"It costs more to start it so I never turn it off". Often it's just not true. |

Charles Faulkner Article as published

at |

AutomatedBuildings.com

|

[an error occurred while processing this directive] |

"It costs more to start it so I never turn it off". Often it's just not true. |

Charles Faulkner Article as published

at |

Everyone has heard it: "It costs more to start it so I never turn it off". Often it's just not true. There are lots more, but this feature discusses a few common myths about electrical demand, explaining how to get to the truth behind them.

|

[an error occurred while processing this directive] |

Fiction:

"It costs more to start it so I never turn it off".

Fact:

Do the math: Does the added demand cost amount to more than the

energy you'll save by turning it off?

Example: - 100 kW load - Could be turned off for 2 hours per day, 30 days per month - Will add 20 kW to the peak if restarted (depends on other process and startup characteristics of the load.) - Demand charge: $10.00/kW per month - Consumption charge: $0.05/kWh per month

Cost of added demand = 20 kW x $10.00/kW = $200 per month. Amount saved by turning it off = 100 kW x 2 hours x 30 days x $0.05/kWh = $300/month. Turn it off and save $100 a month.

Fiction: "Short

duration loads fully register on my demand meter".

Fact: It takes more than fifteen minutes after the load is turned on

before most meters will register the full demand.

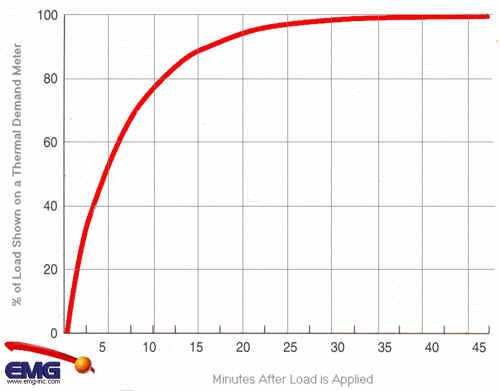

Most electrical meters respond to loads in a non-linear fashion, meaning that short-duration loads may barely move the demand needle (see the chart below). Effectively, it'll take more than 15 minutes to register the full load, but the only way to be sure is to speak to your electricity supplier.

[an error occurred while processing this directive]Be aware of this when estimating the savings associated with upgrades. For example: electric to gas conversions of booster heaters in commercial dishwashers. These often run in short spurts of a minute or two and a 30 kW heater may only increase the demand by as little as 5 kW

The final point is not a matter of fiction, but rather a basic principle: Know when your demand peak occurs. Some loads have no demand cost because they don't contribute to your peak. Examples may be outdoor lighting, ice making for thermal storage or other off-peak processes. Optimizing or upgrading these loads will save energy (kWh) but will not reduce your peak billing demand.

Fiction:

"Stagger the startup of your

loads by 15 minutes to avoid raising the peak demand".

Fact: Ask one question: How long does the load take to reach steady

state?

Most electrical loads will draw more current when starting but what matters is how long it takes the current to fall back to normal operating levels. The amount of time will vary widely, but you can find out with an Amperage logger or similar device. If it takes two minutes for a load to reach steady state, wait at least this long to start the next load.

To get the most from this strategy, move the equipment start times as close together as possible by starting with the last load and working back, allowing sufficient stagger times for each load. This means each load is being started as late as possible.

Sometimes, the added demand won't amount to much anyway and you might save more by keeping the loads turned off until the last possible minute. The previous example can be used to determine this.

© 2002 EMG Energy Management Group Incorporated www.emg-inc.com

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]