|

January 2022 |

[an error occurred while processing this directive] |

| City of Cuneo Taps Factory Waste Heat to Warm Residences |

By Therese Sullivan, Tridium, Inc. https://www.tridium.com/us/en |

[an error occurred while processing this directive]

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Links |

| Software |

| [an error occurred while processing this directive] |

“The plant will continuously pump hot water, keeping it circulating

throughout the network like a powerful beating heart with sufficient electricity

and heat to serve the multitude of buildings that will want to connect.”

Europe has ambitious plans to meet EU 2050 energy and

climate objectives. In Northern Italy, the practice of district heating

is one way that regions have put ‘Circular Economy’ concepts into practice and

curbed their fossil fuel use. Mountain towns in the Piedmont region of Italy

run central energy plants that deliver thermal energy to businesses and

residents via highly insulated underground piping networks. High-efficiency CHP

(combined heat and power) plants that tap into local natural gas for energy

production have been particularly successful in this region that borders

Switzerland and France. To reduce dependence on fossil fuels even further,

these cogeneration plants also combine other sources like waste heat from

industry. The process saves energy and

substantially reduces CO2 emissions and pollutants, while supplying residents

with district heating at lower cost.

Based on this strategy,

a joint venture was formed in 2017 between High Power SpA — a regional

leader in the construction and operation of district heating and cogeneration

plants — and AGC Glass Europe. The

resulting company, Wedge Power, was chartered to build and operate an

electrical/thermal CHP plant to recover and to reuse waste heat from

plate-glass manufacturing operations of AGC Flat Glass Italia. Construction of the CHP plant was just one

aspect of the refurbishment of AGC’s Cuneo plant. The redesigned factory was

also expected to boost capacity and reduce energy consumption and emissions. The plant opened in October of 2018.

Niagara Framework® is at the core of the centralized energy management system

that monitors and controls operations and ensures consistent, optimized

delivery of power and district heating to Wedge Power customers.

Challenge

AGC’s Cuneo plant entered service in 1963 and grew to be

the largest glass manufacturing plant in Italy. Cuneo Glass has one float glass

line which serves downstream facilities for processing the panels into glass

products for architecture and furnishings, for the automobile industry, as well

as for retail displays. During design and construction phases, the Wedge Power

project team was challenged to build and equip a CHP plant that could produce

sufficient electricity to cover glass manufacturing operations, as well as to

supply the electricity needs of 20,000 homes and enough heat to power a hot

water system that would heat some 400 homes. The project called for excavations

and installation of 45 kilometers of insulated pipes to circulate the plant’s

thermal energy and an equal length of fiber optic cable to serve the CHP

plant’s data network. The data network interconnects all the heat and energy

distribution substations, and it provides the communication infrastructure for

other services.

Solution

Sinergie Energy Solutions and Quicklink

Solutions designed and integrated the data management system for Wedge Power’s

CHP plant operators. The solution starts with a JACE® 8000-based control kit

running Niagara Framework deployed at each substation. The sub-central

management logic exploits Niagara Analytics to highlight anomalies in energy

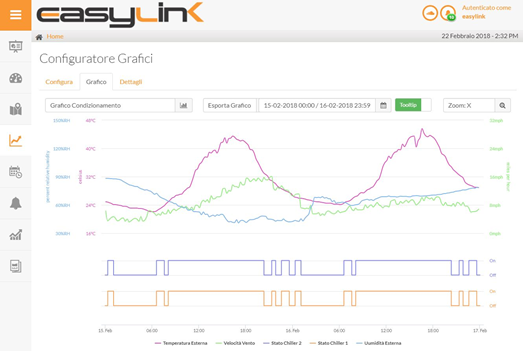

consumption and to generate alarms when faults are detected. The EasyLink

supervisor, a management system developed by Quicklink based on Niagara, allows

the optimized monitoring and control of the substations.

The project team took care to add appropriate metadata

tags when modeling equipment and plant subsystems in Niagara to enable easy

data aggregation and analysis of operations by the Wedge Power plant operators.

This laid the groundwork for a custom user interface featuring advanced HTML5

graphics, configurable through a powerful chart builder. This central-console

UI supports customizable reports and dashboards for various users, geolocation

of sites and the creation of custom data maps.

RESULTS

Wedge Power’s central management console

presents near real-time data from the 500 thermal substations connected into

the CHP network. From the User

Interface, operators can

monitor and control activities; run

analytics to detect anomalies and trigger action to avoid failures before they

happen; and keep the CHP network running in its optimal state.

The various stakeholders in the Wedge

Power Cuneo Project are benefitting from this innovative energy management

solution for the city’s CHP plant:

·

Electricity consumers are realizing price savings. AGC Glass,

particularly, is saving significantly on the amount of energy it needs for its

own cooling operations during glass production because waste heat is recycled.

·

District heating subscribers are realizing heat supply savings with

zero risk of heat-related poisoning, gas leaks, explosions, and noise. They

also receive heat with high reliability and 24-hour remote control, as well as

free connection and no charge for ordinary and extra-ordinary maintenance.

Regarding progress in meeting

environmental goals, the project is responsible for the recovery of

approximately 50 GWh per year of energy, plus:

·

50% less nitrogen oxides emissions (≈10 ton) locally

·

36% less primary energy to produce the same quality of heat as

traditional power plants

·

25 tons/year less of carbon dioxide emissions globally

·

12 tons/year less sulfur dioxide emissions locally.

ABOUT QUICKLINK SOLUTIONS

Since 2008, QuickLink Solutions has been

delivering innovative and advanced solutions for building and industry energy

management. With its Niagara Framework-based solutions, it strives to make the

configuration, commissioning, and maintenance of energy management systems quick

and easy. It works as a solution partner, providing technology products through

a network of certified System Integrators.

ABOUT TRIDIUM

Tridium open-protocol

products allow diverse monitoring, control and automation systems to

communicate and collaborate in buildings, data centers, manufacturing systems

and smart cities, bringing intelligence and connectivity to the network edge

and back.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]