and scalable IoT platform. Just like

repainting Navy ships every two months, ‘bucket work’ – the business of

sitting in mechanical-room closets on over-turned plastic buckets as

you program controls systems – is activity Kreuter would like to see

minimized. Once you have installed KMC Commander on the on-premise Dell

Edge Gateway and devices have been discovered, provisioning and

scheduling of individual VAV controllers and room sensors can be done

remotely via an Internet browser. That is an innovation that is as

welcome as stainless-steel fasteners.

As

Kreuter explained in his session at the KMC Genius Summit and for this

video, many light-commercial buildings provide poor environmental

comfort because their air-handling needs are served by outdated VVT

(variable volume and temperature) systems. Like the USS Benfold, improving the performance

of these buildings starts with a better way of dealing with the

constant need for service and maintenance. No one wins with the

reactive status quo approach of just letting individual components wear

out, occupants complain, and the maintenance contractor send a truck

for each problem. Changing out the entire mechanical system and

installing a dedicated onsite building automation system (BAS) is

typically too expensive for such buildings. Gaining remote visibility

and control by retrofitting the VVT systems with KMC Commander is the

type of innovative solution that can move a building from being a

problem property to one that is consistently comfortable and delivers

high NOI (net operating income.)

Kreuter emphasized that lower energy costs and happier occupants are just the start of the benefits that enterprises can realize once their buildings are connected through the KMC Commander IoT platform. He recommends, “If you have a chance to trend it, trend it. You don’t know how you might use that data for other services in the future.”

KMC Commander has a polished, mobile-responsive user interface that puts all the right data at the finger-tips of the right team member. It deploys a deck of cards metaphor that makes it easy to configure points. You can configure up to eight points of interest on each card, incorporating a number of devices such as a room sensor or controller. Additional points are then added to the back of the card and accessible by simply flipping it over. KMC Commander also tracks, trends and triggers that data. The KMC Commander app is available on any mobile device with an internet connection and Google Chrome browser.

[an error occurred while processing this directive]Built into KMC Commander is support for common protocols for sensors, devices, controllers and buildings systems, including BACnet, Modbus, and SNMP. KMC is part of collaborative initiatives like Project-Haystack™, which is working towards consistent metadata tagging standards for data models, and EdgeX Foundry™, which offers a flexible software development framework for anyone writing applications designed for edge computing. Through participation in these open-source organizations and by maintaining strong partnerships with IT leaders like Dell and Intel, KMC is ensuring that KMC Commander is secure, optimized and open—all the qualities customers need to consider when selecting an IoT platform on which to build. Scott Muench of J2 Innovations delivered a Project-Haystack session at the Genius Summit, and Tom Neidermann of Dell was on hand to answer questions about EdgeX Foundry.

There is one more analogy to pull from the story of continuous improvement on the USS Benfold as it relates to the challenge of operating buildings today: the greatest leverage for change was not found on the top of the supervisory hierarchy, but rather closest to where the work was done. In similar human terms, IoT platforms like KMC Commander are going to empower the crew — building engineers and facilities teams. They’ll have more flexibility to configure and reconfigure points-of-interest to capture and trend just the data they want to pursue any current line of inquiry as they work toward operational excellence. In machine terms too, the new paradigm is to make the most of the brain power at the edge close to where the work is done. There is no need to send all data to the cloud. Edge computing has potential to completely upend how workflows are architected among devices. Captain Abrashoff attributes the feat of going from one of the poorest performing ships in the Navy to one of the highest rated to being open to new ideas and to act on the best of them. The KMC community in attendance at this year’s Genius Summit seemed ready to embrace that philosophy, particularly with respect to looking for use cases for KMC Commander.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]